129098-UIM-G-0411

18

Johnson Controls Unitary Products

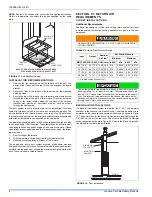

INTERIOR EXTENSIONS

To choose the proper length roof jack with or without the optional exten-

sion see Figure 25 and Table 8. More than one interior extension may

be used to accommodate A “dimensions up to 110” (284.5 cm).

NOTE:

Use of an interior extension will increase the roof jack adjust-

able heights by the amount of the interior extension height. If the fur-

nace is installed on an elevated plenum, the plenum height must be

added to the roof jack height.

Models 4000B8161 and 4000B8181 have removable crowns.

If using an optional interior extension, place extension down on furnace

top and mate with furnace flue and combustion air collar until it lines up

with screw holes in combustion air collar. Secure the extension to the

furnace using the pre-punched holes. Use 1/2” (1.27 cm) blunt or sharp

end sheet metal screws to fasten roof jack combustion air pipe to fur-

nace combustion air collar. Screw holes are provided in pipe and collar.

Excessively long screws may extend to flue pipe and puncture. it. If

substitute screws are used. they must not exceed 1 1/2” (3.8a cm) in

length. Pull the roof jack flue and combustion air pipe assembly down

and mate with extension flue and combustion air pipes until the screw

holes line up. See Figure 25. Fasten interior extension to combustion

air pipe assembly with sheet metal screws not exceeding 1 1/2” (3.8

cm) in length.

Secure the roof jack to the roof with screws. Non-hardening mastic

sealer or caulking compound must be used to seal the roof flange to

prevent water leakage. The roof jack swivel joint must also be sealed to

prevent water leakage.

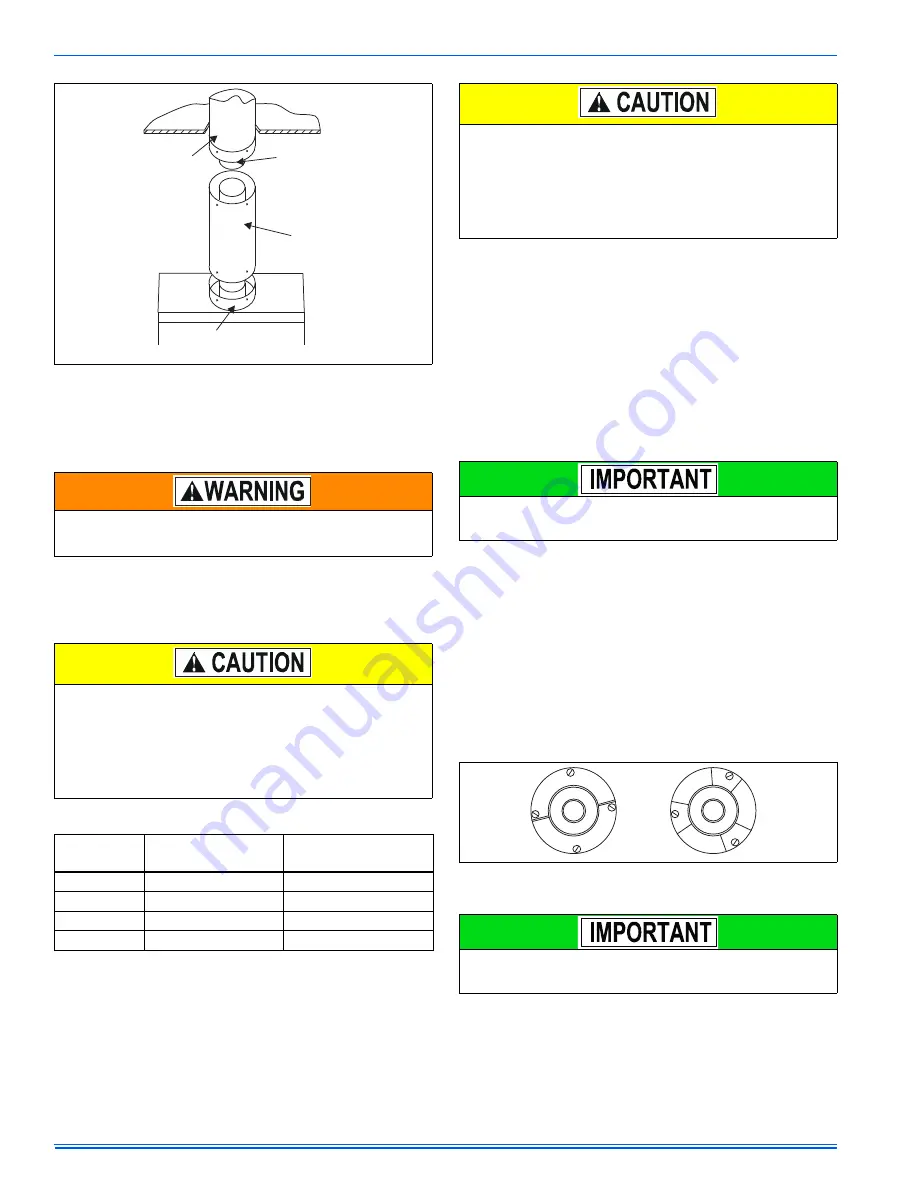

INSTALLING CEILING RING

The ceiling ring is to meet fire stop requirements. Accessory Ceiling

Ring may be used (See Figure 26) or the mobile home or modular

home manufacturer or the installer may use other approved methods to

fire stop. If required, three sections of the Accessory ring may be used

as in Figure 26 to provide closer clearance around the roof jack.

NOTE:

A portion of the outer edge of the ceiling ring may be trimmed so

the ring will fit between the warm air plenum and roof jack.

VENT CLEARANCES

FIGURE 25:

Roof Jack Assembly

The joint where the optional interior extension connects to the roof

jack must be below the ceiling. Failure to observe this requirement

may result in asphyxiation, fire, or explosion

Do not exceed the maximum adjustable height as listed in Table 6.

These maximum heights allow an additional 1 1/2” (3.81 cm) travel

before the flue pipe assembly is fully extended against the built-in

stop. This provides an additional safeguard against the flue assem-

bly being pulled from the roof jack if upward movement should

occur when the home is being transported or subjected to other

stress conditions. Failure to follow these instructions may result in

fire, explosion, or asphyxiation.

TABLE 6:

Roof Jack Options

Roof Jack

Model Number

Adjustable Height with

no Interior Extension

Adjustable Height with

on 17” Interior Extension

4000B7141

14” to 78”

64” to 95”

4000B7151

66” to 90”

83” to 107”

4000B8161

59” to 79”

76” to 96”

4000B8181

73” to 103”

90” to 110”

CEILING

COMBUSTION

AIR PIPE AND

FLUE ASSEMBLY

THIS JOINT

MUST BE

BELOW CEILING

INTERIOR

EXTENSION

(OPTIONAL)

FURNACE COMBUSTION

AIR COLLAR

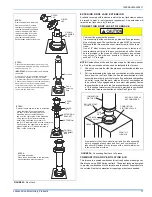

Use 1/2” (1.27 cm) blunt or sharp end sheet metal screws to fasten

roof jack combustion air pipe to furnace combustion air collar Screw

holes are provided in pipe and collar. Excessively long screws may

extend to flue pipe and puncture it. If substitute screws are used,

they must not exceed 1 1/2” (3.81 cm) in length. It is mandatory that

the combustion air and flue tube assembly be properly engaged,

and the combustion air pipe fastened to the furnace with sheet

metal screws in the holes provided.

Under no circumstances shall the connection between the flue and

combustion air pipe assembly of the roof jack and the interior exten-

sion be above the ceiling line.

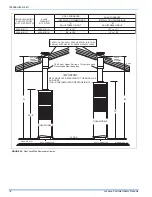

FIGURE 26:

Ceiling Rings

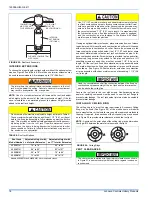

The vent must be installed with the minimum clearances as shown

in Figure 27, and must comply with local, state, regional codes and

requirements.

A

B