ADJUSTMENTS

12

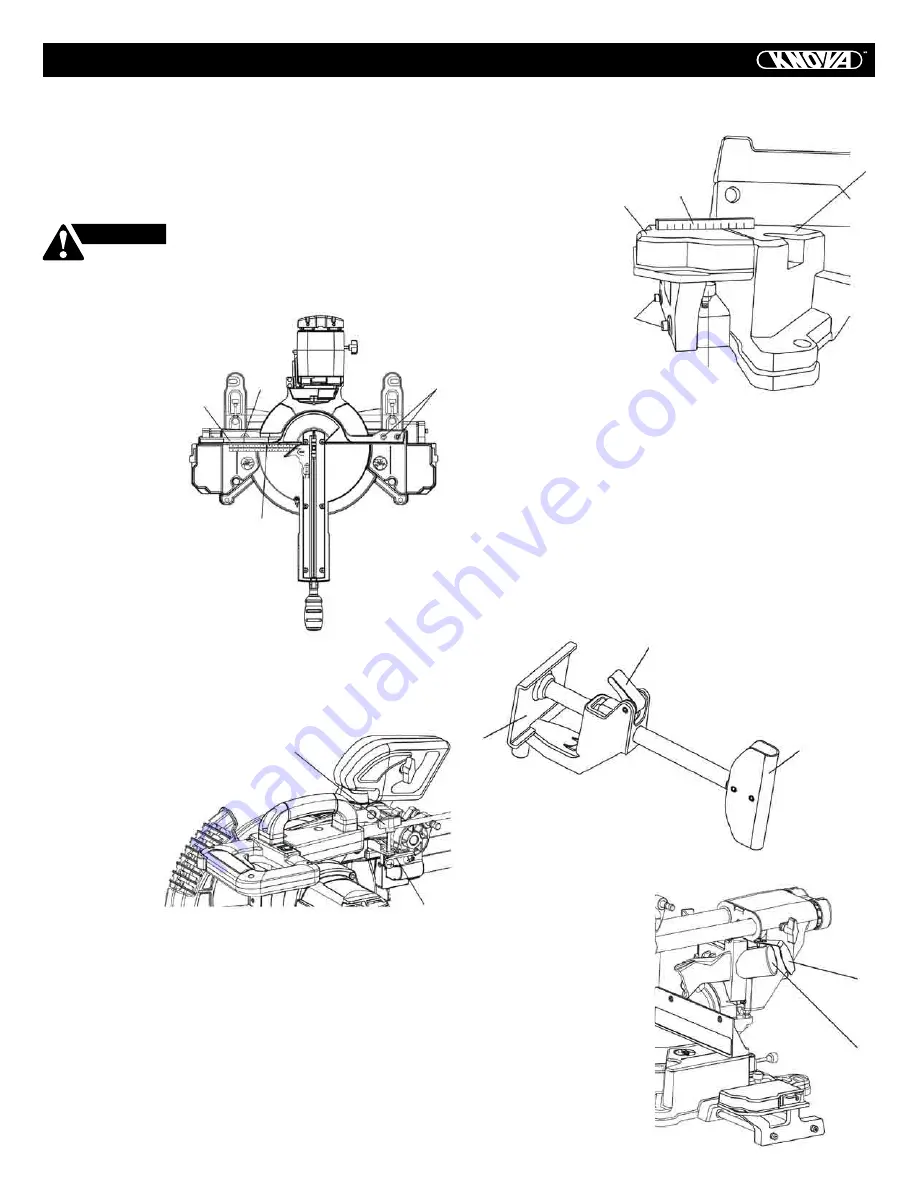

MITER SCALE INDICATOR (FIG. R)

1. Move the table to the 0° positive stop.

2. Loosen the screw (4) that holds the indicator with a

screwdriver.

3. Adjust the indicator (3) to the 0° mark and retighten screw.

ADJUSTING FENCE SQUARENESS (FIG. S)

2

WARNING

1. Loosen the three fence locking bolts (1).

2. Lower the cutting arm

and lock in position.

3. Using a square (3), lay the heel

of the square against

the blade and the

ruler against the

fence (2) as shown.

4. Adjust the fence

90° to the blade

and tighten the

four fence locking

bolts.

5. After fence has been

aligned, using a scrap

piece of wood, make a cut

at 90° then check squareness on

the piece. Readjust if necessary.

If the saw has not been used recently,

recheck blade squareness to the fence and readjust

if needed.

1

3

1

SETTING CUTTING DEPTH (FIG. T)

The depth

of cut can be preset for even and repetitive shallow cuts.

1. Adjust the cutting head down (See CUTTING HEAD

section) until the teeth of the blade are at the desired

depth.

2. While holding the upper arm in that position, turn the stop

knob (1) until it touches

the stop plate (2).

3. Recheck the blade depth by moving

the cutting head front to back

through the full

motion of a

typical cut

along the

control arm.

1

2

Fig. T

ADJUSTING CUTTING DEPTH (FIG. T)

The

maximum

depth travel of the cutting head was set at the

factory. Check to see that the blade does not extend more

than 6.4 mm below the table insert, and does not touch the

control arm throat or any part of the base or table. If the maxi

-

mum depth needs readjusting:

1. Loosen

the stop knob (1) while moving the cutting head

down until the blade extends just 6.4 mm below the table

insert.

2. Adjust the stop knob (1) to touch the stop plate (2).

3. Recheck the blade depth by moving the cutting head

front to back through the full motion of a cut along

the control arm.

ADJUSTING EXTENSION HEIGHT TO MAIN TABLE (FIG. U)

1. Tighten the two lock knobs (1) to lock the extension (2).

2. Loosen the two hex screws (3)

using a 4 mm hex wrench.

3. Place a straight

edge (4) on the

extension, across

the main table (5).

4. Adjust the extension

until it is flush with

the main table, and

then retighten

the two hex

screws (3).

5. Repeat for other

side if needed.

4

3

2

5

1

ADJUSTING THE VISE CLAMP (FIG. V)

1. Rotate the knob (1) counterclockwise to allow enough

room for the workpiece to fit between the hold plate (2)

and the sliding fence unit.

2. The clamp incorporates a quick-release lock lever (3). To

use the quick-release function, lift up the quick-release

lock lever and slide the clamp forward or backward to

the desired position.

3. When the clamp plate is located at the desired position,

flip the quick-release lock lever down to engage the

threads thereon with the threads on the clamp, and rotate

the knob clockwise to secure the workpiece within the

hold plate and the sliding fence unit.

NOTE: If intend to release

the workpiece from seccure

status, counterclockwise the

knob first before lifting up

the quick-release lock lever.

3

2

1

Fig. V

THE DUST EXHAUST

PORT (FIG. W)

1. To prevent the metal

dust from spraying out,

turn the cover plate (1)

to cover the dust

exhaust port (2) when

cutting the metal.

1

2

Fig. W

Fig. S

Fig. U

Содержание KN M-2502N

Страница 53: ...www knova com mx...