13

Assembly Instructions

5. Setting the wire spool tension:

a. Turn the wire spool (1) with one hand (fig I).

b. Increase the spool tension by tightening the wing nut (2)

while turning the spool. Turn the spool until it slows down

(fig I).

JM-1998594-13

fig I

NORMAL

NORMAL OVER CURRENT

SURINTENSITEE

ATTENTION: LE

CA

DE SOUDAGE

NO

GAS

GAS

1

2

3

4

6

5

1

2

c. Stop tightening the wing nut.

d. Repeat the above steps until proper spool tension is

achieved.

Note:

If high tension is applied to the wire spool, the wire slips

away from the drive roller groove. If less tension is applied, the

wire spool unspools itself when the trigger is released. Use the

wing nut to adjust the spool tension high or low.

6. Disconnect the welder from the power source, and remove

the leading end of the wire from the spool.

7. Cut off any bent portion of the wire using a wire cutter.

8. Loosen the tension adjusting knob holding the drive

tension arm in place and lift the tension arm up off the

drive roller.

9. Insert the wire into the inlet guide tube, and feed about

six inches of it across the drive roller and into the torch

assembly.

10. Line up the wire with the correct groove in the drive roller.

11. Place the drive tension arm above the drive roller.

12. Tighten the drive tension adjusting knob until the tension

roller is applying enough force on the wire to prevent it

from slipping in the drive roller.

13. Plug in and turn the welder ON. Set the voltage switch to

the voltage setting recommended for the gauge of metal

that is to be welded. Refer to page 11 for set up chart on

the back side of the wire drive compartment.

14. Set the wire speed control. Straighten the MIG gun cable

and pull the trigger in the gun handle to feed the wire

through the torch assembly.

15. Turn the power switch to the OFF position. Select a contact

tip that has the same diameter as the wire being used.

Note:

Due to inherent variances in flux-core welding wire, it is

necessary to use a larger-sized contact tip than the wire.

16. Slide the contact tip over the wire, thread the contact tip

into the end of the gun and tighten securely.

17. Install the nozzle onto the gun assembly, and cut off excess

wire that extends past the end of the nozzle.

WARNING

ENSURE THAT WIRE PASSING OUT OF THE END OF THE TORCH

DOES NOT CONTACT THE WORKPIECE, GROUND CLAMP OR ANY

GROUNDED MATERIAL DURING THE DRIVE TENSION SETTING

PROCESS, AS DOING SO MAY REDUCE THE RISK OF ARC FLASH.

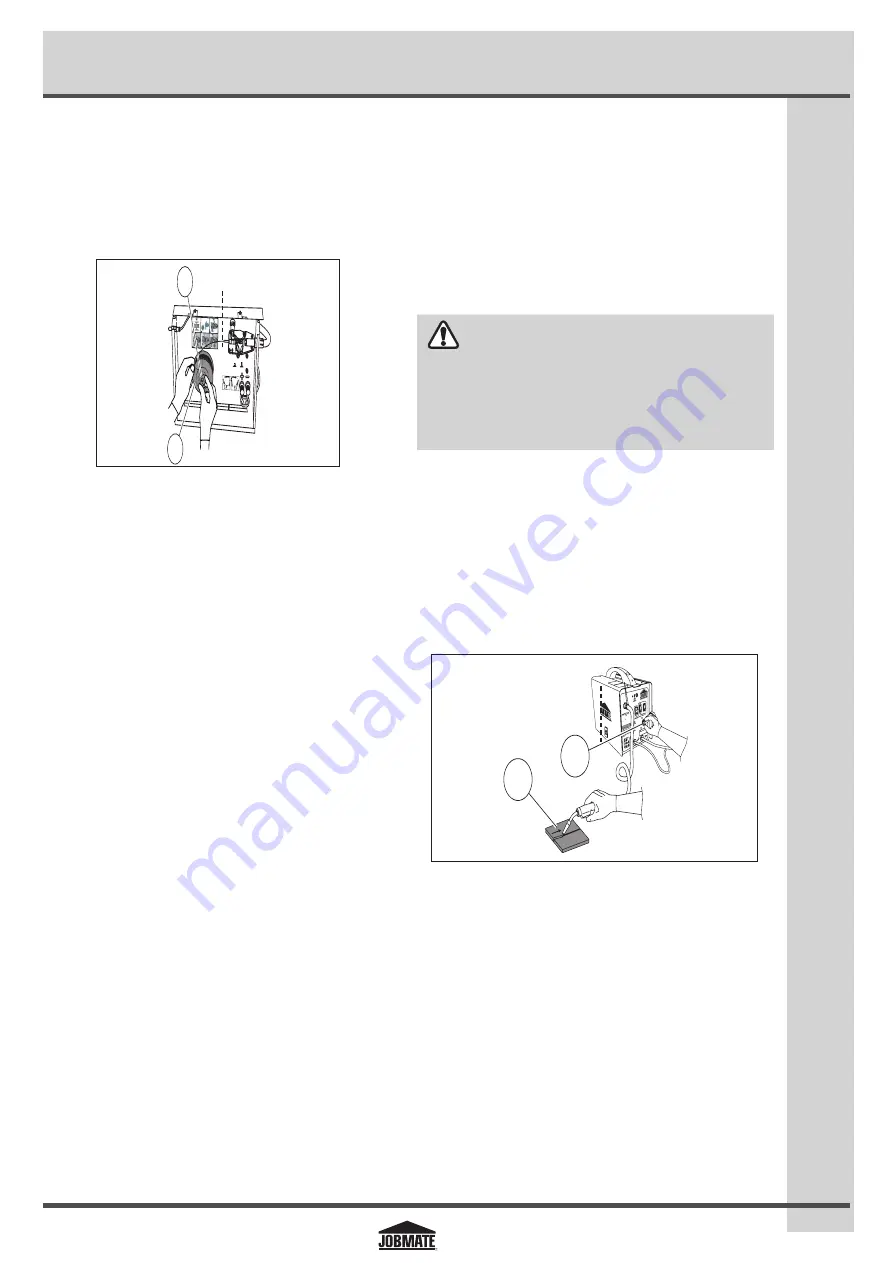

5.4 Setting the wire feed speed

1. To set the wire feed speed, initiate the welding operation

using the scrap workpiece (1).

2. While welding the scrap workpiece, turn the wire speed

adjustment knob (2) clockwise, and increase the wire

speed until the wire seems to feed smoothly without

slipping (fig J).

JM-1998594-14

1

2

WIRE FEE

D

ENTRAI

NEMEN

T

199-859 6

SOUDEUSE A D V

IDAGE

DE FIL- LECTRO

DE SOUS

GAZ

MIG/FLUX

-CORE WI

RE FEED WELDER

INERTE OU A AM

E EN FLU

X

1

2

3

4

5

6 7

8

WARN

ING/A

VERT

ISSE

MEN

T

. This

weld

er is

for u

se on

a 20

A br

anch

circu

it.

DO N

OT REM

OVE

THIS

LAB

EL /

N’EN

LEVE

Z PAS

CET

TE ÉT

IQUE

TTE.

. If co

nnec

ted t

o a c

ircuit

prot

ected

by fu

ses,

use a

time

-dela

yed f

use m

arked

“D”.

. Cet

te so

udeu

se re

quier

t un c

ircuit

de 2

0 A.

. Se l

a sou

deus

e est

bran

chée

á un

circu

it pro

tégé

par f

usibl

es, u

tilise

z un

fusib

le

tem

poris

é ma

rqué

<< D

>>.

1

fig J

2