129098-UIM-G-0411

Johnson Controls Unitary Products

9

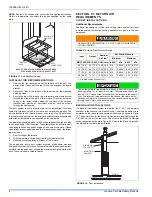

SECTION IV: FILTERS

FILTER INSTALLATION

All applications require the use of a filter. A standard air filter is located

in the return filter rack on the louvered door. The air filter(s) must be

replaced with air filter(s) that are the same size and same type.

Replacement filter size is shown in Table 3.

Downflow Filters:

There are two types of downflow filter racks.

1.

FURNACE FILTER RACK: A return filter rack with two standard

throwaway type filters are supplied on all models. The return filter

rack is located on the inside of the louvered door. This type of filter

rack is designed for two standard air filters only. Pleated Media or

Washable Filters cannot be used in this filter rack because they

cause too much pressure drop causing a reduction in airflow.

Refer to Figure 13.

2.

EXTERNAL RETURN FILTER GRILLE: The second type is an

external return air filter grille that

can only be used in applica-

tions where the furnace is installed in a closet

. This type of fil-

ter grille is typically installed in a closet door or wall with the filters

located within 12" (30.5 cm) of the return air opening of the fur-

nace. There must be a minimum clearance of 6" (15.2 cm)

between the front of the furnace and the closet door and/or the fur-

nace and the filter grille to prevent the return air flow from being

obstructed. Refer to Table 1 Unit Clearances to Combustibles.

NOTE:

Remove air filters inside louvered door when using an external

filter grille.

a.

If the standard throwaway filter are used the external filter

grille must have a minimum area of 540 in² (3483 cm²) which

would equal a 15" X 36" filter grille.

b.

If the Pleated Media or Washable Filters are used the exter-

nal filter grille must have a minimum area of 684 in² (4413

cm²) which would equal a 18" X 38" filter grille. The increased

area is to reduce the pressure drop across the air filter.

c.

Consideration should be given when locating the return filter

grille for maintenance.

d.

Any filter that has a large pressure drop should be checked to

be sure the pressure drop caused by the air filter will not pre-

vent the furnace from operating within the rise range, speci-

fied on the rating plate and in Table 7. If the furnace does not

operate within the specified rise range then a larger air filter

or an air filter that has a lower pressure drop must be

installed.

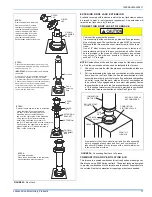

SECTION V: GAS LINE INSTALLATION

GAS SAFETY

.

GAS PIPING

Installation and Checking of Gas Line

Gas Supply piping must be sized in accordance with the recommenda-

tions contained in National Fuel Gas Code (ANSI-Z223.1, NFPA-54)

unless local codes or regulations state otherwise.

Materials used and pipe sizing for U.S. manufactured homes must com-

ply with requirements contained in Manufactured Homes A119.1, Rec-

reational Vehicles A119.2 and H.U.D. Title 24, Section 3280.705 and

any local or state codes.

NOTE:

The gas line inlet on the gas valve is 1/2-14 N.P.T. The gas line

may be installed through the furnace floor or furnace side to the gas

valve.

All installations must have a filter installed.

FIGURE 13:

Furnace Air Filters

Air Filters Can Be

Found On The Inside

Of This Panel

TABLE 3:

Filter Sizes - All Models

Input

Output

Air Flow

Cabinet Width

Door Filter

1

1. All Models shipped with disposable filters mounted inside upper furnace door.

2. Pleated filters have high pressure drop and require cleaning every 60 days.

3. Dirty filters can cause excess heating bills, lower air flow, and reduce heat exchanger life.

MBH

kW

MBH

kW

CFM

cmm

In

In

cm

56

16.4

44.8

13.1

1305

34.0

19 3/4

2 - 16 x 20 x 1

2 x 41 x 51

70

20.5

56

16.4

1305

34.0

19 3/4

2 - 16 x 20 x 1

2 x 41 x 51

77

22.5

62

18.1

1305

34.0

19 3/4

2 - 16 x 20 x 1

2 x 41 x 51

90

26.3

72

21.1

1305

34.0

19 3/4

2 - 16 x 20 x 1

2 x 41 x 51

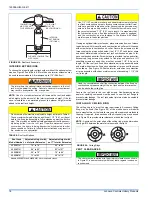

This furnace is designed to operate on NATURAL GAS or PRO-

PANE GAS ONLY. Do Not Burn any other Fuel in this furnace.

Burning any fuel except NATURAL GAS or PROPANE GAS can

cause premature heat exchanger burnout, high levels of carbon

monoxide, excessive sooting, a fire hazard, personal injury, prop-

erty damage and /or death.

An overpressure protection device, such as a pressure regulator,

must be installed in the gas piping system upstream of the furnace

and must act to limit the downstream pressure to the gas valve so it

does not exceed 0.5 PSI (14" w.c. (3.48 kPa). Pressures exceeding

0.5 PSI (14” w.c. (3.48 kPa) at the gas valve will cause damage to

the gas valve, resulting in a fire or explosion or cause damage to

the furnace or some of its components that will result in property

damage and loss of life.

If the gas input to the furnace is too great because of excessive gas

pressure, wrong size orifice, high altitude, etc., the burner flame will

be sooty and may produce carbon monoxide, which could result in

unsafe operation, explosion, and/or fire or asphyxiation.