JUDO i-soft

11

Installation

4.2

Mounting the softener without

a bypass valve

–

Firstly flush the pipe with the newly

installed rotary flange (JQE).

–

Then block off the water again (at the

main water tap or blocking valve)

and remove the assembly cover of the

built-in rotary flange.

The connection flange of the softener is

covered by a white protector cap. This pro-

tector cap is secured by two cylinder screws

M6x130 and two threaded bolts M6x137

with nuts.

Prior to removing the protector cap, the two

threaded bolts M6x137 with nuts have to be

removed and replaced with the provided

cylinder screws M6x130.

ATTENTION

Do not grasp into the connection flange

of the device after removing the white

protector cap (danger of high level pres-

sure)!

–

Loosen all four cylinder screws M6x130,

but don’t remove them (bayonet fixture)!

–

Remove the white protector cap.

The section of the profiled flange gasket

must point towards the built-in rotary flange.

Failure to observe this can lead to leaks and

water escaping. This can in turn cause water

damage to the house and its installations.

–

Lift up the softener and swivel it through

approx. 30° in an anti-clockwise direction.

–

Position it on the built-in rotary flange so

that the screw heads pass through the

bayonet fixing drill holes (see fig. 7 I).

–

Swivel the softener through approx. 30°

back in a clockwise direction.

–

Tightly fasten the four cylinder screws

M6x130 (see fig. 7 II).

After assembling the softener unscrew the

wall support so far that it rests against the

softener casing and the softener hangs

vertically to the wall.

4.3

Mounting the bypass valve

(accessories)

When assembling a bypass valve between

the built-in rotary flange and and the softe-

ner an additional bypass piping becomes

superfluous to requirements.

–

Firstly flush the pipe with the newly

installed rotary flange (JQE).

–

Then block off the water again (at the

main water tap or block-off valve) and

remove the assembly cover of the built-

in rotary flange.

–

Connect the bypass valve on the flange

side with the cast in letter “R” (pipe

flange) to the built-in rotary flange by

engaging the bayonet fitting (see fig. 8).

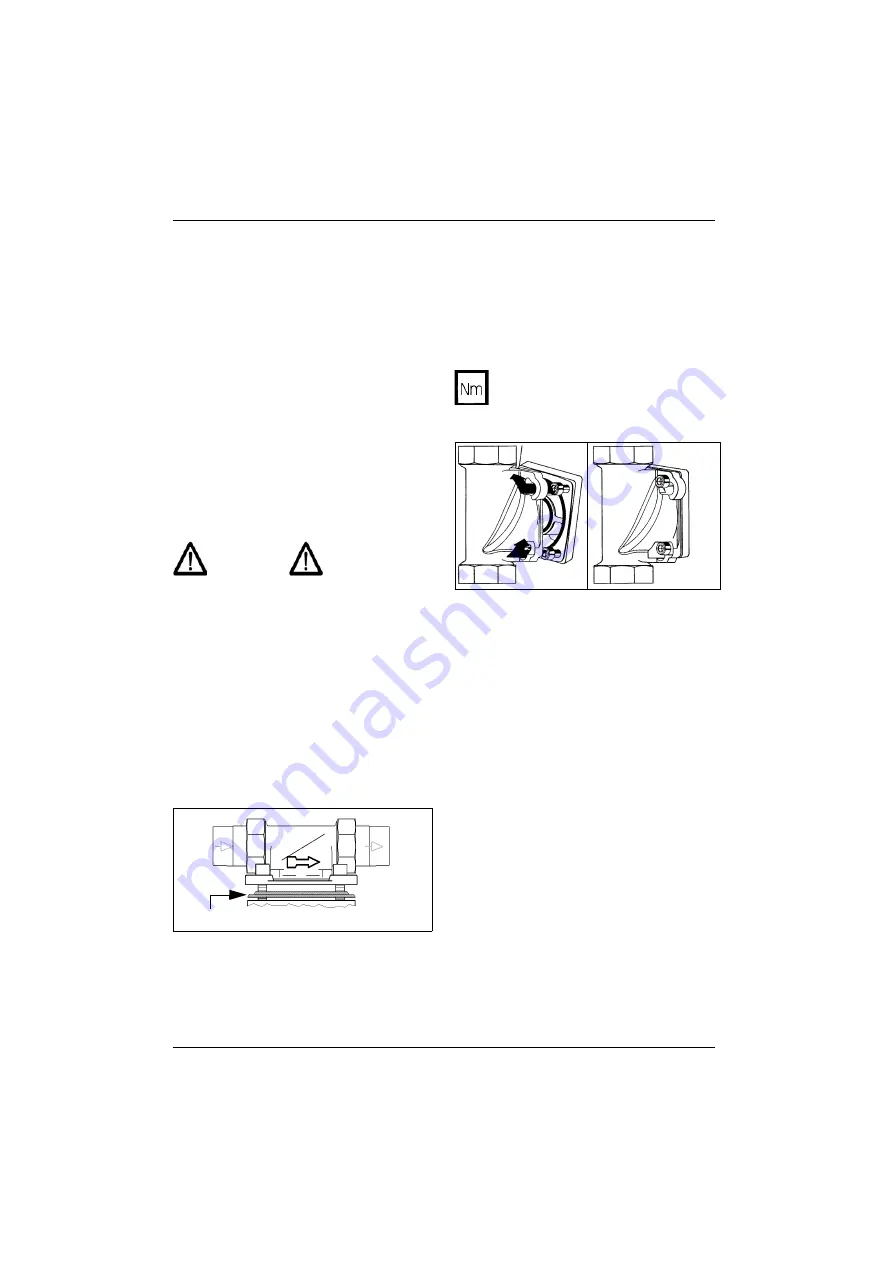

Fig. 6:

Profiled flange gasket

profiled flange gasket

Select the torque (approx. 4 Nm) so

that the gasket closes and the

softener is not damaged or strained!

Fig. 7:

Built-in rotary flange with bayonet fixture

I

II

Содержание i-soft

Страница 3: ...JUDO i soft 3...

Страница 29: ...JUDO i soft 29 Data sheet Fig 19 Electrical circuit with failure signal relay...