5

Knives and counter – knife

Observe to re – thighten screws by using the safety discs. The machine is equipped

with a simply exchangeable and reversable counter – knife in tapered execution. It

has two sharp edges. Used cutting edges may be re – welded by electrodes of 250 –

300 kg consistency and re – grinded for usable sharp edges. (Hardness approx. 60

HRC). Avoid from dirt when re – mounting the counter – knife, clean the surfaces

from dirt and chips.

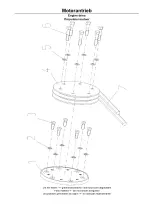

Power requirements

Depending from material to be chopped at minimum 9 HP (6,6 KW)

Chipping lenth

Only hydraulic valve = approx. 20mm

Hydraulic capacity regulator = 5 up to 20mm (larger pieces on request).

Attention:

Use only spare parts origine JENSEN. No warranty in case of using other

products. In case of spare part order always mention the number of this machine.

Technical Specifications for woodchippers

Maximum wood diameter: (depending on wood and engine)

A141 = 24cm

A231 = 22cm

A328 = 16cm

A325 = 16cm

A425 = 15cm

A521 = 12cm

A518 = 10 cm

A528 = 15cm

On heavy feed please watch the rpm of the chipper – disk!

In case the rpm drops you should diengage the hydraulic feed rollers and do not

engage again before the machine is back to the full rpm.

Necessary power:

with 2 knife and mixed bushwork you need about 6.6 KW.

The power you really need depends on the sorting and the kind of the wood, the

speed of feed and the number of knifes in your machine.

Chipping – length:

Using hydraulic feed rollers you can adjust the length between 0

and 5cm with the regulator (special order).

Caution!

Knife – screws and all screw on the transportation – axle should be

controlled regularly and tightened following the table:

Forces for bolts and nuts class 8.8:

Size

Nm

kpm

M20

410

41

M16

210

21

M12

86

8,6

M10

49

4.9

M8

25

2,5

M6

10

1

¾“

340

34