10

During inspection, it should be checked whether

•

the technical data is observed in accordance with the rating plate,

•

there are no leaks (oil, grease, water),

•

the operating noises of the bearings as well as the smooth running of the motor have not

deteriorated,

•

all mounting screws for electrical and mechanical connections are tight,

•

the connection of cable screws on the terminal box is fixed properly. If the cable screws are loose,

the strain relief (if present) should be loosened and then, the cable screw should be tightened until

the cable can no longer move. Tightening the cable screw too firmly will cause constrictions in the

cable and should absolutely be prevented. After successful tightening, the strain relief (if present)

should be refastened.

•

the alignment of the motor is within the approved tolerances during coupling operation.

•

any accumulated dust is removed.

4.2 Bearings

4.2.1 Bearings with permanent lubrication

The motor bearings with permanent lubrication are maintenance-free under normal operating

conditions for 10000 to 20000 operating hours, but not longer than 3 years.

Lubricants

see page 11.

Mixing of different grease types must be avoided!

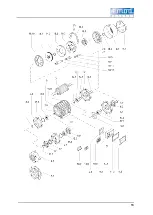

4.3 Repair

Spare parts lists and regular drawings do not contain the types and dimensions of the parts.

Therefore, the type and dimensions of the concerned parts should be determined during disassembly

and they should be marked for assembly.

4.3.1 Joint sealing

For motors with protection class IP56 or higher (see rating plate), the part joints between the motor

housing and the bearing plates should be sealed with a suitable, non-hardening sealing mass.

5

Spare parts

For spare parts orders, the motor type and motor number (details can be found on the rating plate)

must always be specified in addition to the exact part designation.

With the exception of standardised commercially available and equivalent parts, e.g. ball bearings,

only original parts may be used.

This applies in particular for seals and terminals.

6

Final decommissioning (disassembly, recycling,

disposal)

Always disassemble motors in such a way that environmentally-friendly recycling and disposal of the

motor components is possible.

When recycling and disposing of the disassembled motor components, always observe the legal

regulations and provisions applicable at the time of the final decommissioning!

Содержание N630.12

Страница 65: ...13...

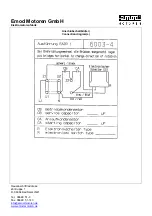

Страница 67: ...15 9 Documents provided Circuit diagram...

Страница 69: ......

Страница 70: ...1 Operating manual for single phase motors Frame size 56 112 EHB EARZ Issue 1 0 11 19 All rights reserved...

Страница 82: ...13...

Страница 84: ...15 9 Documents provided Circuit diagram...

Страница 87: ......

Страница 88: ...KNF worldwide You can find our local KNF partners at www knf com...