17

Important

•

After servicing, complete the relevant Service

Interval Record section of the Benchmark

Checklist located on pages 20 and 21 of this

document.

•

Servicing should only be carried out by competent

persons in the installation and maintenance of

unvented water heating systems.

•

Any spare parts used MUST be authorised parts.

•

Disconnect the electrical supply before removing

any electrical equipment covers.

•

NEVER bypass any thermal controls or operate

system without the necessary safety valves.

•

Water contained in the cylinder may be very hot,

especially following a thermal control failure.

Caution must be taken when drawing water from

the unit.

Spare Parts

A full range of spare parts are available for the

cylinder range (Table 05, page 18). Refer to the

technical data label on the unit to identify the model

installed and ensure the correct part is ordered. You

will need to quote the serial number, which is printed

on the data label.

Fault Finding

The fault finding chart (Table 04, below) will enable

operational faults to be identified and their possible

causes rectified. Any work carried out on the

unvented water heater and its associated controls

MUST be carried out by a competent installer for

unvented water heating systems. In case of doubt

contact

service support (see contact details on back

page).

Warning

DO NOT TAMPER WITH ANY OF THE SAFETY

VALVES OR CONTROLS SUPPLIED WITH THE

CYLINDER AS THIS WILL INVALIDATE ANY

GUARANTEE.

Fault Finding & Servicing

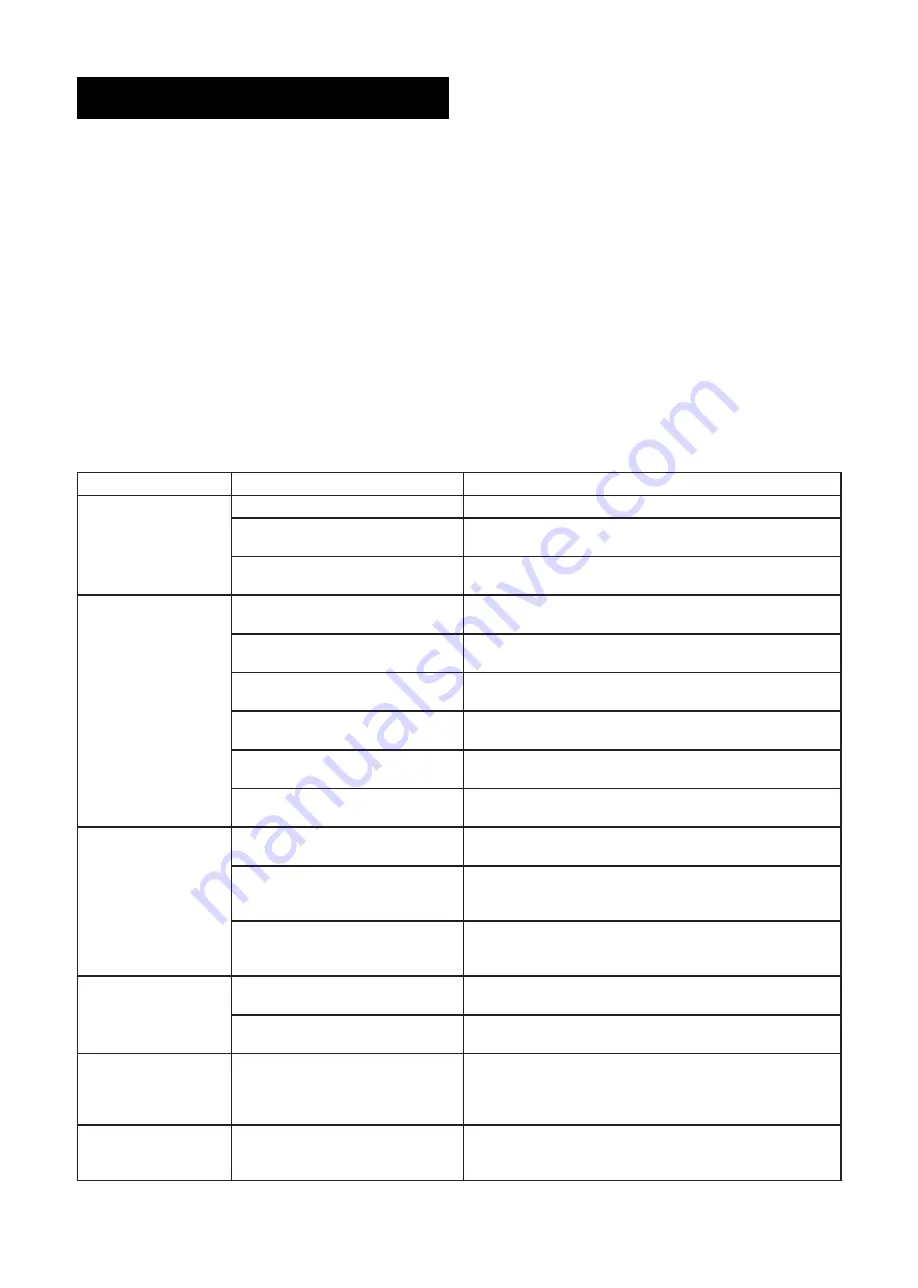

Fault

Possible cause

Remedy

No hot water

1. Mains water supply off.

1. Check and open stop cock.

2. Strainer blocked.

2. Turn off water supply. Remove strainer and clean (

see page 31).

3. Cold water combination valve

incorrectly fitted.

3. Check and refit as required.

Water from hot taps

is cold

1. Back up immersion heater not

switched on.

1. Check and switch on.

2. Back up immersion heater

thermal cut-out has tripped.

2. Check. Reset by pushing button (Figure 10, page 14).

3. Indirect programmer set to

central heating only.

3. Check. Set domestic to a hot water programme.

4. Indirect boiler not working.

4. Check boiler operation. If fault is suspected consult

boiler manufacturers instructions.

5. Indirect thermal cut-out has

tripped.

5. Check. Reset by pushing button. Check operation of

indirect thermostat (Figure 10, page 14).

6. Indirect motorised valve not

connected correctly.

6. Check wiring and/or plumbing connections to

motorised valve (see Figures 8 & 9, page 13).

Water discharges

from expansion relief

valve

1. Intermittently. Air volume in the

cylinder has reduced

1. See page 16 for details on how to test and recharge.

2. Continually. 3 bar pressure

reducing valve is not working

correctly.

2. Check pressure from 3 bar pressure reducing

valve. If greater than 3 bar replace pressure reducing

cartridge.

3. Continually. Expansion valve

seat damaged.

3. Remove expansion relief cartridge from 8 bar

pressure relief valve and check seating, if necessary fit

new cartridge.

Water discharges

from the T&P valve

intermittently

1. Air volume in the cylinder has

reduced

1. See page 16 for details on how to test and recharge.

2. 8 bar expansion relief valve

faulty.

2. Check valve and replace if necessary

Water discharges

from the T&P valve

continually

1. Thermal control failure. Note

water will be very hot.

1. Switch off power supply to immersion heater(s) and

shut down the boiler. DO NOT turn off the water supply.

When discharge stops check all thermal controls,

replace if faulty.

Milky water

1 Oxygenated water.

1. Water from a pressurised system releases oxygen

bubbles when flowing. The milkiness will disappear

after a short while.

Table 04: Fault Finding Chart

Содержание 120i

Страница 22: ...22 Notes...

Страница 23: ...23 Notes...