17

130112_Rev 2 GF 160 DV 2/22

8. Gas Supply Connection

Route the gas supply line to the flex line behind the Utility

Cover at the rear leg.

The gas supply line should be 3/8” npt with a 1/2” diameter

supply, or the appropriate size to provide sufficient gas

pressure to the valve regardless of the input setting.

The use of Flexible Gas Appliance Connectors is

acceptable in many areas in the U.S. However, Canadian

methods vary depending on local code.

ALL INSTALLATIONS MUST COMPLY WITH LOCAL

CODE OR IN THE ABSENCE OF LOCAL CODE,

MUST COMPLY WITH THE MOST RECENT EDITION

OF THE NATIONAL FUEL GAS CODE ANSI Z223.1/

NFPA 54 OR CAN-B149.

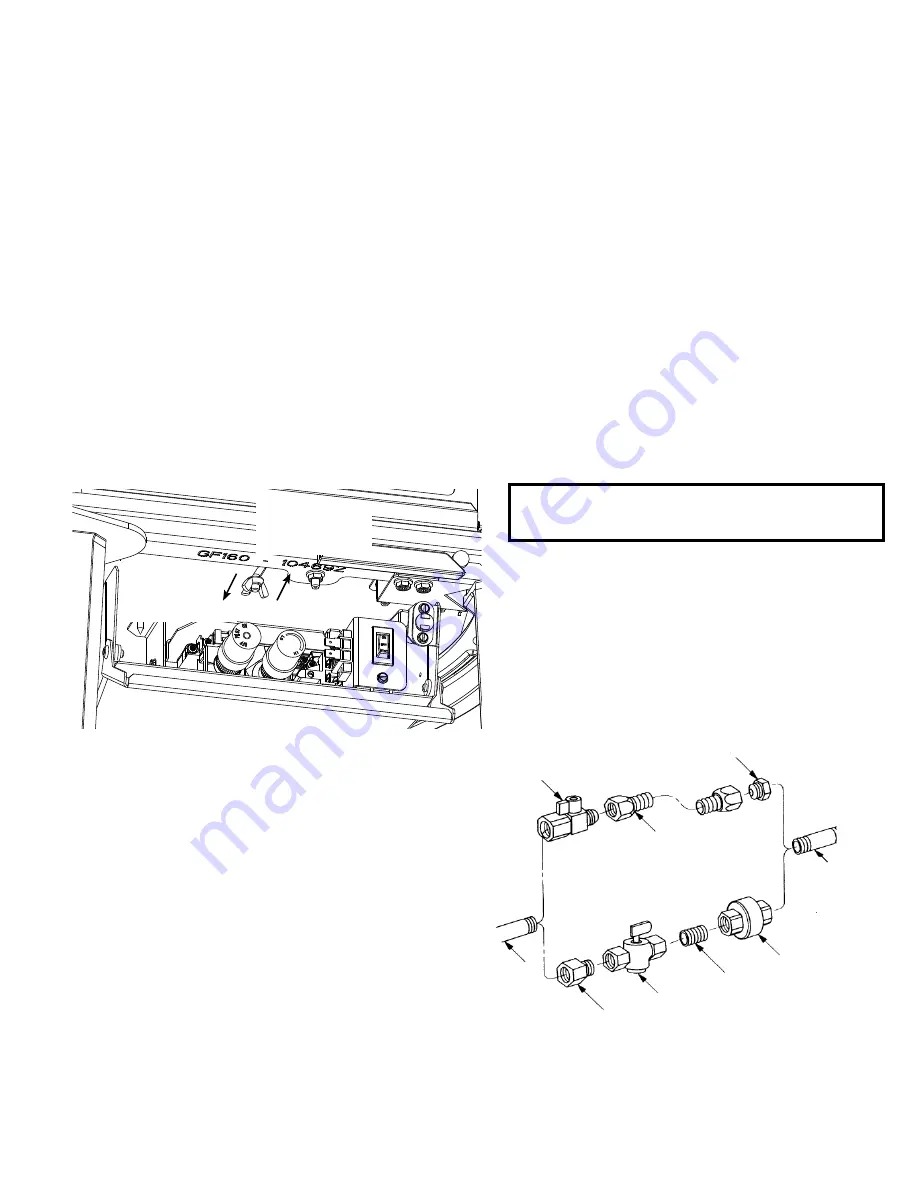

All codes require a gas shut-off valve (gas cock) and union,

to be installed in the supply line, and in the same room as

the appliance. This allows for the disconnection of the stove

for servicing and maintenance. See fig.

8.1.

A T-HANDLE GAS COCK IS REQUIRED IN

MASSACHUSETTS TO COMPLY WITH CODE

248CMR.

Secure all joints tightly using appropriate tools and sealing

compounds.

For propane units be sure to use compounds

that are propane resistant.

Turn on gas supply and test for

gas leaks at all joints.

Figure 8.1. Gas supply line connection alternatives.

Fuel Conversion, cont’d.

16. NATURAL GAS ONLY: Adjust the Air Shutter. Fig.

7. 10

The factory setting for NG is 1/16” open. Adjustment may be

necessary to provide the best flame picture depending upon the

specific vent configuration.

• Start with the shutter set open to 1/16”.

• Push the shutter stem back (to the rear) to restrict air.

• Pull the shutter stem forward (toward yourself) to open the

shutter and add oxygen to the fuel mix.

With some experimentation, you will find the shutter position

that works best for that particular installation.

• Run the stove at least 15 minutes to let the burner settle-in

before making further adjustments in very small increments

(1/16” - 1/8”)

Figure 7.10.

Pull the shutter forward to increase primary air.

Push it back to restrict air.

CLOSE -

Restrict oxygen

OPEN -

Increase oxygen