5

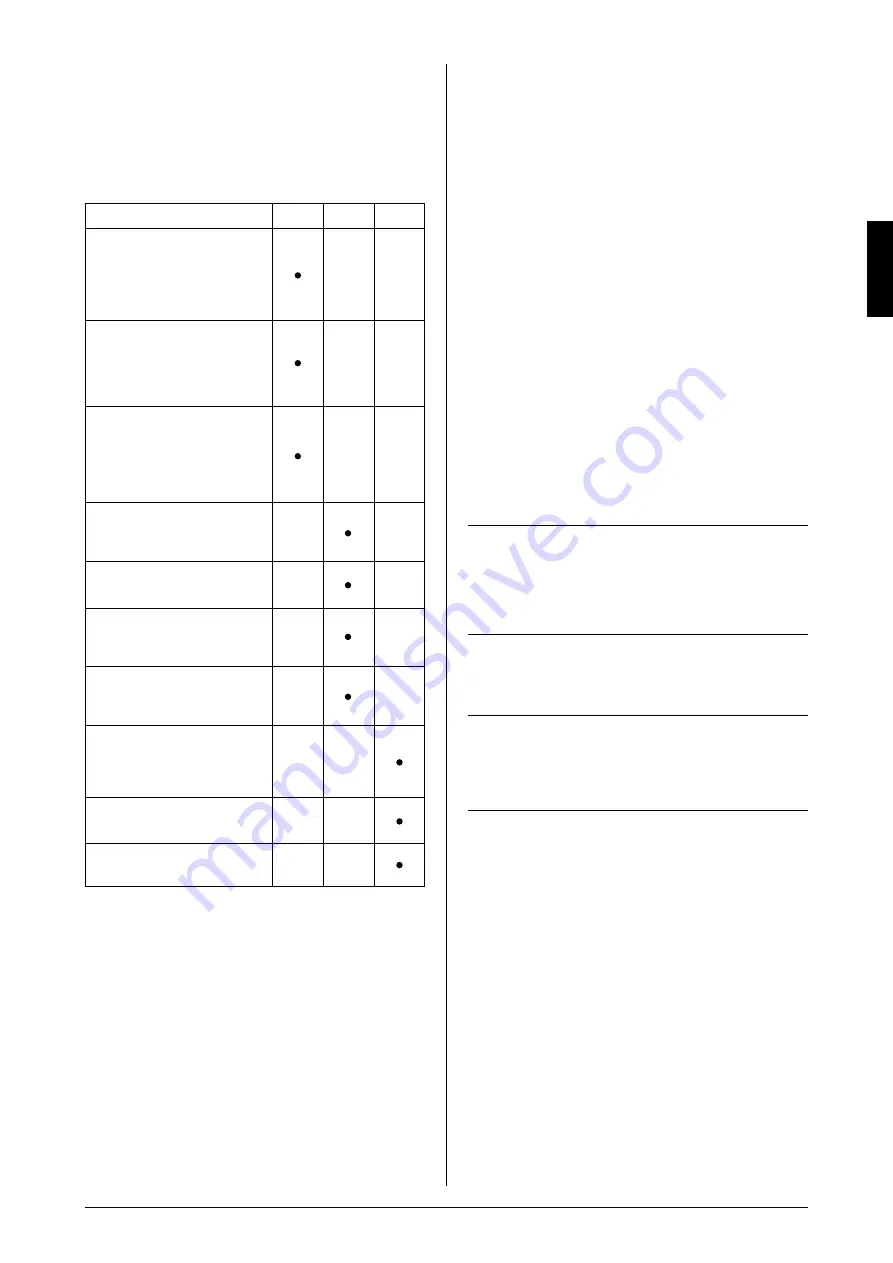

Preventive compressor maintenance

An hour meter is installed on all "BD" and "PD" models.

Observe after 1 month how many hours the compressor has

performed in order to obtain an impression of the maintenance

intervals which are every 2000 working hours. However, at

least once every year.

Weekly

Monthly Annually

If compressor is not fitted with dryer,

drain condensate from air receiver

(at a pressure of max. 2 bar/0 psi).

If equipped with autodrain, this will

take place automatically, however,

drain bottle has to be emptied.

If compressor is fitted with outlet

filter, check and empty for water

by pressing the black button in the

bottom. If fitted with autodrain, this

will take place automatically.

Make sure that the fan at the top

of the cover works. Fan starts at a

motor temperature of 2°C/89°F and

runs continuously until temperature

has fallen, although compressor

does not work.

Check compressor, air tubes and

equipment for leaks, and check the

pumping time.

Inspect and replace intake filter, if

necessary.

Clean the compressor with a soft,

damp cloth. Dust and dirt prevent

cooling.

Check dryer function according to

instructions in the "Adsorption Dryer

Manual".

Check the Oring in the nonreturn

valve and replace if necessary.

Note! Empty receiver of air before

dismounting.

Check filter and filter elements for

optimum efficiency.

Test the safety valve by gently pulling

the ring with pressure in the receiver.

Replace the air intake filters after each 2000 working hours

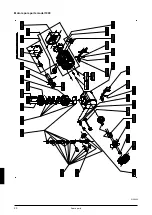

1. Switch off current.

2. Lift off the upper part of the cabinet (is locked with screws).

Be careful not to unplug the cable for the fan (this only

applies to model „P“) (fig. 5).

. Pull out the filters by means of inserting a screwdriver below

the rubber part. The new filters can then be pressed into

place (fig. 6).

Compressors with adsorption dryer:

1. Test that the automatic dryer/filter works satisfactorily

by opening the manual control drain cock, which has an

internal tube leading to the bottom of the air receiver. If

water comes out, the dryer needs to be serviced. (See

"Adsorption Dryer Manual").

2. In order to avoid pressure loss due to saturated filter

element, the pre and after filters are equipped with a pop

up indicator. When the filter element needs replacement,

the indicator turns red instead of green. Under normal

conditions the filter element must be replaced after

approx. 4000 working hours. If the environment is very

contaminated, intervals for changing filter element may be

2000 working hours. See "Adsorption Dryer Manual" for

further information.

. After 2000 to 4000 working hours dependent on the working

conditions or when desiccant in inspection glass changes

color, the desiccant in the dryer system must be replaced,

see "Adsorption Dryer Manual".

Check the pumping time

The pumping time indicates the condition of the compressor

provided that there

are no leaks in the system where the compressed air may leak.

Test the compressor as follows:

1. Empty the air receiver of compressed air (the pressure

gauge shows 0 bar).

2. Close the outlet on the air receiver and check that the drain

cock is closed.

. Start the compressor and note how long it takes until it

switches off.

Make sure that the pressure in the air receiver is 8 bar/

120 psi as deviations may indicate the wrong results (see

technical details).

Important!

Always test the compressor when cold as the time

indicated refers to the pumping time of a cold

compressor. The pumping time of a warm compressor

is much longer and consequently, the result would be

misleading.

Fault finding and repair

Important!

Switch off and isolate from electrical supply before

removing any parts from the compressor.

Empty air receiver of air before dismantling any parts

of compressor unit’s pressure system.

1. Compressor does not start (no sound):

a) No power from mains. Check fuses and plug.

b) Breakage or loose joints in electrical connections.

c) Pressure in the air receiver is too high for activation

of the pressure switch. The pressure switch makes

circuit only when pressure has dropped to preset start

pressure. Empty receiver.

d) Capacitor defective.

2. Compressor does not start, makes a buzzing sound

followed by clicking noise (cannot start against high

pressure):

a) Leaky nonreturn valve. Remove the flexible pressure

pipe and clean to find out whether air leaks from the

valve. If so, clean or replace.

3. Compressor works, but pressure does not increase in

tank (or increases too slowly):

a) Intake filter clogged. Replace.

b) Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water. Pressure drop is not to exceed 1 bar

per hour.

Operating manual

GB

Содержание 1000 motor

Страница 2: ......

Страница 11: ...11 10 4 A B 6 B A 6 8 90 120 psi 50 15 8 120 psi 15 14 2 30 psi 32 89 F BD PD 2000 RU...

Страница 20: ...20 Motor spare parts model 1000 0100400 Spare parts...

Страница 21: ...21 Motor spare parts model 2000 0200300 Spare parts...

Страница 22: ...22 0200600 Spare parts model 2000 40B Spare parts...

Страница 23: ...23 Spare parts model 2000 40BD2 0200610 Spare parts...

Страница 24: ...24 0200620 Spare parts model 2000 40P Spare parts...

Страница 25: ...25 0200630 Spare parts model 2000 40PD2 Spare parts...

Страница 26: ...26 Spare parts model 4000 40B 0400200 Spare parts...

Страница 27: ...27 Spare parts model 4000 40BD3 0400210 Spare parts...