175619-XIM-C-0109

28

Johnson Controls Unitary Products

2.

Insert at least 203 mm (8") of 6.4 mm (1/4”) tubing

into each of these holes for sufficient penetration

into the air flow on both sides of the indoor coil.

NOTE:

The tubes must be inserted and held in a posi-

tion perpendicular to the air flow so that veloc-

ity pressure will not affect the static pressure

readings.

3.

Using an inclined manometer, determine the pres-

sure drop across a dry evaporator coil. Since the

moisture on an evaporator coil may vary greatly,

measuring the pressure drop across a wet coil

under field conditions would be inaccurate. To

assure a dry coil, the compressors should be deac-

tivated while the test is being run.

4.

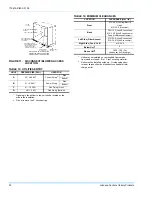

Knowing the pressure drop across a dry coil, the

actual air flow rate through the unit can be deter-

mined from the curve in Pressure Drop vs. Supply

Air Flow rate (Figure 13).

After readings have been obtained, remove the tubes

and reinstall the two 8 mm (5/16”) dot plugs that were

removed in Step 1.

NOTE:

De-energize the compressors before taking

any test measurements to assure a dry indoor

coil.

Failure to properly adjust the total system air

quantity can result in extensive blower dam-

age.

FIGURE 13 - PRESSURE DROP ACROSS COIL