14

the valve should be replaced if any signs of over-

load or leakage is detected. The sensor needs to

be replaced after each explosion.

• The brush shoe has been designed to last at least

one year of continious operation, and should be

replaced annually. In case any substantial wear is

detected within a shorter period, the brush shoe

should be replaced anyway, and the reason for the

wear examined.

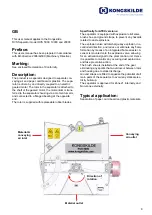

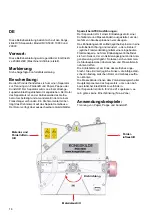

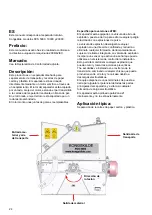

• The ground straps connecting all major parts of the

separator, should always be securely installed dur-

ing operation. The grounding points are indicated

by an earth symbol sticker as shown below. Annu-

ally check for damaged or loose connections, and

measure the resistance between the top of both M8

threads. The resistance in each connection must

not exceed 10

6

Ohm acc. to EN 60079. If the value

is exceeded, check for falty connections.

Lubrication of the gear:

The gear is provided with mineral oil, ISO VG 220, for

operation in a region of ÷10 - 40°C. At working temper-

atures outside this area, synthetic oil should be used.

Recommended synthetic oil types are:

Troubleshooting:

Fault

Cause

Remedy

Abnormal noise from

the rubber blades

during operation

Incorrect adjustment of the plastic

edges

Foreign object in the separator

Adjust the plastic edges according to "Service and

maintenance"

Remove foreign object

Direction of rotation

reversed

Connection of phases reversed

Connect L1, L2 and L3 correct

Material has difficul

-

ties from falling out

of the separator, or

the suctional effect

at productional loca-

tion reduced

Worn out rubber blades

Material is piled up in lumps

Material is not removed immedi-

ately on outlet side

Material fall velocity to low

Material is supplied in to large

amount

Renew rubber blades (and possibly also plastic

edges)

Composition of material should be modified at pro

-

ductional location

Ensure sufficient emptying

Composition of material should be modified at pro

-

ductional location

Material amount should be reduced

BP

Enersyn SG-XP 220

Castrol

Alphasyn GS 220, PG 220, EP 220, Tribol

800/220, 1510/220 or Optigear Synthetic X 220

Fuchs

Renolin PG 220 or Unisyn CLP 220

Klüber

Klübersynth GH 6-220 or GEM 4-220 N

Mobil

Glygoyle 220 or SHC 630

Shell

Omala S4 WE 220 or S4 GX 220

Maintain the geared motor according to the manufac-

turer's instructions.

Separator type Oil quantity litres

RVS 5000

0,7

RVS 10000

1,8

RVS 20000

4,5

Unmounting of the ATEX

versions:

The separator should be thoroughly cleaned internally

by vaccum cleaning or the like, to avoid any dust explo-

sions in connection with the unmounting of the separa-

tor. Observe all local regulations concerning correct

recycling.

Содержание RVS 10000 S3 CR 50

Страница 38: ...38 X ...

Страница 63: ...63 ...