Manual EDU 2AE/TOP/MITO

Page 2

EDU 2AE/TOP/MITO power supply and control units are an innovative system for controlling the torque of

any MITO electric screwdriver either inline, pistol, with angle head or for automation.

EDU 2AE/TOP/MITO delivers all the advantages of precision torque control electric tools at a fraction of

the price of transdurized tools.

The state-of-the-art electronic control circuit cuts the power supply to the motor calculating the correct

torque in response to 3 parameters; voltage, frequency and current, according to the selected options.

Model

Torque (Nm)

Speed

Min

Max

MITO 15H

0,05-1,5

100

850

MITO 15L

0,05-0,5

100

850

IMPORTANT: EDU 2AE/TOP/MITO is a highly accurate unit but it is critically important to select

the correct options to ensure that proper torque is being applied. Read the menu description carefully

and in case you are unsure please contact Kolver for support information.

Turn the unit on through the on/off switch on the back panel. The unit will carry a general system check and

the words

“

waiting connection

” will appear

on the last line of the display. If the connection with the motor

control board is successful the following screen will be displayed:

K o l v e r

S . R . L .

E D U

2 A E

T O P

M I T O

V e r s i o n

1 . 0

l o a d i n g . . .

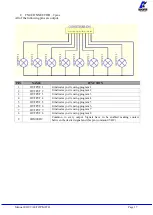

Press any key on the front panel to enter the main screen (see following picture).

M I T O 1 5

1 0 : 0 0

P R : 1

S :

0 / 0 1

T :

A :

w a i t i n g

1- Reached torque level in Nm or in.lbs

2- Program number or sequence

3- Screwdriver model

4- Clock

5- Screw count: done screws/total screws

6- Angle value in degrees (only model EDU 2AE/TOP/MITO/TA)

7- Status bar (ready,

errors, etc…)

2

1

3

4

5

6

7

Содержание EDU 2AE/TOP/MITO

Страница 22: ...Manual EDU 2AE TOP MITO Page 22 EXPLODED VIEW...