ECH EVAPORATIVE CONDENSERS

MAINTENANCE

140.910-IOM (DEC 13)

Page 17

Adjustable Motor Base

Coat the motor base slides and adjusting screws (see Figure

10 in the Operation section) every 3 months using good quality

corrosion inhibiting grease such as one of those recommended

for lubricating the fan shaft bearings below.

WARNING

Check to ensure the controls for the fan motor are set to

allow a maximum of 6 on-off cycles per hour.

FAN SHAFT BEARINGS

Two pillow block ball bearings support the fan shaft. Each bearing

is equipped with a lubrication fitting and a slinger/locking collar

to keep out moisture.

Inspection and Maintenance

•

Lubricate the bearings with only a manual grease gun. Do

not use high-pressure grease guns since they may rupture

the bearing seals.

•

Lubricate the bearings with only one of the following

compatible water resistant greases* which are suitable

for ambient temperatures ranging from -65°F (-53.9°C) to

+250°F (121.1°C).

Amoco-Rycon Premium#3

MobilGrease

®

-AW2

Chevron-SRI

Shell-Alvania RL3™

Citgo-Polyurea MP2™

Shell-Alvania #3

Conoco-Polyurea 2™

Shell-Dolium “R”

Exxon-Polyrex

®

EM

SKF-LGHP2™

Exxon-Unirex N™

Unocal76-Unilife Grease™

*NOTE: List of brand names is for identification only and are

not exclusive recommendations.

•

Lubricate the bearings as follows:

1.

Initial Start-up:

Normally, no lubrication is required

since the bearings have been lubricated at the factory

prior to shipment. However, if the unit has been stored

at the job site for more than 1 year, both bearings

should be lubricated with new grease before initial

operation.

When lubricating, purge the old grease

from the bearing by gradually adding grease until

a bead of new grease appears at the seal on the

underside of the bearing.

2.

Seasonal Start-up:

Purge both bearings with new

grease prior to start-up.

3.

Operation:

Purge bearings every 2,000 hours of

operation or once every 3 months, whichever occurs

first.

4.

Extended Shutdown:

Purge bearings with new grease

prior to any prolonged storage or downtime.

HEAT TRANSFER SECTION

Fill and Drift Eliminator

The ECH has PVC fill with integral drift eliminators.

Inspection and Maintenance:

•

Inspect and clean the fill with the integral eliminators at

least quarterly.

•

The inspection procedure is as follows:

1. Shut off the fan and the spray pump.

2. Inspect the fill for obstructions, damage and fouling.

•

Remove any obstructions from the fill.

•

Remove any minor fouling chemically. Contact your local

water treatment consultant for advice.

•

Major fouling requires cleaning and flushing. Follow the

procedures listed in the SYSTEM CLEANING section at the

end of the MAINTENANCE section.

WATER DISTRIBUTION SYSTEM

The water is distributed through a corrosion resistant polyvinyl

chloride (PVC) system. The fill and drift eliminators are also

made of PVC, which requires no protection against rot, decay,

rust, or biological attack.

Inspect and clean the spray nozzles and heat transfer section

each month.

The inspection procedure is as follows:

•

Shut off the fan, but leave the spray pump running.

•

Check to see if the nozzles are producing the spray pattern

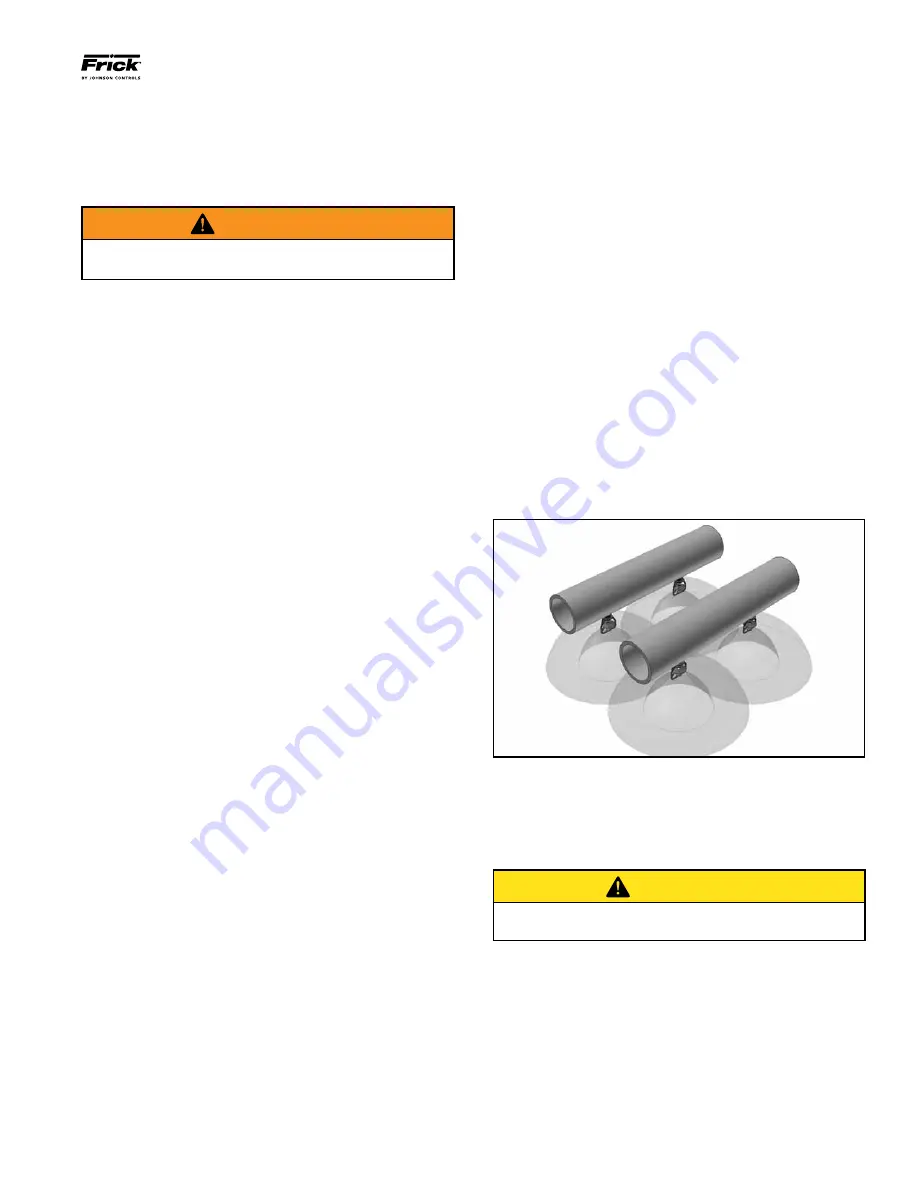

shown in Figure 15.

Figure 15 - Nozzle Spray Pattern

•

Clean any nozzles which are clogged. If necessary, the

nozzle and rubber grommet may be removed for cleaning.

•

Inspect the coil surface. Any corrosion, damage, or

obstructions must be corrected.

CAUTION

Don’t use steam or high pressure water to clean PVC

eliminators or materials other than steel.

WATER LEVEL CONTROL

There are two types of water level controls used on Frick units:

•

Mechanical makeup valve assembly

•

Optional electric water level control package

The ECH water makeup valve assembly is located on the air

inlet face.