kaivac

cleaning

systems

TM

P a g e ǀ

2 2

1-800-287-1136

Customer/Technical Support

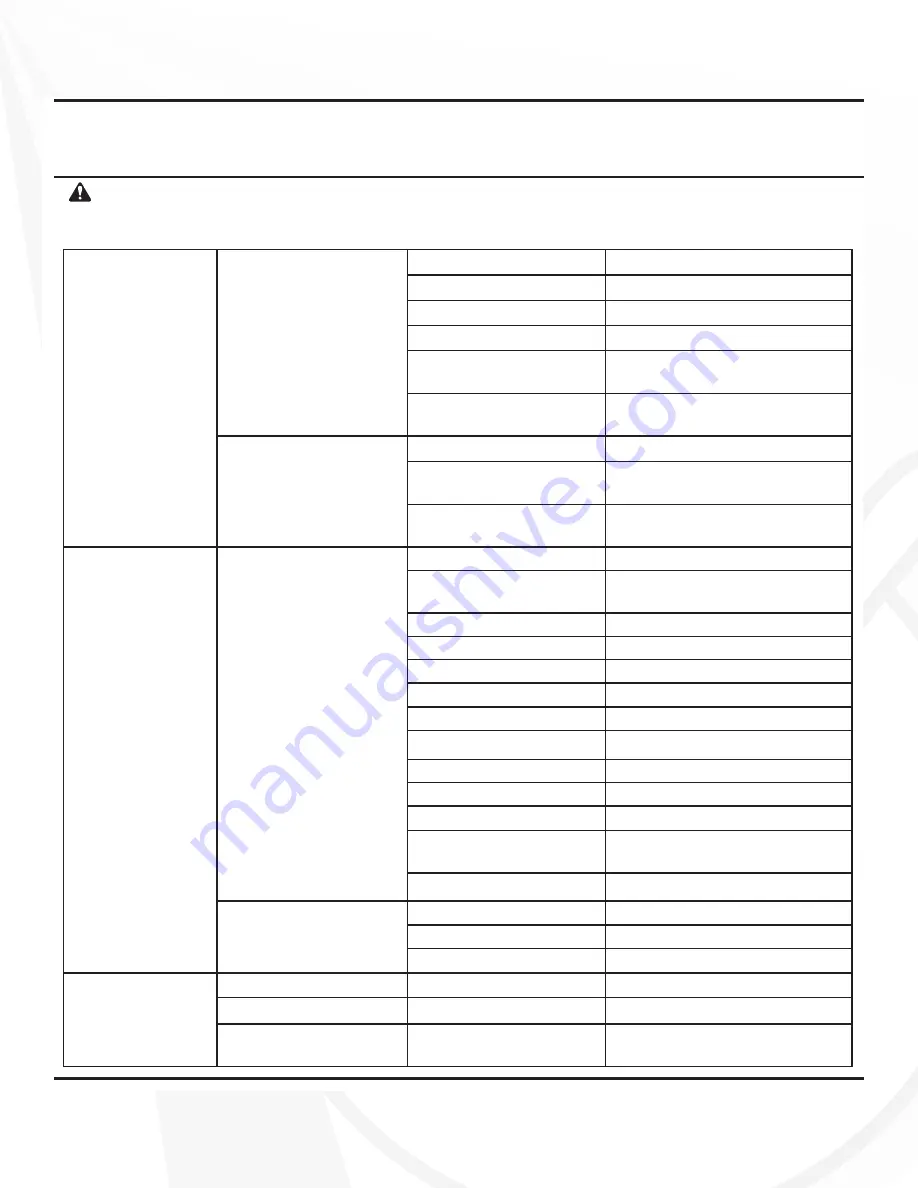

4.1 t

RoUbLeshooting

4.0 Troubleshooting and Upkeep

Electrical

No Power to pump or

vac motor

Machine not plugged in

Plug machine in

Switch not “on”

Check switches for “on”

GFCI tripped

Test and reset GFCI

Building circuit overloaded

Check and reset circuit

Switch wires loose

Disconnect power and check for

loose wire

Connections loose

Disconnect power and check for

loose wire under panel

Electrical burning smell

Vac motor brushes worn

Remove vac motor and repair

Vac motor hung up

Release pressure on hose and jog

vac switch, or replace

Pump motor hung up

Release pressure on hose and jog

pump switch, or replace

Vacuum System

No/Weak vacuum

Vac tank full

Empty vac tank

Squeegee blades or wheels

worn

Replace wheels or blades and

check periodically

Float shutoff screen dirty

Spray off float screen to clean

Float ball stuck

Tap float and release/clean

Damaged hose

Cut and repair/replace

Dump hose plug missing

Contact dealer and replace

Access lid not right

Tighten lid hand tight

Vacuum hose plugged

Flush hose to remove debris

Too much liquid in vac hose Allow air in when vacuuming

Vac hose still wrapped

Unwrap vac hose fully

Exhaust plugged

Remove HEPA filter and clean

Leak in vac tank

If repairable, clean and dry affected

area and seal with silicone

HEPA filter clogged

Remove HEPA filter and clean

Moisture from exhaust

Vac tank full

Dump vac tank

Float shutoff missing

Replace

Excessive foam in vac tank

Use defoamer

Blow Dry System

No air flow

Hose disconnected

Reconnect hose

Moisture from exhaust

Water in blow hose

Dry blow line

Suction, not blow action

Vacuum hose connected to

vac tank

Reconnect to vac motor exhaust

hose

CAUTION

:

Always unplug machine before lifting electric cover assembly.

AREA

PROBLEM

POSSIBLE CAUSE

SOLUTION

High Pressure

System

No water from pump

or low pressure

Out of water

Fill water tank

Gun nozzle plugged

Remove orifice with Allen wrench

and clean

Air in pump (vapor lock)

Use power prime technique

Gun orifice missing

Replace orifice

Water tank filter plugged

Clean tank and filter

In-line bowl filter plugged

Remove filter cover and clean

Bowl filter lid loose

Gently tighten bowl cover

Pressure hose damaged

Repair or replace

Quick disconnect leaking

Tighten or replace

Injector plugged

Remove safety cap from chemical

and blow small amounts of

compressed air into line

Pulse hose damaged

Repair or replace

Regulator failed

Replace

Hose kinked

Unkink and check for damage

Seals in pump need replaced

Remove and replace seals

Bad fan pattern or

pinpoint pattern on

gun

Debris in nozzle

Remove orifice with Allen wrench

and clean

Orifice damaged

Remove and replace

Chemical Injection

System

No chemical flow

Out of chemical

Refill chemical

Safety cap not secure

Check safety cap/tighten

Chemical valve “off”

Check on/off valve

Safety cap plugged

Replace cap

Spray gun in wrong mode

Make sure gun nozzle is pulled out

away from gun chemical mode

Metering tip plugged

Check metering tip for clog

Injector plugged

Remove safety cap from chemical and blow

small amounts of compressed air into line

Air entering system

Check for air entering system

around chemical lines or injector

Injector installed backwards

If fluttering or pulsing sound can be

heard while spraying or when machine

is running, it is possible that your injec-

tor is in backwards. Remove; reinstall.

Kink in chemical line

Replace chemical line

Содержание 1250

Страница 2: ......

Страница 38: ...Don t just clean it Kaivac it kaivac cleaning systemsTM TM TM ...