12

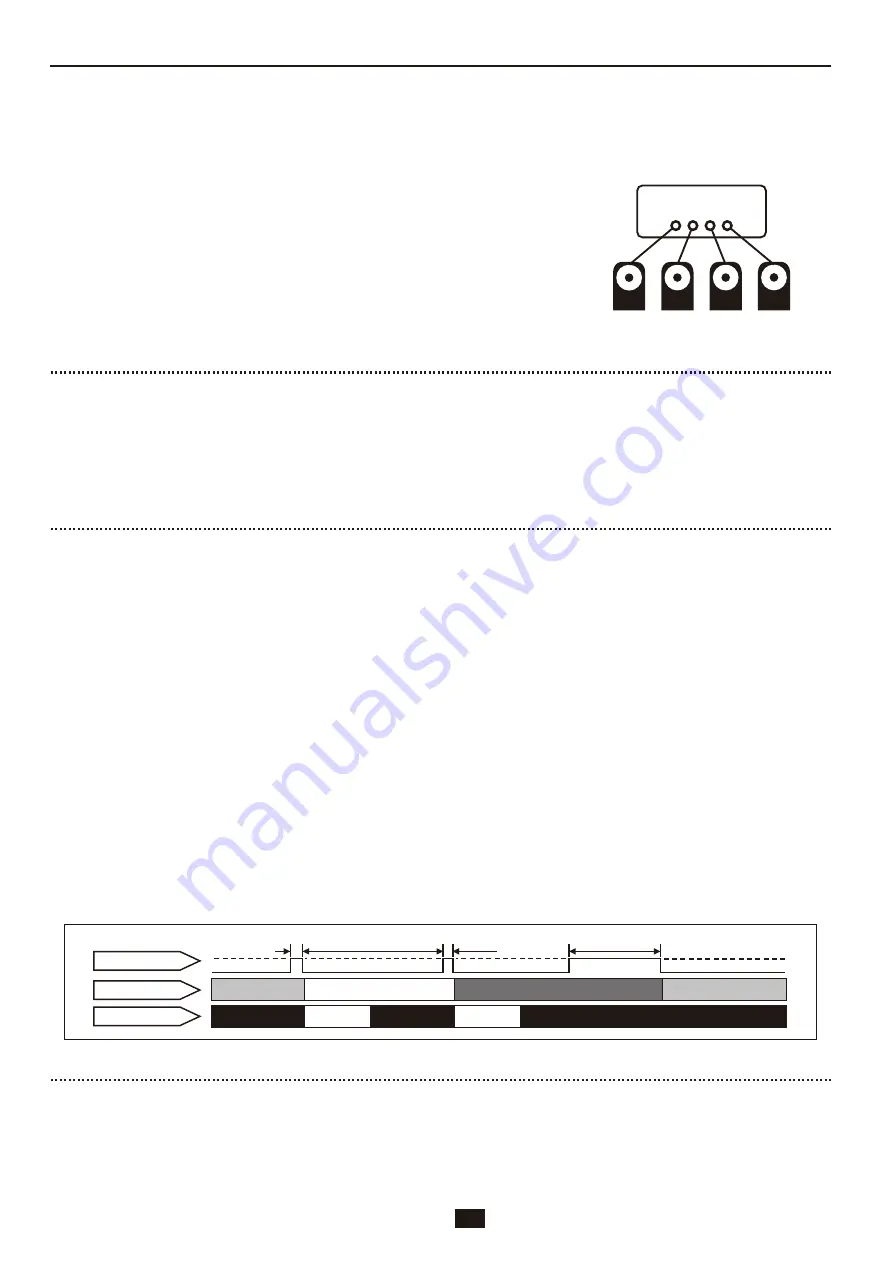

■Controlling Servos with a Control Board

Only one servo per output port may be connected when using a PWM

signal. Uncheck the Serial Signal check box.

■Control Using Programming

Please refer to When using a PWM signal in the ICS 3.5 Command

Reference to control the servos in PWM mode.

Example of how servos are

connected in PWM control

mode.

Control Board

Servos

1 2 3‥n

1 2 3 n

・

(Ch)

※Voltage drops and/or noise in the signal may cause unintentional movement during operation. Use this

product with caution.

※Using the position capture (teaching) function in conjunction with a home-made control board requires

pull-up resistor in the signal wire from the control board CPU. Furthermore, the CPU servo control board

needs to be able to change between signal input and output. Kondo control boards are compatible with the

position capture function.

Points of Caution When Using a PWM Signal

Using a PWM Signal

100〜200μsec

50μsec

700〜2300μsec

■ Diagram showing the timing of the signal and servo movement ■

■Position Command (MOVE)

The output shaft of the servo rotates in accor-

dance with the PWM input signal.

700μs (-135 ° ) to 1500μs (0 ° ) to 2300μs

(+135°)

■Power Limitation

Inputting a pulse width of 50μs will reduce the

power output of the servos. This state of limited

power output will be maintained until the servos

receive the next position command with a pulse

width between 700μs and 2300μs.

■Characteristic Change (Stretch preset change)

Inputting a pulse width of 100μs, 150μs or 200μ

s will instruct the servos to change between three

preset characteristics (SET1 ˜ SET3 stretch set-

tings) saved within the servo.

The servos will maintain the state the output shaft

was in directly before they were instructed to

change position.

Preset parameters (SET1, SET2 and SET3) can be

changed using the ICS menu. Setting 1 (SET1) will

automatically be selected when turning the servo

power on. 。

Stretch 1 (SET1) 100μs +/-10μs

Stretch 2 (SET2) 150μs +/-10μs

Stretch 3 (SET3) 200μs +/-10μs

■Position Capture (Teaching)

Inputting a pulse width of between 50μs and 200

μs will instruct the servos to output a pulse width

that indicates the current position of the servo

output shaft. This pulse output from the servos is

then read by the control board and the current posi-

tion of the servos can be ascertained.

Movement of Servos Using a PWM Signal

RCB-3HV

RCB-3J

PWM Compatible Control Boards

When operating this product using a PWM signal, position commands

can be made using general radio control signals.

Functionality can also be expanded by using other specific signals.

PWM cycle compatibility:3ms 〜 30ms

Pulse width: Normal operation 700μs to 2300μs.

Expanded function 50μs to 200μs.

※The KRS 3000 series is designed to be operated between 6.0 and 7.4 volts. Ensure the input current is within that range.

KCB-5 : 6 x PWM outputs. Teaching and characteristic change are possible depending on the programming.

(Cannot be used in conjunction with serial terminal, so separate wiring is required.)

: RCB-3HV/RCB-3J: 24 x PWM outputs. Up to 24 servos can be connected. Suitable for teaching

and changing characteristics.

Normal movement

Normal movement

Servo movement

input

signal

Hold

Input

Input

Input

Servo signal line

Output

Output

Input signal present

No input signal present

Power limitation