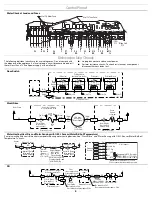

2

Wi

rin

g

D

ia

gr

am

Sc

he

m

at

ic

s

ho

w

n

w

ith

d

oo

r

sw

itc

h

an

d

a

ll

othe

r

no

rm

al

ly

o

p

en

co

ntac

ts

open.

*De

no

tes

en

er

gy

-e

ffic

ie

nt

co

mpon

ents. Do not substitute.

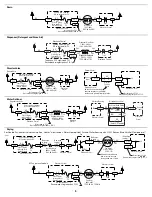

Most used test points on

PC board for multimeter

checks.

N

WH

BK

Ferrite

(1 Loop)

BK

WH

Heater

Element

Thermostat

(Hi-Limit)

BU/R

BU-R

N.C.

Micro Pin

K1

HTR-N

Relay

K3

HTR-L

Relay

P4

P4-4

P4-3

P4-2

P4-1

BK

WH

K4

Sense

Motor

Relay

Optional

P5

F9

Fuse

P5-2

P5-1

LB

LB

L1

N

3 2

1

1 - PH Sync

Wash

Motor

Pump

Drain

Motor

1

3

3

3

3

3

1

1

1

Overfill

(Float)

Switch

FillValve*

Softener

Regen Valve

(Not All

Models)

Diverter

Motor

1

3

1

3

1

3

1

3

1

3

1

3

1

2

1

3

1

2

3

4

3

1

3

1

3

1

2

4

5

6

(Spare)

(Spare)

Future

Future

Vent Wax

Motor

Fan Motor

Optional

Flow

Meter

39K

Softener

Salt Sensor

(Closed When

Empty)

(Not All Models)

Diverter

Position

Switch Contact

(Closed During

Transitions)

(Spare)

Future

O.W.I*

(NTC, Foam, & Turbidity Sensor)

BR

BR

BR

BR

BR

BR

BU

BU

BU

BU

RD

RD

RD

RD

V

V

V V

BR

BR

BR

BR

13V

VCC

REF

(+8V)

(N)

(-5V)

7

P

6

P

P8

P9

P10

P11

P12

P13

3

Door Open Detection

P2

1 2

3 4

13V

Pilot L1

Test

Pad For

All

Triac

Loads

Fan Load

(Current)

Sense

Analog

Input

Digital

Input

Analog

Input

NTC

Input

Opt

Sig

Foam

Drive

Turbo

Drive

13V

VCC

Wide

Data

13V

Beeper

REF

VCC

Wide Data

P1A P1B

LED

Displays

14-pin

Mechanical

Push-Button

Boards

20-pin

Active

Overlays

19-pin

ZIF

1

3

2

4

5

6

7

Blac

k Str

ipe On Connector

Red

Str

ipe On Connector

P6-1

P6-3

P6-4

P6-6

P6-7

P6-9

P7-1

P7-3

P7-4

P7-6

P8-1

P8-3

P8-4

P8-6

P9-1

P9-3

P9-5 P9-6

P10-1

P10-3

P10-5

P10-4

Micro Pin

Micro Pin

Micro Pin

K2

F8

Fuse

Or

5

1

Dispenser

Wax Motor

P13-1

P13-2

P13-3

P13-4

LCD UI

4-pin

Pilot

Relay

W2

P1

1-

3 R

D

P11-3 RD

P11-2 RD

P11-4 RD

P11-5 RD

P1

1-

6 R

D

P12-1

YL

P12-2

YL

P12-3

YL

P12-4

YL

P12-5

YL

P12-6

YL

Dispenser

Solenoid

Door Switch

On some models

Temporary

Connection Port

for Development

Tools (& future

service tools)

P1A and P1B

User Interface

Connector Options

Capacitive Touch

Keyboards 4-pin

P1-VCC

P4-REF

Electronic Control* CCU1

PC Board 190.28 x 81.01 mm

2-sided FR4

Power Supply

Level 1-3W

Level 2-4.4W

Level 3-7.4W

Motor Sense circuit

is different for

High vs Low Power motors

Return Line 13 Volt relay coils go through Door Switch

AC Input

Overfull/Leak Detection

(and Pilot Relay detection)

Load (current) Sense for drain, vent and all other triac loads on Pilot

In Factory programming port

(on top surface of PCB)

(Depopulate in production; use pads)

CR-

1

BU

/W

H

BU

/R

D

1

2

3

4

P1C

L1

1

2

3

1

2

3

1

2

3

1

2

3

4

Light

Light

Light

To Connector P13

Light In tub

(on some models)

GY

GY

3

1

Fan Motor

or