9

The planer should be operated in a well-lit area with

good ventilation.

Exposed metal surfaces, such as tables, rollers,

cutterhead, etc., may have been given a protective

coating at the factory. This can be removed with a

soft cloth moistened with a good commercial

solvent. Do not use acetone, gasoline, lacquer

thinner, or other solvents with a low flash point. Do

not use an abrasive pad because it may scratch

metal surfaces.

Use care when cleaning around

cutterhead area; knives are extremely sharp.

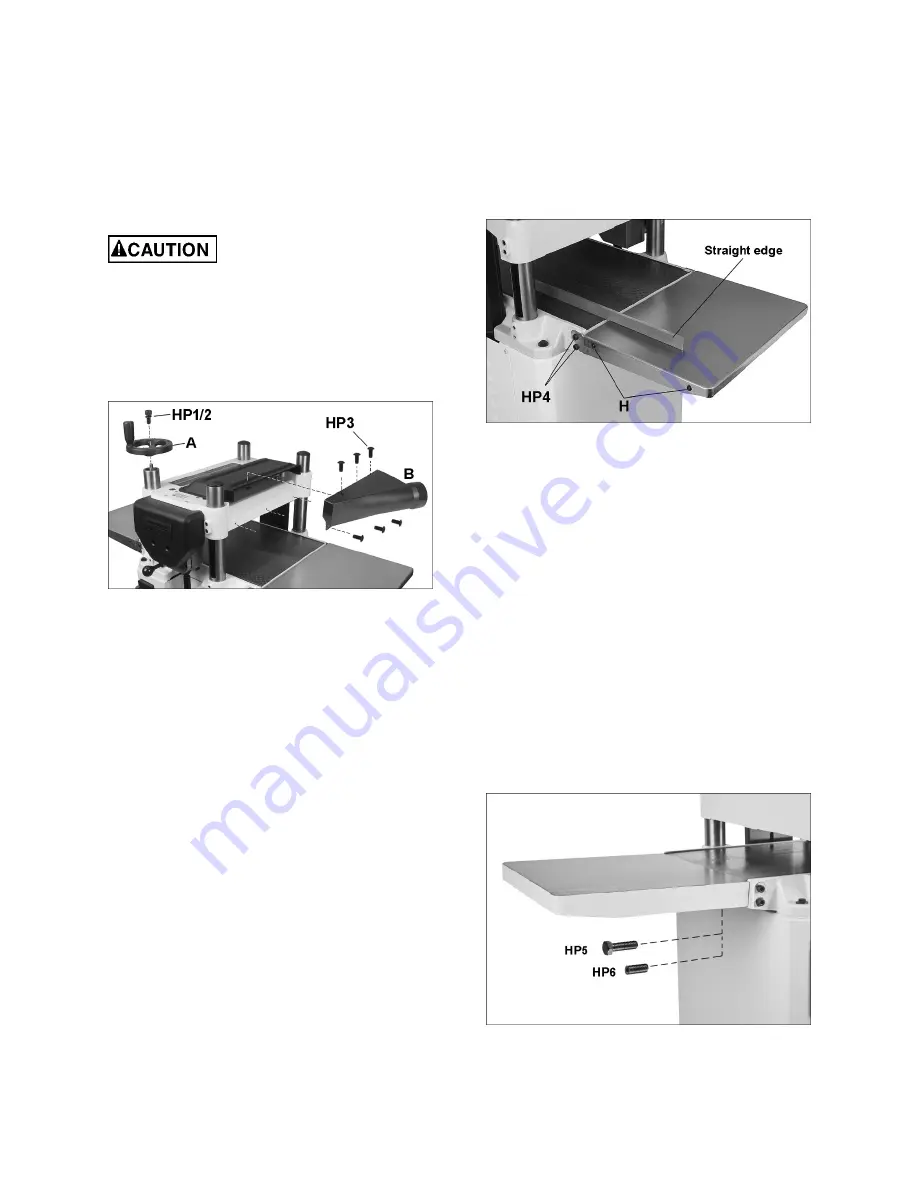

5.4

Handwheel

Install handwheel (A) onto shaft, making sure to

orient it with the flat on the shaft. Insert socket hd

cap screw with lock washer (HP1,HP2) and tighten.

See Figure 5-3.

Figure 5-3: handwheel and dust port

5.5

Dust Port

Mount dust port (B) to rear of head casting with six

button head screws (HP3). See Figure 5-3.

It is strongly recommended that you use a dust

collection system (not provided) with this planer.

Connect a 4-inch dust hose to the port and secure

with a hose clamp. Visit JET’s website or contact

your dealer for a complete line of dust collectors.

IMPORTANT:

If you are not using a dust collection

system, do not attach the dust port to the planer, as

the accumulation of dust inside the port may create

a safety hazard, or eventually cause jamming of the

rollers.

5.6

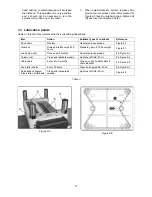

Extension tables

The JWP-15B is shipped with steel tables. The

JWP-15BHH is shipped with cast iron tables.

JWP-15B only:

1. Mount the steel extensions to the main table

using the screws provided (HP4, Figure 8-9).

The bottom screw is used as a stop. The

extension table pivots on the top screw.

2. The extension tables must be leveled with the

main table. A straight steel bar is ideal for this,

but a carefully jointed board may also be used.

Place the straight edge across extension table

and main table, as shown in Figure 5-4. Move

the straight edge to different places along the

table width during the alignment process.

3. Loosen screws (H) with provided Torx point

screwdriver and adjust table up or down at each

of the four corners as needed until straight edge

sits flush across both tables at all points.

Tighten screws (H).

Figure 5-4: extension tables (JWP-15B only)

JWP-15BHH only:

1. Insert 3 set screws (HP6, Figure 5-5) into the

lower holes of a cast iron extension table.

2. Mount the extension table with three hex cap

screws (HP5) using a 13mm wrench. Do not

fully tighten yet.

3. Place a straight edge (straight steel bar or

carefully jointed board) across extension table

and main table, as shown in Figure 5-4.

4. Adjust extension table until it is even with main

table, and snug the screws (HP5) a little more.

Then turn any of the 3 set screws in or out as

needed until straight edge sits flush with

extension table and main table at various points

along their width.

5. Tighten hex cap screws (HP5).

6. Repeat for opposite extension table.

Figure 5-5: extension tables (JWP-15BHH only)

Содержание JWP-15B

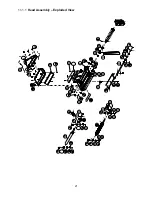

Страница 21: ...21 11 1 1 Head Assembly Exploded View ...

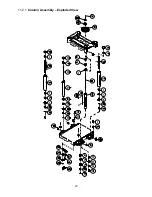

Страница 23: ...23 11 2 1 Column Assembly Exploded View ...

Страница 26: ...26 11 4 1 Gear Box Assembly Exploded View ...

Страница 28: ...28 11 5 1 Cabinet Assembly Exploded View ...

Страница 32: ...32 12 0 Electrical Connections for JWP 15B 15BHH ...

Страница 34: ...34 This page intentionally left blank ...

Страница 35: ...35 This page intentionally left blank ...

Страница 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...