9629 Microprocessor Controller

- 15 -

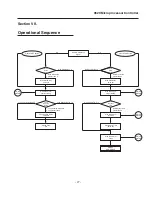

Section VI.

Modes of Operation

A. Operator Mode

This is the mode which is used by the operator to

run the wire feeder. The system is automatically

set to this mode when the control is switched

on.

To set the conditions for operation, the operator

can scroll through the various screens and make

the appropriate changes. These changes will be

displayed on the top line of the display.

As the system is operating, various informa-

tion messages appear on the lower line of the

display.

Display Screens - Upper Line

Screen 1 WELCOME SCREEN

This screen appears automatically when the unit

is switched on and remains on the screen for ap-

proximately 3 seconds. It identifies the model

of the control.

The next screen will appear automatically.

Screen 2 WIRE SPEED

When the second screen appears, it displays the

current level of wire feed speed. If this speed

is correct, the start button can be pressed to im-

mediately initiate wire feed. If the 9629 is part

of a system, a remote signal can initiate the start

delay prior to the wire feeding.

Jetline Engineering

Model 9629

WIRE SPEED

40.0ipm

Speed will be displayed in IPM (inches per min-

ute) or CPM (centimeters per minute). Selection

of IPM or CPM is made in the calibration mode

(see Screen 30)

.

If it is desired to change the speed, this is done

by turning the adjust knob to increase or de-

crease the speed as necessary. As the change

is made, the number on the display changes

accordingly.

The wire feed speed can be adjusted from the

minimum to maximum value which has been

set in the calibration mode (see Screens 21 and

24).

Press the touch pad with the down arrow to

proceed to the next screen.

Screen 3 START DELAY

This screen allows a start delay to be set by

turning the adjust knob to increase or decrease

its value. As the change is made, the number on

the display changes accordingly. (This feature is

active only if remote start is used).

When the remote start signal is received, wire

feed will be inhibited until the start delay has

timed out. After the start delay has elapsed,

wire feed will commence at the speed which

has been preset.

The start delay is used to start wire feeding at the

correct time in the weld start up sequence. If the

9629 controlled wire feeder is part of a system

and a power supply with current upslope is be-

ing used, it is recommended to initiate wire feed

when the current has sloped up to about 75% of

its weld value. This will ensure that the weld

pool is correctly established before wire starts to

feed. If, for example, the total time for initial

current and upslope is set to two seconds on the

welding power supply, a wire start delay of ap-

proximately 1.5 seconds would be appropriate.

START DELAY

2.8sec

Содержание 9600 Series

Страница 2: ...9629 Microprocessor Controller 2...

Страница 6: ...9629 Microprocessor Controller 6...

Страница 41: ...9629 Microprocessor Controller 41 Figure 1 Enclosure SUB PANEL GROUND MAIN GROUND...

Страница 43: ...9629 Microprocessor Controller 43 Figure 2 Enclosure Door...

Страница 49: ...9629 Microprocessor Controller 49 S1 CONNECTOR...

Страница 50: ...9629 Microprocessor Controller 50 S2 CONNECTOR...

Страница 51: ...9629 Microprocessor Controller 51 S3 CONNECTOR...

Страница 52: ...9629 Microprocessor Controller 52...

Страница 53: ...9629 Microprocessor Controller 53 Interconnection Diagram...