6

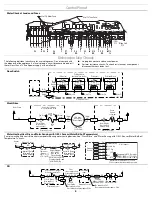

Service Diagnostics with Error Codes

Entry sequence: Press any 3 keys in the sequence 1-2-3-1-2-3-1-2-3 with no

more than 1 second between key presses.

NOTE:

Some models have replaced the “CLEAN” LED with “COMPLETE.”

If no error, “Clean” LED stays on for 5 seconds or display shows “F-” or “E-”.

NOTE:

Once error codes are extracted, refer to the “Service Error Codes” table

to diagnose and correctly resolve the root cause condition.

Service Error Codes

Example: 6-1 means “Inlet Water” function, “Low/No Water” problem.

DISPLAY TEST - ALL LEDS ON

INTERVAL 26

ERROR 1 - MOST RECENT

INTERVAL 25

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5 sec.

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 sec.

ERROR 2

INTERVAL 24

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5 sec.

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 sec.

ERROR 3

INTERVAL 23

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5 sec.

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 sec.

ERROR 4 - OLDEST

INTERVAL 22

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5

seconds

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 second

10 seconds pause

Hi Temp LED will be On

INTERVAL 21

Press Hi Temp key to clear errors.

Hi Temp LED will blink twice to indicate errors have been

cleared.

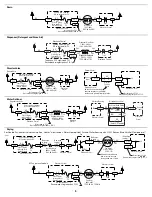

Service Diagnostics Cycle

INTERVAL 20-3

Turns on loads and checks sensors.

SERVICE CYCLE ERROR 1

INTERVAL 2

A tone will play when service

error code 1 is displayed

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5 sec.

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 sec.

SERVICE CYCLE ERROR 2

INTERVAL 1

SHOW

FUNCTION

CODE

PAUSE

SHOW

PROBLEM

CODE

PAUSE Repeat 3

times

unless

advanced

by Start

key.

Count Clean

LED flashes

2 sec.

Count Clean

LED flashes

5 sec.

OR ON DISPLAY MODELS

Read “F#”

on Display

0.5 sec.

Read “E#”

on Display

1 sec.

Function

Code

Problem

Code

Causes

What to Check

1-Control 1-

Pilot Stuck

On

Control detected

K2 pilot relay stuck

closed.

1. Unplug dishwasher or disconnect

power.

2. Check all loads on K2 pilot relay

for shorts.

3. Replace control and all shorted

components.

2-

Control

Software

Issue

1. Damaged or

corrupted memory

or control board.

Incompatible

software

components

inside micro.

1. Unplug dishwasher or disconnect

power.

2. Replace control board.

2. All LED’s

are On.

1. Unplug dishwasher or disconnect

power.

2. Replace UI (for numeric display

models only).

2-

User

Interface

1-

Stuck Key

Control detected

stuck key(s) in

keypad or keypad

connection.

NOTE:

If any keys

are stuck, the

stuck key(s) will be

ignored and an

error recorded to

service history but

no alert to

customer.

Check responsiveness of each

key.

1. If some keys do not respond,

then:

- Unplug dishwasher or

disconnect power.

- Disassemble door and

disconnect keypad connection

from control or LCD display

module.

- Verify all other connections to

control are made.

- Reassemble door, but do not

close door.

- Plug in dishwasher or reconnect

power.

- Wait at least 7 seconds for

control to power up completely.

- Close dishwasher door and

monitor control response:

A. If control is OK (no longer

sees stuck keys with keypad

unplugged), it will respond by

turning on the drain motor for

2 minutes. Replace keypad

and console.