3

GENERAL INSTALLATION INSTRUCTIONS

-

Install the boiler in an upright position on an incombustible surface in a dry boiler room.

-

Observe sufficient installation and maintenance space around the boiler.

-

Boiler connections to the network are done so that the piping is not strained.

-

Install necessary lock valves in the network for maintenance purposes.

-

During the network pressure test the boiler pressure must not exceed 1,5 bar.

-

After filling, the pipe connections and sealing are carefully checked to avoid damage to the

boiler and electric appliances from a possible leak.

-

The free combustion air opening, that is lead to the boiler room, should be at least the size

of the chimney aperture (150 mm x 150 mm).

-

The boiler is connected to the chimney with the chimney extension liner (standard

equipment). Joints must be carefully compressed with mineral wool, fibre glass braid or

equivalent to avoid the weakening of traction.

-

The distance between the boiler and the duct can be up to several metres. In that case the

connecting pipe should be in a horizontal or rather ascending position and the cross-section

must conform to chimney recommendations. The pipe should be isolated and the joints

sealed. Possibility to sweep the chimney should also be ensured.

INSTALLATION

Expansion system

Coated expansion container system

device) 1.5 bar safety valve whose blasting output should correspond to the amount of (water)

The safety valve is installed unclamped to the boiler’s boiling aggregate. The valve’s exhaust

pipe should not be reduced from it’s nominal size and it should be directed thus, that the

discharged vapor does not damage people or property.

The active volume of the coated expansion boiler should be at least 5% of the facility’s total

water quantity. In practice it should be dimensioned according to at least 7%.

Open expansion container system

On top of the boiler an unlocked sleeve pipe should be led to the expansion container. The

overflow pipe should be mounted descending. The vapor discharge pipe should be

continuously ascending and it’s pate directed thus, that it does not damage people or

property.

valve is mounted between the cold and hot water aggregates.

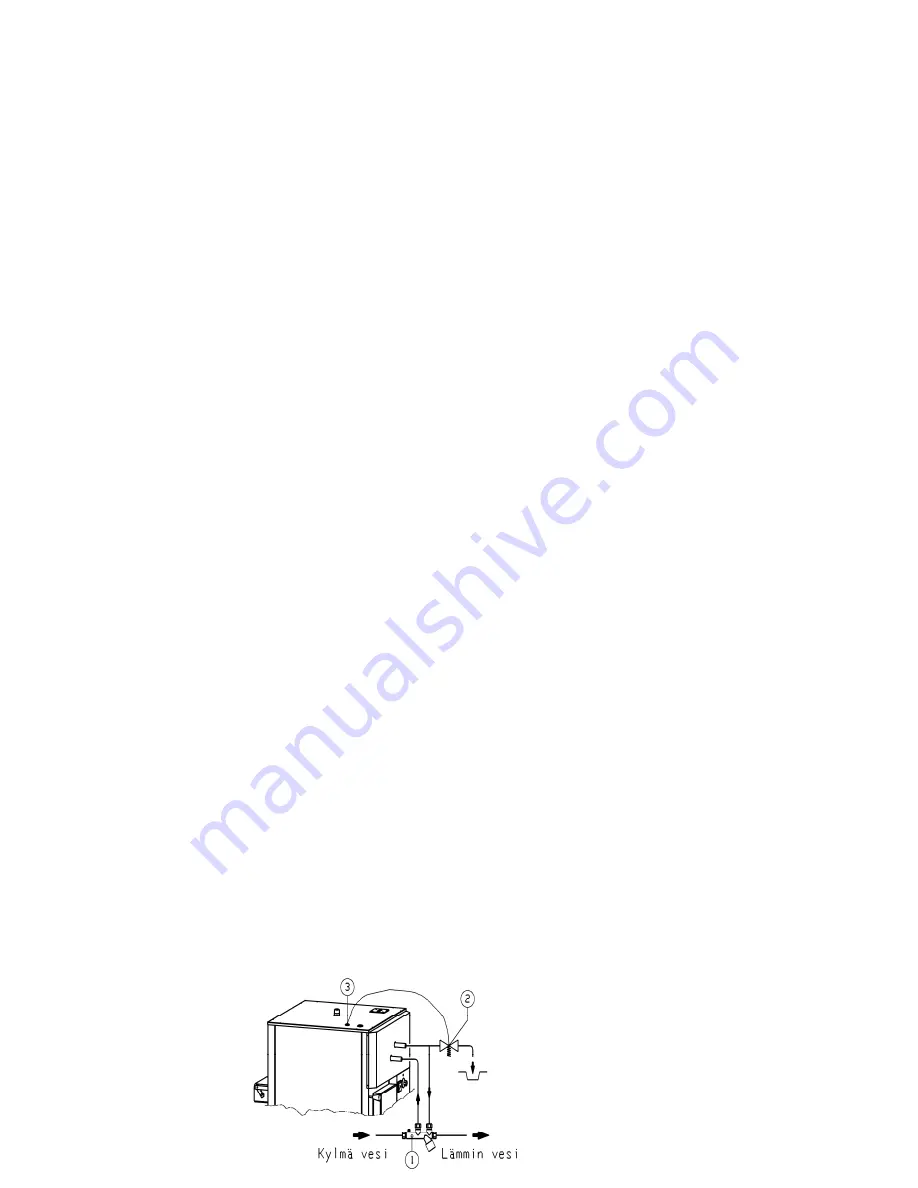

A boiling prevention valve must be connected to the hot water coil to block overheating when

wood is being burnt. Valve connection guidelines are shown in figure 2.

Figure 2. Connecting the boiling prevention valve (e.g. Jäspi-TSK) to the driving water coil.

1. Valve group

2. Boiling prevention valve

3. Sensor

vapor that is produced at maximum output

. Use of two safety valves is recommended.

a closing valve, a backlash valve and a 10 bar safety valve. The hot water thermostatic mixing

The cold water pipe connected to the DHW coil must equipped be with a valve group, including

Domestic hot water system (DHW)

On top of the boiler in the boiling connection there must be a reliable (without a clamping

container’s minimum volume must be 7% of the facility’s total water quantity. The container’s

WWW.JASPI.UK