3-4

Note:

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be re-

ferred to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the meas-

uring instruments as described in the following electrical ad-

justment procedures. After this, proceed to the repair, re-

placement and/or adjustment. If the required measuring in-

struments are not available in the field, do not change the

adjustment parts (variable resistor, etc.) carelessly.

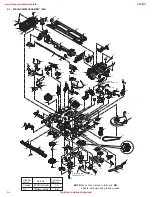

Fig. 3-3-1-1a Switching point

3.3.1

Servo circuit

3.3.1.1 Switching point

3.3

Electrical adjustment

V.sync

Trigger point

Switching point

V. rate

Signal

(A1)

• Stairstep signal

(A2)

• Alignment tape (LP, stairstep, PAL) [MHPE-L]

(A3)

• Alignment tape (EP, stairstep, NTSC) [MHP-L]

Mode

(B)

• PB

• TBC:OFF

Equipment

(C)

• Oscilloscope

Measuring point

(D1)

• VIDEO OUT terminal (75

Ø

terminated)

(D2)

• TP106 (PB. FM)

External trigger

(E)

• TP111 (D.FF)

Adjustment part

(F)

• Jig RCU: Code “5A”

(F1)

• Jig RCU: Code “51” or “52”

Specified value

(G)

• 7.5 ±0.5 H

(G)

• 8.0 ±0.5 H (PAL)

• 7.5 ±0.5 H (NTSC)

Adjustment tool

(H)

• Jig RCU [PTU94023B]

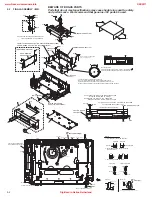

3.2.4 A/C head phase (X-value)

Signal

(A1)

•

Alignment tape(SP, stairstep, PAL) [MHPE]

(A2)

•

Alignment tape(LP, stairstep, PAL) [MHPE-L]

Mode

(B)

•

PB

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

TP106 (PB. FM)

External trigger

(E)

•

TP111 (D.FF)

Adjustment part

(F)

•

A/C head base [Mechanism assembly]

Specified value

(G)

•

Maximum V.PB FM waveform

Adjustment tool

(H)

•

Roller driver [PTU94002]

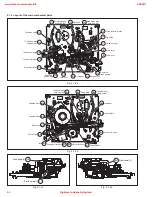

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Loosen the screws (4) and (5), then set the Roller driver

to the innermost projected part of the A/C head. (See Fig.

3-2-4a.)

(5) Rotate the roller driver so that the A/C head comes clos-

est to the capstan. From there, move the A/C head back

gradually toward the drum until the point where the FM

waveform is maximized for the second time, and then

tighten the screws (4) and (5) temporarily.

(6) Play an alignment tape (A2) and set to the manual-track-

ing mode.

(7) Fine-adjust A/C head base position to maximize the FM

waveform, and then tighten the screws (4) and (5) firmly.

(8) Play alignment tapes (A1) and (A2) and confirm that the

FM waveforms are maximized when the tracking is at the

center position.

Head base

Roller driver

To the capstan

To the drum

Toward the capstan

Toward the drum

Screw (5)

Screw (4)

A/C head

Fig. 3-2-4a

Fig. 3-2-4b

Alignment tape

[SP, stairstep]

played with the

SP head

Alignment tape

[EP(LP), stairstep]

played with the

EP(LP) head

Drum side

Control head position

Capstan side

X-value adjustment point

Maximum

Waveform output

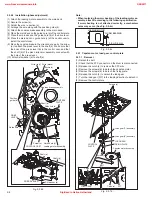

[For the model without TBC function]

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D. FF (E) to observe the

VIDEO OUT waveform and V. PB FM waveform at the meas-

uring points (D1) and (D2).

(3) Set the VCR to the manual tracking mode.

(4) Adjust tracking so that the V. PB FM waveform becomes

maximum.

(5) Set the VCR to the Auto adjust mode by transmitting the code

(F) from the Jig RCU. When the VCR enters the stop mode,

the adjustment is completed.

(6) If the VCR enters the eject mode, repeat steps (1) to (5) again.

(7) Play back the alignment tape (A2) again, confirm that the

switching point is the specified value (G).

[For the model equipped with TBC function]

Steps (1) to (4) are the same as previous steps (1) to (4).

(5) Transmit the code (F1) from the Jig RCU to adjust so that the

trigger point of the VIDEO OUT waveform is changed from

the trailing edge of the V. sync signal becomes the specified

value (G1).

(6) Set the VCR to the stop mode or eject mode.

(7) Play back the signal (A1) of the alignment tape (A3).

(8) Repeat steps (2) to (6).

www.freeservicemanuals.info

3/28/2017

Digitized in Heiloo Netherland