18

Operating Instructions

•

Fillet weld joint:

Most fillet weld joints on metals of

moderate to heavy thickness will require multiple pass welds

to produce a strong joint. The sequence of lying multiple pass

beads into a T fillet joint and a lap fillet joint is shown below

(fig Z).

fig Z

1

1 2

3

2

3

Lap Joint Welded

In Three Passes

T Join in

Three Passes

JM-1998594-30

6.8 Spot welding

There are three methods of spot welding:

1.

Burn-through method:

In this method, two overlapped

metal pieces are welded together by burning through the

top piece and into the bottom piece. The wire suitable for

this method is a 0.035 inch self-shielding, flux-core wire.

Always select the high heat setting for this method and tune

in the wire speed prior to making a spot weld (fig a).

fig a

JM-1998594-31

Note:

Do not use a 0.030 inch self-shielding flux-core

wire when using this method unless the metal is very

thin, or excessive filler metal and minimal penetration are

acceptable.

2.

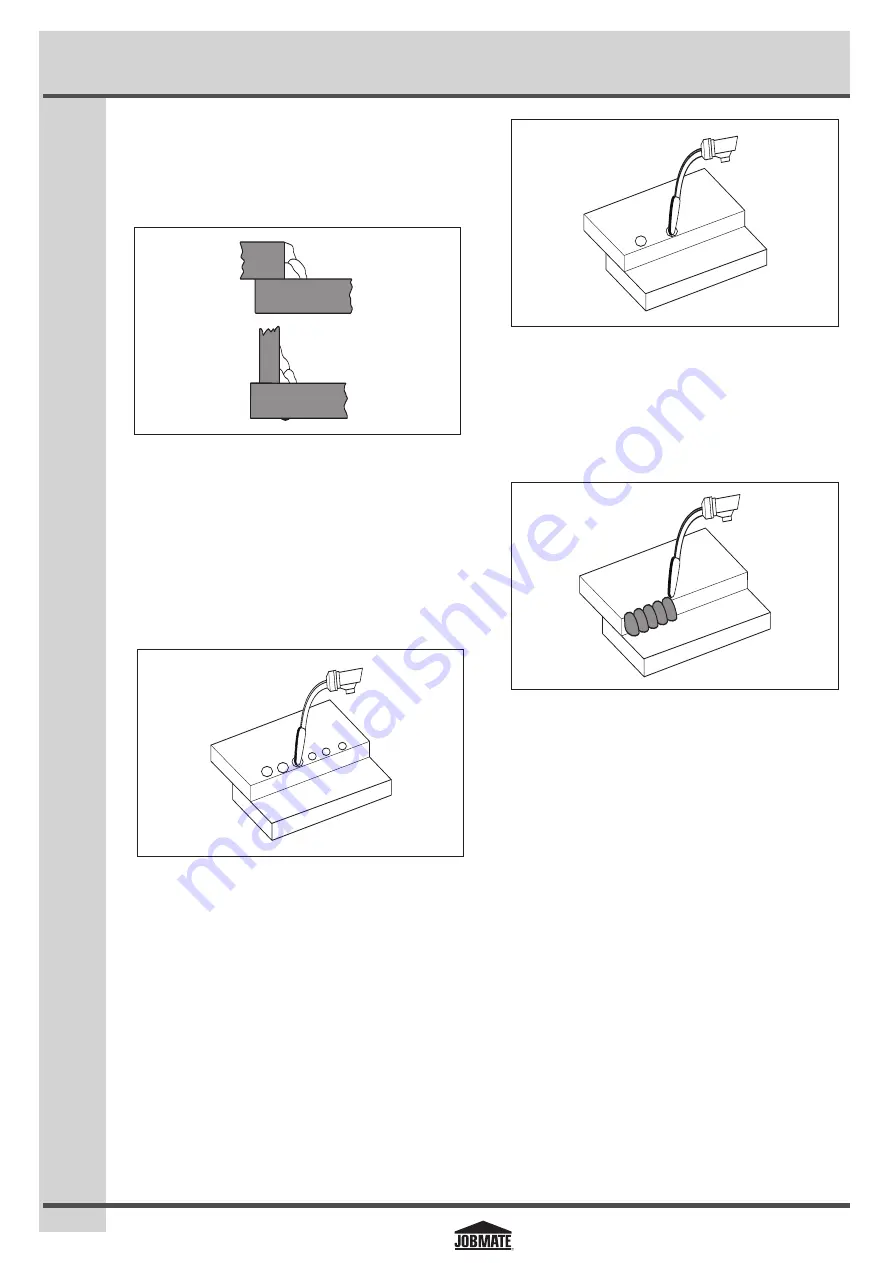

Punch and fill method:

This method produces a weld

with the most finished appearance. In this method, a hole

is punched or drilled into the top piece of metal and the arc

is directed through the hole to penetrate into the bottom

piece. The puddle is allowed to fill up the hole leaving a spot

weld that is smooth and flush with the surface of the top

piece (fig b).

fig b

JM-1998594-32

3.

Lap spot method:

The welding arc is directed to penetrate

the bottom and top pieces at the same time, and along each

side of the lap joint seam. Select the wire diameter, heat

setting, and tune in the wire speed so they are suitable for

welding the material with a continuous bead (fig c).

fig c

JM-1998594-33

Spot welding procedure

1. Select the wire diameter and heat setting recommended

above for the intended method of spot welding.

2. Tune in the wire speed as if a continuous weld is to be

performed.

3. Hold the nozzle piece completely perpendicular to and about

¼ inch off the workpiece.

4. Pull the trigger on the torch and release it when the desired

penetration is achieved.

5. Make practice spot welds on scrap metal and vary how long

the trigger is held until a desired spot weld is made.

6. Make spot welds on the actual workpiece at desired locations.