Page 43

Copyright © 2012 Kato Engineering, Inc. All rights reserved

NOTICE: Make sure all components are

clean before assembly.

NOTICE: Torque fasteners to the values

specifi ed in Table 3 unless otherwise speci-

fi ed.

NOTICE: Do not pound on the rectifi er or

armature windings. Component damage

may result.

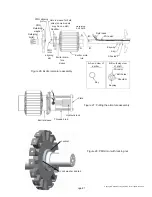

Assembly

Bearing installation (done prior to installing the rotor)

1. Heat the bearing to 220º F (104

o

C) - 250º F (121

o

C) in a clean oven

or with an induction heater.

2. Start the heated bearing on the shaft. Then use a fi ber or soft metal

tube to tap the bearing into place.

3. Ensuring that pressure is applied only to the bearing inner ring,

press the bearing onto the shaft until the inner ring seats against the

bearing shoulder on the shaft. Assemble the rest of the generator after

the bearing has cooled.

Overall assembly

1. Float in the rotor until the rotor and stator laminations line up.

Position the rotor such that a full pole face is at the bottom.

2. Install the endbrackets. Support the rotor during installation. Put an

corrosion inhibitor on the bare mating surfaces to prevent rust.

3. Install the exciter armature and optional PMG as described below.

4. Install the covers.

5. Install the coupling or drive plates.

6. Reconnect the load leads and exciter leads.

Exciter armature and PMG installation (see Figure 26)

1. Clean the shaft and inside of the exciter sleeve.

2. Place the key in the slot in the shaft.

3. Lay the generator fi eld wires fl at in the wireway with the wire ends

protruding past the end of the shaft.

4. Position the exciter armature assembly in line with the shaft, and turn

the assembly to the position where the keyway in the exciter sleeve is

in line with the key in the generator shaft.

5. With hand force, push the exciter armature assembly over the shaft,

so the end of the sleeve is against the shoulder on the shaft. When

it is part of the way onto the shaft, start the fi eld lead wires through

the wire hole or slot in the exciter sleeve. It may be necessary to tap

lightly on the exciter sleeve in order to move the assembly over the

key. Use a fi ber or rubber mallet. If installation is still a problem, use

a heat gun to expand the exciter sleeve.