KD GEMINI – INSTALLATION/OPERATION MANUAL

KD Gemini

May-06

6

DRAFT CONTROL

Use approved draft control supplied for 5” pipe. Use two draft

controls on strong draft chimneys. Set specified draft pressure to

-0.04” wc.

Not applicable to Direct Vent installations

.

3.6 ASSEMBLE & INSTALL BURNER

ASSEMBLE

Check burner model is correct for furnace rating required.

BURNER

Assemble as per burner manufacturer’s instructions.

SET END CONE

Riello – Set turbulator as per furnace operating decal.

Beckett – See Burner Manufactures Instructions.

SELECT NOZZLE

Select oil input, nozzle required and burner configuration as shown

on furnace operating decal.

INSTALL NOZZLE

Install selected nozzle, check for clean seating and tighten in

nozzle adaptor.

CHECK

See burner manufacturer’s instructions for correct setting.

ELECTRODES

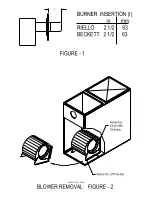

INSERTION

See “GENERAL SPECIFICATIONS” or diagram (Figure – 1).

LENGTH

MOUNT BURNER

Tighten top nut first so burner tips down slightly. The burner is

always installed in an upright position by four nuts.

PUMP BY-PASS

For one pipe system factory setting (no plug).

PLUG

WIRING

Refer to wiring diagram or wiring decal for correct burner

connections.

Riello series burners use the Riello LT-1 thermostat

relay or Honeywell R8038 relay.

THERMOSTAT

Connect thermostat terminals.

DO NOT

start the oil burner until installation is complete and all cleanout covers are

secured in place.

3.7 CHANGING NOZZLE

NOZZLE

If a new nozzle of a different size is installed, change the heating

CHANGE

blower speed according to the “BURNER SPECIFICATIONS” or

operating decal.