8

1058907-W2-J

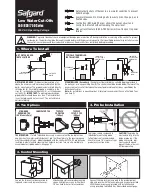

INSTALLATION

General

Installation must be carried out in accordance with these instructions and must

be conducted by designated, qualified and competent personnel.

Before commencing, make sure that the installation conditions comply with the

information given in section:

'Specifications'

. For Type 3 valves see also Installation

conditions in The TMV3 Requirements Manual.

The installation must comply with the “Water Supply (Water Fittings)

Regulations or Scottish Byelaws” or any particular regulations and practices,

specified by the local water company or water undertakers.

1.

Care must be taken during installation to prevent any risk of injury or

damage.

2.

The hole in the basin must be a minimum of 26 mm up to a maximum of 36 mm

diameter, with a basin thickness of 30 mm maximum.

3.

The Thermotap-3 should be positioned for easy access during use and

maintenance. All routine maintenance procedures can be conducted with the

Thermotap-3 body in place.

4

. Inlet pressure tappings which allow measurement of the inlet pressures to

the mixing valve under operating conditions are particularly recommended for

healthcare applications with Type 3 valves.

5.

Pipework dead-legs should be kept to a minimum. The overall length from the

hot water circuit to the discharge point should not exceed 5 m.

6.

Supply pipework layout should be arranged to minimise the effect of hydraulic

restriction or other outlet usage upon the dynamic pressures at the Thermotap-3

inlets. Recommended minimum supply line pipe diameter is 8 mm.

7.

For

Dynamic Supply Pressures

below

0.4 bar

we recommend removal of the

flow regulators to allow increased flow.

8. To eliminate pipe debris it is essential that supply pipes are thoroughly

flushed through before connection to the Thermotap-3.