SECTION 2 - GENERAL

3121290

– JLG Lift –

2-1

SECTION 2. GENERAL

2.1

MACHINE PREPARATION, INSPECTION, AND

MAINTENANCE

General

This section provides information needed by personnel

responsible to place machine in operation readiness and

maintain its safe operating condition. For maximum service

life and safe operation, ensure all necessary inspections and

maintenance have been completed before placing machine

into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive

inspection and preventive maintenance program. The follow-

ing table outlines periodic machine inspections and mainte-

nance recommended by JLG Industries, Inc. Consult your

national, regional, or local regulations for further requirements

for aerial work platforms. Frequency of inspections and main-

tenance must be increased as environment, severity and fre-

quency of usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a

machine Pre-Start Inspection before use daily or at each

change of operator. Reference the Operator’s and Safety Man-

ual for completion procedures for Pre-Start Inspection. Opera-

tor and Safety Manual must be read in its entirety and

understood before Pre-Start Inspection.

Pre-Delivery Inspection and Frequent Inspection

Pre-Delivery Inspection and Frequent Inspection shall be per-

formed by a qualified JLG equipment mechanic. JLG Indus-

tries, Inc. recognizes a qualified JLG equipment mechanic as a

person who, by possession of a recognized degree, certificate,

extensive knowledge, training, or experience, has successfully

demonstrated the ability and proficiency to service, repair, and

maintain the subject JLG product model.

Pre-Delivery Inspection and Frequent Inspection procedures

are performed in the same manner, but at different times. Pre-

Delivery Inspection shall be performed before each sale, lease,

or rental delivery. Frequent Inspection shall be accomplished

for each machine in service for 3 months or 150 hours (which-

ever comes first); out of service for a period of more than 3

months; or when purchased used. Frequency of this inspec-

tion must be increased as environment, severity and fre-

quency of usage requires.

Reference JLG Pre-Delivery and Frequent Inspection Form and

Inspection and Preventative Maintenance Schedule for items

requiring inspection during these inspections. Reference

appropriate areas of this manual for service and maintenance

procedures.

Annual Machine Inspection

Annual Machine Inspection must be performed on an annual

basis, no later than thirteen (13) months from date of prior

Annual Machine Inspection. JLG Industries recommends this

task be performed by a Factory-Trained Service Technician. JLG

Industries, Inc. recognizes a Factory-Trained Service Technician

as a person who has successfully completed the JLG Service

Training School for the subject JLG product model. Reference

machine Service and Maintenance Manual and appropriate

JLG inspection form for this inspection.

Reference JLG Annual Machine Inspection Form and Inspec-

tion and Preventative Maintenance Schedule for items requir-

ing inspection during per formance of this inspection.

Reference appropriate areas of this manual for service and

maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each Annual

Machine Inspection, notify JLG Industries, Inc. of current

machine ownership.

Preventative Maintenance

With specified inspections, maintenance shall be performed

by a qualified JLG equipment mechanic. JLG Industries, Inc.

recognizes a qualified JLG equipment mechanic as a person

who, by possession of a recognized degree, certificate, exten-

sive knowledge, training, or experience, has successfully dem-

onstrated the ability and proficiency to service, repair, and

maintain the subject JLG product model.

Reference Preventative Maintenance Schedule and appropri-

ate areas of this manual for service and maintenance proce-

dures. Frequency of service and maintenance must be

increased as environment, severity and frequency of usage

requires.

Содержание 450A II Series

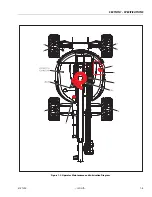

Страница 21: ...SECTION 1 SPECIFICATIONS 3121290 JLG Lift 1 5 Figure 1 2 Operator Maintenance and Lubrication Diagram ...

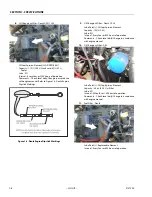

Страница 44: ...SECTION 3 CHASSIS TURNTABLE 3 4 JLG Lift 3121290 Figure 3 3 Drive Hub and Brake Assembly 2WD and 4WD ...

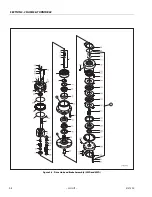

Страница 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Страница 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

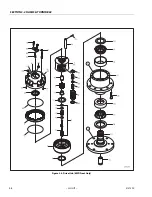

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Страница 107: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 67 Figure 3 47 Deutz EMR 2 Troubleshooting Flow Chart ...

Страница 108: ...SECTION 3 CHASSIS TURNTABLE 3 68 JLG Lift 3121290 Figure 3 48 Deutz EMR 2 Vehicle Side Connection Diagram ...

Страница 109: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 69 Figure 3 49 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2 ...

Страница 110: ...SECTION 3 CHASSIS TURNTABLE 3 70 JLG Lift 3121290 Figure 3 50 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2 ...

Страница 111: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 71 Figure 3 51 EMR 2 Engine Plug Pin Identification ...

Страница 112: ...SECTION 3 CHASSIS TURNTABLE 3 72 JLG Lift 3121290 Figure 3 52 EMR 2 Vehicle Plug Pin Identification ...

Страница 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Страница 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Страница 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Страница 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Страница 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Страница 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Страница 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Страница 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Страница 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Страница 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Страница 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Страница 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Страница 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Страница 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Страница 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Страница 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Страница 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Страница 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Страница 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Страница 337: ...SECTION 6 JLG CONTROL SYSTEM 3121290 JLG Lift 6 27 Figure 6 11 System Test Flow Chart Platform Tests ...

Страница 339: ...SECTION 6 JLG CONTROL SYSTEM 3121290 JLG Lift 6 29 Figure 6 12 System Test Flow Chart Ground Station Tests ...

Страница 350: ...SECTION 6 JLG CONTROL SYSTEM 6 40 JLG Lift 3121290 Figure 6 13 Control Module And Fault Code Light Locations ...

Страница 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Страница 380: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 10 JLG Lift 3121290 Figure 7 26 Electrical Components 1 of 2 ...

Страница 381: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121290 JLG Lift 7 11 Figure 7 27 Electrical Components 2 of 2 ...

Страница 388: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 18 JLG Lift 3121290 Figure 7 34 Main Hydraulic Schematic 1 of 2 ...

Страница 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Страница 395: ......