22

04

05

▶

08

06

07

▶

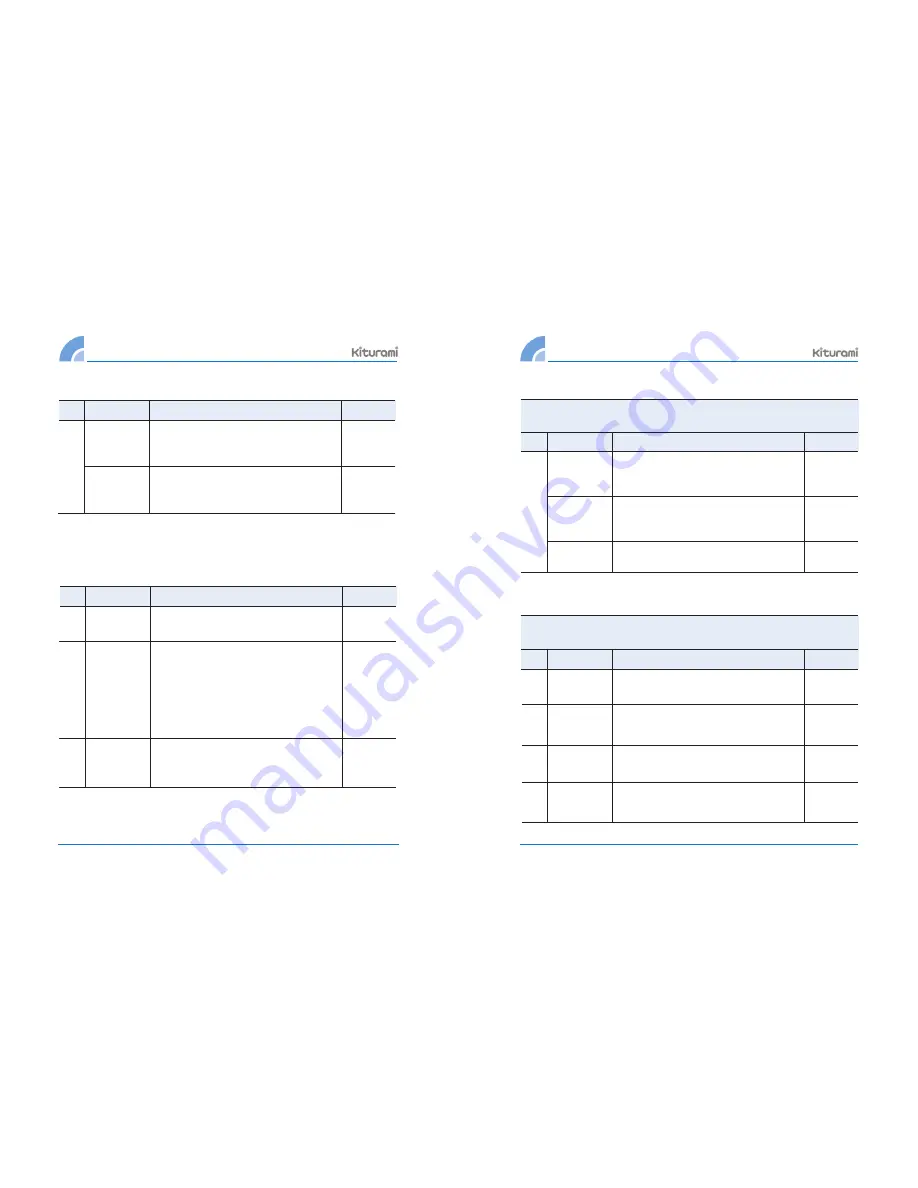

Troubleshooting

Trouble: Disconnection of temperature sensor and overheat sensor

No

Failure

Troubleshooting

Remarks

No

Failure

Troubleshooting

Remarks

Trouble: Defective transmission/reception

1. Water temp.

sensor

disconnected

2. Overheat

sensor

disconnected

1. Blower RPM

not detected

2. Low limit,

High limit

3. Defective

transmission/

reception

①

Check the water temperature sensor for

correct connection.

②

Check the wiring for damage.

③

Replace the temperature sensor.

①

Check the overheat sensor for correct

connection.

②

Check the wiring for damage.

③

Replace the temperature sensor.

①

Check the wiring of the blower for

damage.

②

Replace the blower.

①

The RPM of the blower is too low or too high due to foreign

materials caught on the blower housing

②

Too high RPM of the blower or the exhaust may be caused by

strong wind when the flue is installed in the wind pressure zone

Contact the installation shop about changing the location of the

flue.

③

Remove condensate from the curved part of the flue, if any.

④

Contact your distributor or the after-sales service center.

①

Defective transmission/reception of the room controller and

the main controller: Ignition travel turned off

②

If the problem persists for more than ten minutes, Error 08

has occurred, and the power LED blinks.

③

Replace the room controller (automatic recovery).

Disassembled

part of burner

23

98

▶

96

▶

Troubleshooting

Trouble: Overheat error

Trouble: Triggering of the overheat sensor (bimetal) due to

counter-flow of flame

No

Failure

Troubleshooting

Remarks

No

Failure

Troubleshooting

Remarks

1) Symptom: Detecting water temperature higher than 93

℃

by the water temperature sensor/detecting

temperature higher than 92

℃

by the overheat sensor

2) Recovery: Automatic recovery upon water temperature lower than 88

℃

/overheat lower than 87

℃

1) Step 1: Temperature at the water temperature sensor lower than 10

℃

- Released when the circulation

pump operates at temperature higher than 12

℃

2) Step 2: Temperature at the water temperature sensor lower than 7

℃

- The circulation pump and the burner

start operation.

1. The circulation

pump

inoperable

2. The CH valve kept

lock to cause rapid

elevation of temp

erature

3. Controller

failure

Installing

detachable

pump

Installing the

boiler in the

boiler room

①

Check the circulation pump circuit of the coil.

The measurement result for a resistance of ‘0’

indicates normal operation; ‘infinite’ indicates a

circuit of the coil. Replace the circulation pump.

①

Check whether the distributor valve is locked;

if it is, open the locked valve.

①

The feed motor continues operating even

when the fuel feed is in the halting mode.

②

Replace the controller.

1. Fuel clogged

2. No Tee installed

on the flue causing

head wind

3. Fire tube

clogged

4. Poor air-tightness

of the fuel feed line

①

Clean the flue.

①

Install a Tee on the flue to prevent head wind.

①

Clean the fire tube of the boiler.

①

Poor air-tightness of the hoses and the pipes used

for feeding the fuel to the burner causes overheat

ing. Disassemble the band, check the air-tightness,

and reassemble the band.

Содержание KRP-20A

Страница 14: ...26 Memo 27 Memo ...

Страница 15: ...30 Memo ...