– 11 –

▼

▼ ▼

▼▼

▼▼

▼

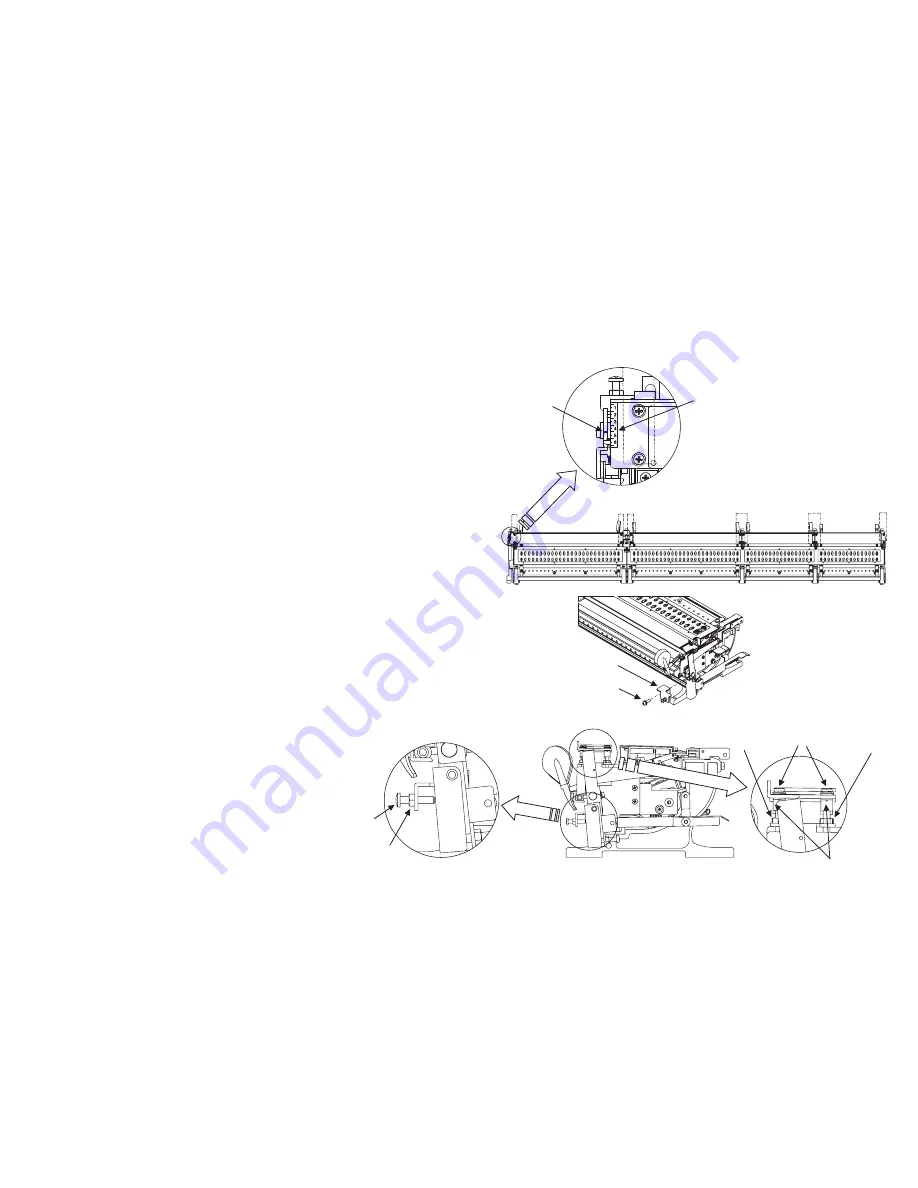

Adjust screw A

Lock nut A

Lock nut B

Lock nut B

Adjust screw B

(Upper)

Adjust screw B

(Lower)

Indicator

(Guideline)

Adjusting

point

Adjusting

point

Adjusting

point

Adjusting

point

Adjusting

point

Read the number on the scale

This indicates “4.5”.

(Longer scale line means 0.5)

Figure 2

Figure 3

Figure 4

Screw for hammer rail

(attached here)

Rail positioning fitting

[Work Procedure] - Adjusting the stop rail height per section -

In the GP, the distance between the keybed and the string undersurfaces may vary depending on the

areas of the piano.

In the GP-ATX, it is possible to adjust the stop rail height per section to follow the variation of this

distance, and make sure that the muting happens at the 4 mm point of let-off.

This procedure should be implemented when the adjustment per section is needed if the muting works

only partially.

【B-8】

Using the jig, adjust by 4 mm the let-off of the keys at both ends of each section (8 keys in total).

* If the 4 mm jig is not available, adjust it by 4 mm by visual judgment using the 3 mm jig

instead.

【B-9】

Switch to the Silent Mode, and write down the value of the scale located at the bass side of the

stop rail, as shown in Figure 2.

【B-10】

Attach the rail positioning fitting on the action as shown in Figure 3.

* The rail positioning fitting is fixed with a screw at the treble side of the rear chambranle

(threshold, Kamachi).

* One screw for the hammer rail is attached at the bass side end of the action.

【B-11】

Loosen the lock nut A (Figure 4) and rotate the adjust screw A so that the scale indicator at the

bass side of the stop rail points to the value read in 【B-9】. Then tighten the lock nut A to fasten

the stop rail.

* By doing this, the height of the stop rail across the board becomes equal to that of when it was

in the piano.

【B-12】

Adjust the height of the stop rail aligning it to the let-off position of both ends of each section.

* There are eight areas to adjust as shown in Figure 2.

* Loosen the lock nut B (Figure 4) and adjust the height using the adjust screw B (Upper).

Rotate clockwise : Lower Rotate counterclockwise : Lift

* Adjust both forward and backward ends to make it parallel to the hammer shank.

Then rotate the adjust screw B (Upper) about one time per turn.

※ Especially for counterclockwise rotation, the adjust screw B (Upper) could drop off from the

adjust screw B (Lower).

If that happens, remove the adjust screw B (Upper) once and apply a slight coat of instant

glue on the screw hole of the adjust screw B (Lower) then tighten the adjust screw B (Upper).

* After completing the adjustment, tighten the lock nut B without changing the adjust position

of the adjust screw B (Lower).

【B-13】

Align the let-off of the remaining keys to the stop rail.

* Move the hammer shank at the let-off position as close as possible to the stop rail.

【B-14】

Remove the rail positioning fitting and fasten the stop rail at the original

position on the rear chambranle (threshold).

【B-15】

Put the action back into the piano and re-install keyslip, keyblock and

fallboard.

【B-16】

Check the muting state.

* Criteria for judging

・ Hit strongly each section of the keyboard five times in

a row with three fingers of your dominant hand, and

make sure that the hammer does not strike the string.

・ If the string was hit during the above, repeat the

procedure from 【B-8】 for re-adjusting.