7

BURNING WOOD

by brushing and scraping off the accumulated smut through the cleansing and filling hatches.

•

Pull the firing throat out of the boiler furnace

•

Open the air dampers of the holes.

and remove ash that has remained from

previous burning. After removing ash, push the

firing throat back up to the rear wall of the

furnace.

•

Put kindling wood onto the rear bar (< 200 mm

long and < 20 mm in diameter) and insert

kindling paper or bark between billets.

•

Light the fire. Keep the filling hole slightly

If the boiler has not been used for a long while,

open and the maintenance hole air damper

use a small amount of wood to ensure that water

closed when kindling the fire.

that has soaked into the ceramic bars does not

•

Wait for about 15 minutes until there is a bed

of live coals on the grate bar.

•

Put billets bark up onto the grate bar equally

and tightly so that the billets touch the rear wall

of the furnace.

•

Then put a new charge of billets onto remaining

coals.

•

When coals burn down, close the air dampers in

order to avoid heat losses from the flue duct.

One charge of wood produces approx. 50 kWh of

heat i.e. 1000 l of water is heated approx. at

40°

С

.

Cleaning

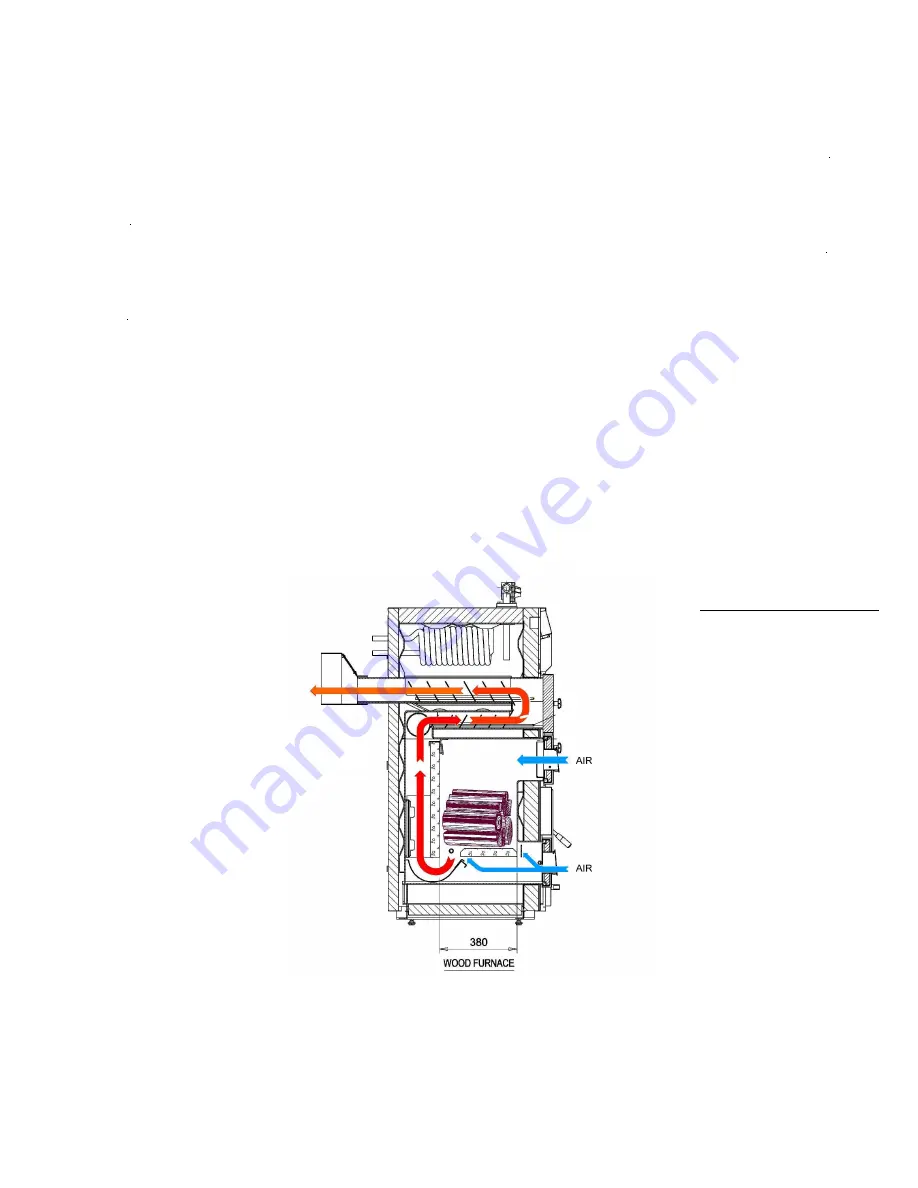

Cleaning the wood side is done from the front of the boiler. Most important is to keep

surfaces behind the cleaning hatch (nr. 1, figure 4) clean. The fire surfaces can be cleaned

boiler’s fire surfaces is important to keep the high efficiency.

Remove combustion residue through fire management hatch. Notice! The cleanness of the

This is normally achieved by running the oil/gas burner or by using the heat stored in the thermal store.

A clear sign of the boiler being under the temperature is that the wood does not light up properly, there

is an excessive amount of smoke, the flue does not draw and the fire box surfaces condensate.

When using wood, it is paramount that the boiler has a base heat of >65°C.

IMPORTANT

WWW.JASPI.UK