FRICK

®

QUANTUM

™

HD VILTER

®

RETROFIT

INSTALLATION INSTRUCTIONS

090.040-I02 (AUG 2014)

page 7

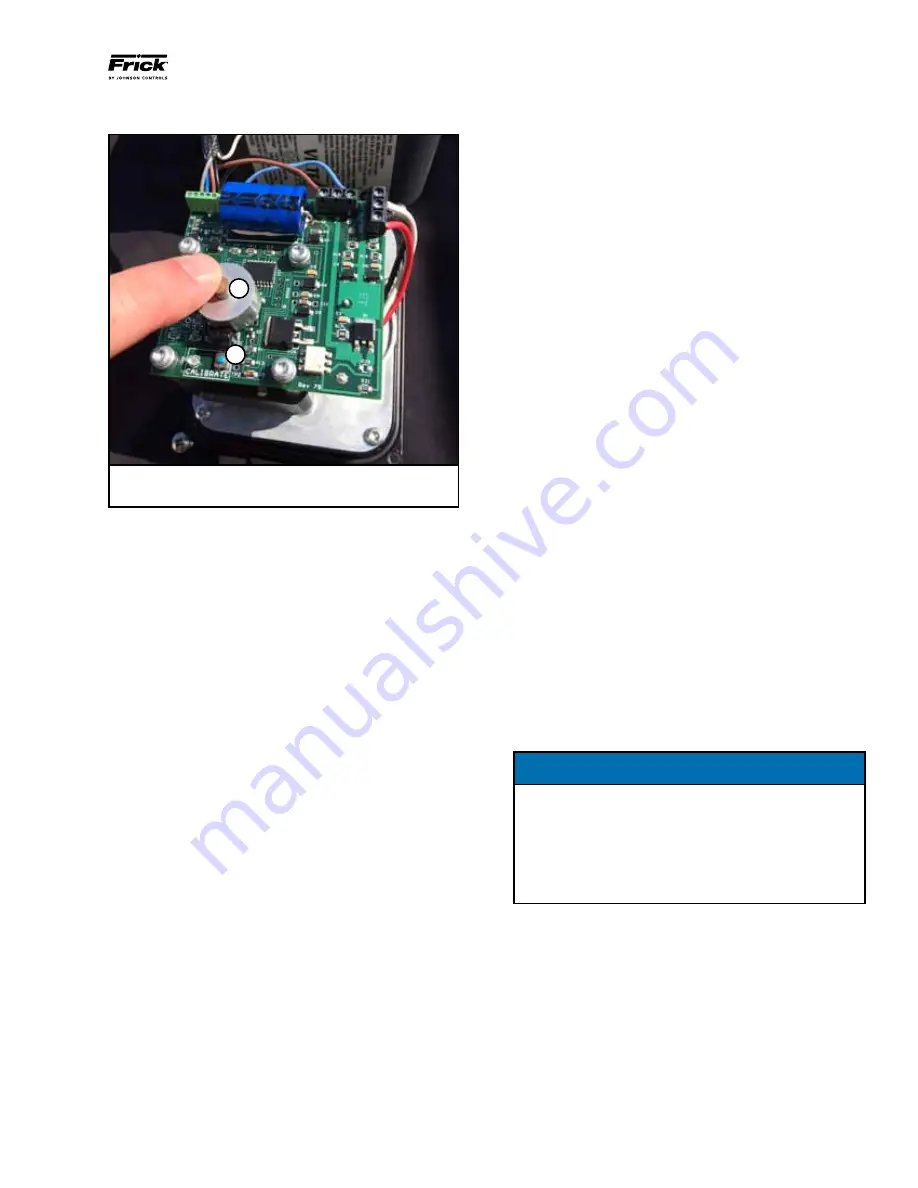

A

B

A. Photo Chopper

B. Calibration Button & LED

Figure 4. Actuator Control Board

Start with the Capacity Slide actuator

1. Press the blue calibration button on the actuator control

board. The red LED will begin flashing at a fast rate.

2. Touch the Unload Capacity button on the

QUANTUM

™

HD

calibration page to drive the capacity slide to its minimum

physical position. Watching the photo-chopper on the

actuator control board it will be evident when the capac-

ity slide is at the physical stop as the photo chopper will

suddenly slow and stop.

3. Quickly touch the Unload Capacity button to stop sending

the unload signal to the actuator.

4. Press down on the photo-chopper to relieve the tension

5. Touch the Load Capacity button and then again with a 1

second differential to move the capacity slide just off it's

minimum position and relief any stress on the command

shaft.

6. Touch the blue calibration button on the actuator. Once

the red LED starts flashing at a slower rate touch the Set

Low Capacity button on the Quantum HD calibration page.

7. Touch the Load Capacity button to drive the capacity slide

to it's physical maximum position. This will be complete

when the photo-chopper suddenly slows and stops.

Quickly touch the Load Capacity button to stop sending

the load signal to the actuator. Press down on the photo-

chopper to relief the tension.

8. Touch the Unload Capacity button and then again with a 1

second differential to move the capacity slide just off it's

maximum position and relief any stress on the command

shaft.

9. Press the blue calibration once more. The red LED should

stop flashing indicating that calibration of the actuator

is complete. Touch the Set High Capacity button on the

QUANTUM

™

HD

calibration screen to complete the calibra-

tion of the capacity slide.

Calibrate the Volume Slide actuator

1. Press the blue calibration button on the actuator control

board. The red LED will begin flashing at a fast rate.

2. Touch the Decrease Volume button on the

QUANTUM

™

HD

calibration page to drive the volume slide to it's minimum

physical position. Watching the photo-chopper on the

actuator control board it will be evident when the volume

slide is at the physical stop as the photo chopper will

suddenly slow and stop.

3. Quickly touch the Decrease Volume button to stop sending

the decrease signal to the actuator.

4. Press down on the photo-chopper to relieve the tension.

5. Touch the Increase Volume button and then again with a

1 second differential to move the volume slide just off it's

minimum position and relief any stress on the command

shaft.

6. Touch the blue calibration button on the actuator. Once

the red LED starts flashing at a slower rate touch the Set

Low Volume button on the

QUANTUM

™

HD

calibration

page.

7. Touch the Increase Volume button to drive the volume

slide to it's physical maximum position. This will be

complete when the photo-chopper suddenly slows and

stops. Quickly touch the Increase Volume button to stop

sending the increase signal to the actuator. Press down

on the photo-chopper to relief the tension.

8. Touch the Decrease Volume button and then again with a

1 second differential to move the volume slide just off it's

maximum position and relief any stress on the command

shaft.

9. Press the Blue calibration once more. The red LED should

stop flashing indicating that calibration of the actuator

is complete. Touch the Set High Volume button on the

QUANTUM

™

HD

calibration screen to complete the calibra-

tion of the Volume slide.

NOTICE

The capacity and volume slides are prevented from

physically hitting their mechanical/physical stops after

calibration is complete.

To do this, the software clips the range of these

devices at each end by 2% of the bit count when the

calibrate high and calibrate low end buttons are

pushed on the capacity/volume calibration page.

For additional sensors not provided with the retrofit kit, refer

to the OEM instructions regarding the sensor power require-

ment, signal type, signal range, and calibration process.

This completes the

QUANTUM

™

HD

retrofit instructions.