IDC INDUCED DRAFT EVAPORATIVE CONDENSERS

INSTALLATION - OPERATION - MAINTENANCE

S140-500 IOM (FEB 08)

Page 4

1.5 Safety

Requirements

IDC unit installation, operation, and maintenance – involves

heavy rotating machinery operating at high speed and high

voltage. Normal operations and maintenance procedures

may require working at elevations, enclosed space entry,

or use of hand and power tools. With these considerations,

safety must be the top priority in all activities with this evapo-

rative cooling product.

Imeco recommends that every client analyze and develop

an installation-specifi c safety regime that takes into account

such variables as specifi c site/system features, personnel

qualifi cations, hazard identifi cation, etc. The following ele-

ments of operational safety are recommended for inclusion

in every client’s IDC condenser safety plan/requirements:

Electric:

Confi gure all power switches and controls to pro-

vide an open, safe circuit before and during maintenance

procedures, until the unit is cleared by management for

normal on-line operations. For extended shutdowns it is

recommended that a qualifi ed technician remove fuses from

“fused-disconnect panels” or otherwise open the circuit in an

accepted, secure manner.

Fans

- All fan covers, guards, and shaft retainers (if any)

must be in place before applying power to an IDC condenser.

Always disengage and lock out power before allowing interior

inspections. To prevent foreign objects from being drawn

into rotating fan blades,

never

allow operation with hatch

off/open.

Enclosed space inspections

– Inspections of condenser

coil, drift eliminators, etc., requires machinery lockout and

the use of a “lookout buddy” at a minimum. Consult your

internal safety policy and OSHA requirements for additional

safety rules/procedures.

Vibration and noise

– Discontinue or stop machinery that

emits unusual vibration and noise. The source must be

investigated (and apparent discrepancies corrected) before

testing or placing the unit back in operation.

Wet Surface Precautions

– Poorly maintained/wetted

machinery requires care to avoid electrical shocks from in-

adequate/loose fi eld wiring/connections. All personnel must

lock out and tag machinery before working on the condenser.

Proper safety precautions such as the use of insulating

soles/gloves and a trained “lookout buddy” are indispensable.

Ice formation in cold weather can present fall/slip hazards.

Icing safety procedures should be mandatory when the daily

ambient temperature falls below 40°F (4.4°C).

Section 1.0 Pre-Installation

1.1 Preface

The evaporative-cooled, Induced Draft Condenser (IDC)

you have purchased utilizes the fi nest in engineered design,

materials, and corrosion protection to provide a rugged, long-

lasting unit. This manual provides the information needed for

safe installation, operation, and maintenance. Close attention

to the instructions and guidelines provided in this manual will

ensure a long satisfactory unit life and dependable operation

and performance.

Before rigging or beginning work on the unit, Imeco recom-

mends that experienced Refrigeration contractors, opera-

tors, and maintenance technicians be formally trained on

the IDC design and features - with this manual’s reading

as a

minimum

requirement. After installation, the unit (as

selected) must also be properly connected to appropriately

designed and installed refrigeration and water treatment

systems. The engineering plans, piping layouts, etc. for the

IDC and associated system components must be detailed in

accordance with local/governing codes and the best industry

standards and practices such as those outlined in up-to-date

industry literature.

Should you have any comments or questions regarding this

manual or the IDC unit, you are urged to call your local sales

representative.

1.2 Shipment

Inspection

Upon arrival of the IDC condenser at the job site, the unit

should not be signed for until it is inspected to ensure that all

required parts have been received and are free of shipping

damage. Unpack all items and check against shipping lists

- any items that appears to be missing should be noted on

the shipping papers and reported to an Imeco representative.

The following parts should be inspected:

•

Sheaves, belts, bearings/supports

•

Fan blades, shaft, and motor/hood

•

Coil/s and water distribution spray header, pump,

strainers, and fl oat assembly

•

Drift eliminators and inlet louvers

•

Parts shipped loose in pan section

Parts shipped loose include fan guard, inlet louvers, assorted

nuts, bolts, washers, and mastic strip (a fl exible joint seal

stored on a continuous paper-backed roll). Accessory items

will likely be shipped “loose” in a sealed box that is secured

in the pan section.

1.3 Transit Damage Claims

The IDC unit owner’s authorized agent who signs for the

shipment is responsible for making damage claims (per

ICC requirement). Request immediate inspection and form

execution by the agent of the carrier. Contact YORK Re-

frigeration Systems (815-288-3859) to report damage or

shortage claims.

1.4 Unit

Identifi cation

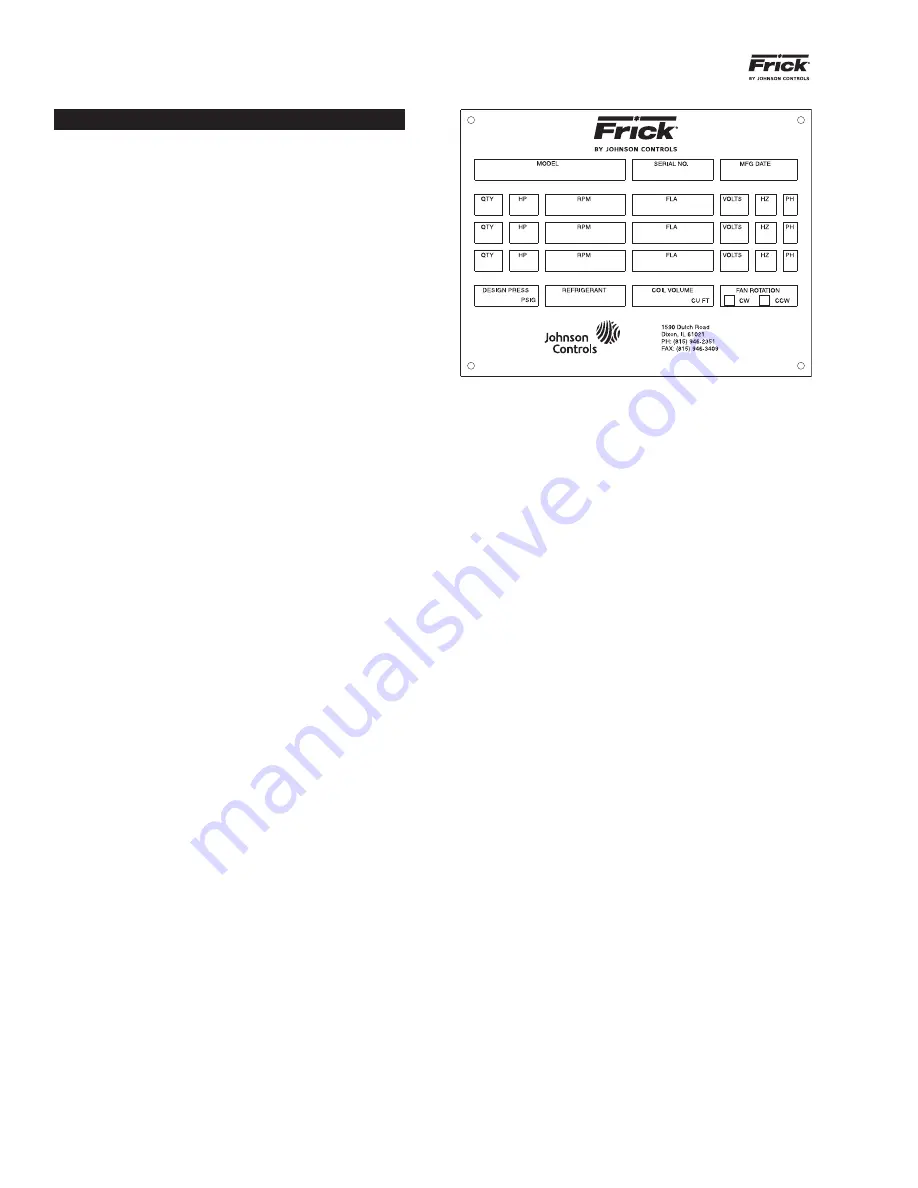

All IDC units are identifi ed by a nameplate permanently at-

tached to the pan section.

Figure 1-1. ID Plate Information

shows the information provided. Imeco recommends that

the name plate data be copied onto the graphic for ease of

reference ordering parts.

NOTE: When inquiring about the unit or ordering repair

parts, provide the MODEL and SERIAL NUMBERS from

the data plates.

Figure 1-1. ID Plate Information