32

5.5.2

For inspections where load suspension parts of the hoist are disassembled, a load test per ANSI/ASME

B30.16 must be performed on the hoist after it is re-assembled and prior to its return to service.

Table 5-3

Periodic Inspection

Requirements of frequent inspection.

Evidence of loose bolts, nuts, or rivets.

Evidence of worn, corroded, cracked, or distorted parts such as load blocks, suspension housing,

chain attachments, clevises, yokes, suspension bolts, shafts, gears, bearings and pins.

Evidence of damage to hook retaining nuts or collars and pins, and welds or rivets used to secure

the retaining members.

Evidence of damage or excessive wear of load and idler sheaves.

Top Hook/Yoke Gap excessive wear

Evidence of excessive wear on motor vanes or on load brake.

Evidence of damage of supporting structure or trolley, if used.

Function labels on pendant control stations for legibility.

Warning label properly attached to the hoist and legible (see Section 1.2).

End connections of load chain, including presence of chain down stopper.

5.6

Occasionally Used Hoists

5.6.1

Hoists that are used infrequently shall be inspected as follows prior to placing in service:

◼

Hoist Idle More Than 1 Month, Less Than 1 Year: Inspect per FREQUENT Inspection criteria of

Section 5.3 above.

◼

Hoist Idle More Than 1 Year: Inspect per PERIODIC Inspection criteria of Section 5.5 above.

5.7

Inspection Records

5.7.1

Dated inspection reports and records should be maintained at time intervals corresponding to those

that apply for the hoist’s PERIODIC interval per Section 5.2.5. These records should be stored where

they are available to personnel involved with the inspection, maintenance, or operation of the hoist.

5.7.2

A long range chain inspection program should be established and should include records of

examination of chains removed from service so a relationship can be established between visual

observation and actual condition of the chain.

5.8

Inspection Methods and Criteria

5.8.1

This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection. In accordance with ANSI/ASME

B30.16, these inspections are not intended to involve disassembly of the hoist. Rather, disassembly for

further inspection would be required if frequent or periodic inspection results so indicate. Such

disassembly and further inspection should only be performed by a qualified person trained in the

disassembly and re-assembly of the hoist.

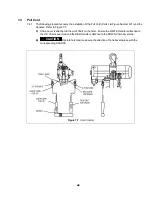

Содержание TCL Series

Страница 43: ...43 Figure 7 4 Single Fall Chain Connections Figure 7 5 Double Fall Chain Connections ...

Страница 52: ...10 1 Motor Valve Body and Controls 52 Figure 10 1 Motor Valve Body and Controls ...

Страница 55: ...55 This Page Intentionally Left Blank ...

Страница 56: ...10 2 Brake Gears and Load Suspension Components 56 Figure 10 2 Brake Gears and Load Suspension Components ...

Страница 61: ...61 NOTES ...

Страница 62: ...62 NOTES ...

Страница 63: ...63 NOTES ...