1-9

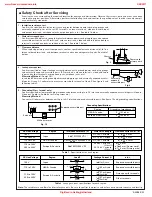

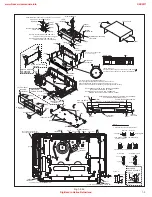

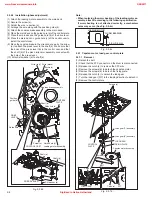

1.4 Service position

This unit has been designed so that the Mechanism and Main

board assemblies can be removed together from the chassis

assembly. Before diagnosing or servicing the circuit boards,

take out the major parts from the chassis assembly.

1.4.1

How to set the “Service position”

(1) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the Mecha-

nism assembly.

(2) Remove the screws that fix the Mechanism assembly to the

Chassis assembly. If any other screws are used to fix the

boards, remove them also.

(3) Remove the combined Mechanism and Main board assem-

blies.

(4) If any other major parts are used, remove them also.

(5) Connect the wires and connectors of the major parts that

have been removed in steps (1) to (4). (Refer to Fig. 1-2-2d.)

(6) Place the combined Mechanism, Main board and other

board assemblies upside down.

(7) Insert the power cord plug into the power outlet and then

proceed with the diagnostics and servicing of the board as-

sembly.

Notes:

•

Before inserting the power cord plug into the power out-

let, make sure that none of the electrical parts are able to

short-circuit between the workbench and the board as-

sembly.

•

For the disassembly procedure of the major parts and de-

tails of the precautions to be taken, see “1.2 Removing

the major parts”.

•

If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, be sure

to remove them (including wires connected to the major

parts) first before performing step (2).

•

When carrying out diagnosis and repair of the Main board

assembly in the “Service position”, be sure to ground both

the Main board and Mechanism assemblies. If they are im-

properly grounded, there may be noise on the playback

picture or FDP counter display may move even when the

mechanism is kept in an inoperative status.

•

In order to diagnose the playback or recording of the cas-

sette tape, set the Mechanism assembly to the required

mode before placing it upside down. If the mechanism

mode is changed (including ejection) while it is in an up-

side down position the tape inside may be damaged.

•

For some models, the mechanism and board assemblies

are attached by connectors only. When carrying out a di-

agnosis or repair of the boards in the “Service position”,

make sure that the connectors are not disconnected.

Fig. 1-4-1a

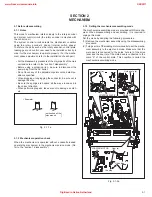

1.6 Mechanism service mode

This model has a unique function to enter the mechanism into

every operation mode without loading of any cassette tape. This

function is called the “Mechanism service mode”.

1.6.1

How to set the “Mechanism service mode”

(1) Set the VCR to the Jig RCU mode (the mode in which codes

from the Jig RCU can be received).

(2) Transmit the code “E5” from the Jig RCU.

(3) Release the lug of the Cassette holder and then slide the

Cassette holder toward the direction where the Cassette

holder is loaded by manually.

(4) The cassette holder lowers and, when the loading has com-

pleted, the mechanism enters the desired mode.

When the VCR is set to the Mechanism service mode, the

symbols (“Timer”) in the FDP (LED) are blinked.

1.6.2

How to exit from the "Mechanism service mode"

(1) Unplug the power cord plug from the power outlet.

1.5 Jig RCU mode

This unit uses the following two modes for receiving remote

control codes.

1) User RCU mode : Ordinary mode for use by the user.

2) Jig RCU mode

: Mode for use in production and servic-

ing.

When using the Jig RCU, it is required to set the VCR to the

Jig RCU mode (the mode in which codes from the Jig RCU

can be received). As both of the above two modes are stored

in the EEPROM, it is required to set the VCR back to the User

RCU mode each time that an adjustment is made or to check

that the necessary operations have been completed. These

modes can be set by the operations described below.

1.5.1

Setting the Jig RCU mode

(1) Unplug the power cord plug from the power outlet.

(2) Press and hold the “REC” and “PAUSE” buttons on the VCR

simultaneously, while plugging the power cord plug into the

power outlet.

When the VCR is set to the Jig RCU mode, the symbols

( “ : ” ) in the time display of the FDP are turned off.

1.5.2

Setting the User RCU mode

(1) Turn off the power.

(2) Press the “REC” and “PAUSE” buttons of the VCR simulta-

neously. Alternatively, transmit the code “80” from the Jig

RCU.

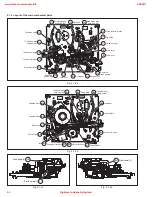

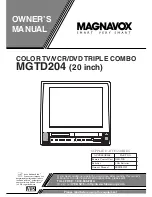

CP4001

CN7001

CN511

CN1601

CN916

CP3001

TP106

PB.FM

TP2253

A.PB.FM

TP4001

CTL.P

TP111

D.FF

Main board

assembly

S/P converter

board assembly

C3025

Timer clock

VR2251

REC AGC ADJ

VR1603

BURST

VR1601

R-Y

VR1602

B-Y

ONLY USED FOR

HR-S6955MS,

HR-S7955MS

To Adv. jog board assembly

To Front S jack board assembly

www.freeservicemanuals.info

3/28/2017

Digitized in Heiloo Netherland