12

11. Tighten all gib screws on the other two knives

in the same fashion, until all gib screws on the

cutterhead are firmly tightened.

(NOTE: The purpose of this incremental

tightening process is to prevent any slight

deflection or warpage of the cutterhead, and to

ensure that each knife is completely seated into

the slot.)

After installing knives,

check again carefully. Make certain all gib

screws are tightened securely. Loose knives

can be propelled at high speed from a

rotating cutterhead, causing injury.

12. Re-install top cover and dust hood.

7.3

Replacing/rotating knife inserts

(JWP-15BHH only)

The knife inserts on the JWP-15BHH are four-sided.

When dull, simply remove each insert, rotate it 90°

for a fresh edge, and re-install it.

Use a provided star-point driver (F, Figure 5-1) to

remove the knife insert screw.

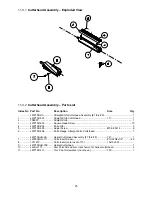

Figure 7-4

It is advisable to rotate all inserts at the same time

to maintain consistent cutting. However, if one or

more knife inserts develops a nick, rotate only those

inserts that are affected.

Each knife insert has an etched reference mark so

you can keep track of the rotations.

IMPORTANT:

When removing or rotating inserts,

clean saw dust from the screw, the insert, and the

cutterhead platform. Dust accumulation between

these elements can prevent the insert from seating

properly, and may affect the quality of the cut.

To install new knife inserts:

1. Disconnect machine from power source.

2. Remove dust hood and top cover.

3. Insert provided Torx driver into hole through belt

guard (see B, Figure 7-2). Use this to rotate the

cutterhead during the procedure.

CAUTION:

Always remove hex wrench

before starting planer.

4. Before installing each screw, lightly coat the

screw threads with machine oil and wipe off any

excess.

5. Position knife insert and move it back and forth

to verify there are no burrs or dirt.

6. Hold insert away from the back of the seat (pull

slightly toward yourself if facing the cutting

edge) and allow the screw to pull insert into

position. Note: A slight offset between screw

hole and hole in knife insert is normal. Do not

position insert directly over screw hole, as it

could ride up on the back of the seat and

potentially cause cracking of the tip.

7. Securely tighten each knife insert screw before

operating the planer.

IMPORTANT:

Maximum torque for tightening the

screws is 45 to 55 inch pounds (3.75 to 4.6 foot

pounds).

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propelled at high speed from a rotating

cutterhead, causing injury.

8.0

Operation

8.1

Start switch

See Figure 8-1.

Press green switch to start planer. Press red switch

to stop.

To prevent unauthorized or accidental starting of the

planer, remove safety key from switch and store in

a safe place. Key must be reinserted to start planer.

Figure 8-1

The planer is equipped with overload protection. If

an excess of current is detected, the machine will

shut off to prevent damage to motor. If this occurs,

wait a few minutes for the machine to cool down,

then press the reset button behind the stop paddle.

Содержание JWP-15B

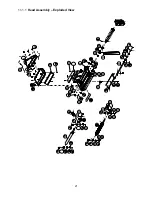

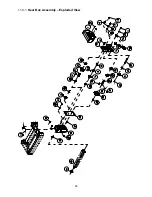

Страница 21: ...21 11 1 1 Head Assembly Exploded View ...

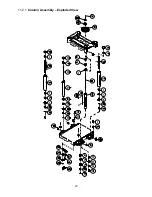

Страница 23: ...23 11 2 1 Column Assembly Exploded View ...

Страница 26: ...26 11 4 1 Gear Box Assembly Exploded View ...

Страница 28: ...28 11 5 1 Cabinet Assembly Exploded View ...

Страница 32: ...32 12 0 Electrical Connections for JWP 15B 15BHH ...

Страница 34: ...34 This page intentionally left blank ...

Страница 35: ...35 This page intentionally left blank ...

Страница 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...