CHAPTER 2. DISASSEMBLY OF MAJOR COMPONENTS

17

2

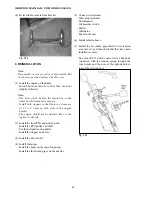

1. GENERAL PRECAUTIONS FOR SEPARATION AND REINSTALLATION

1.1. BEFORE OPERATION

a. Always be safety-conscious in selecting clothes

to wear and suitable tools to use.

b. Before disassembly, be sure that you familiarize

yourself with the assembled condition for

subsequent reference in reassembly.

c. Keep parts and tools in proper order during

operations.

d. When servicing electrically live parts, be sure to

disconnect the negative battery terminal.

e. To prevent oil or water leaks, use the liquid

gasket as required.

f. When reassembling disassembled parts, discard

used gaskets, O-rings, or oil seals and install new

ones.

g. When lifting up only the front or rear part of the

tractor, be sure to wedge the grounded wheels.

h. When the tractor is jacked up, be sure to support

the entire tractor with something like a stand.

Lifting it up with a jack only is a dangerously

unstable procedure.

i. When replacing parts, use authorized, genuine

ISEKI parts only. ISEKI assumes no responsibility

for accidents, operating problems or dam-age

caused by the use of imitation parts. Also, the use

of unauthorized parts will result in relatively poor

machine performance.

1.2. PRECAUTIONS TO BE FOLLOWED WHEN

INSTALLING COMMON PARTS

a. Roller or ball bearings

• When a bearing is fitted in by the outer race, use an

installer which is specially designed to push only the

outer race and vice versa.

• The installer must be designed to install the bearing

on the shaft in a parallel position.

•When installing a bearing which appears the same on

both sides, install it so that the face which has the

identification number faces in a direction for easy

visual identification. All the bearings which are to be

installed in the transmission case should be placed so

that their identification number faces outward.

• If a shaft or a hole where a bearing is to be installed

has a stopper, the bearing should be pushed in

completely until it is seated against the stopper.

• Installed bearings should turn smoothly.

b. Oil seals

• Oil seal installer should be designed so as not to

deform the oil seals.

• During installation, be careful not to damage the lips,

and assure that it is pushed in parallel to the shaft or

hole.

• When oil seals are installed, there should be no

turnover of the lips nor dislocation of the springs.

• When a multi-lip seal is installed, the grooves

between lips should be filled with grease, not

adhesive.

• Use a lithium-based grease.

• There should be no oil or water leaks through the

installed soil seals.

CHAPTER 2. DISASSEMBLY OF MAJOR COMPONENTS

Содержание SXG323

Страница 1: ...LAWN MOWERS MOWER DECKS COLLECTORS SCMB48 SCMA54 SBC550X 600X ...

Страница 5: ......

Страница 11: ...SERVICE MANUAL FOR SXG323 326 10 ...

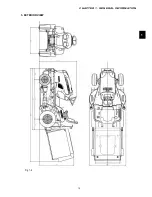

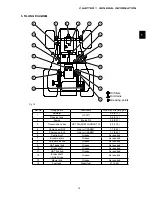

Страница 14: ...CHAPTER 1 GENERAL INFORMATION 13 1 3 EXTERIOR VIEW Fig 1 4 ...

Страница 17: ...SERVICE MANUAL FOR SXG323 326 16 ...

Страница 33: ...SERVICE MANUAL FOR SXG323 326 32 ...

Страница 35: ...SERVICE MANUAL FOR SXG323 326 34 1 2 PERFORMANCE CURVES 1 SXG326 E3112 G07 Fig 4 1 2 SXG323 E3112 G06 Fig 4 2 ...

Страница 51: ...SERVICE MANUAL FOR SXG323 326 50 3 3 CYLINDER BLOCK 3 3 1 EXPLODED VIEW Fig 4 55 ...

Страница 67: ...SERVICE MANUAL FOR SXG323 326 66 ...

Страница 70: ...CHAPTER 5 LUBRICATION SYSTEM 69 5 1 4 EXPLODED VIEW OF OIL PUMP Fig 5 4 ...

Страница 73: ...SERVICE MANUAL FOR SXG323 326 72 ...

Страница 89: ...SERVICE MANUAL FOR SXG323 326 88 42 3 33 Fig 8 3 2 2 7 2 6 3 TYPE Fig 8 4 ...

Страница 93: ...SERVICE MANUAL FOR SXG323 326 92 ...

Страница 97: ...SERVICE MANUAL FOR SXG323 326 96 2 OPERATING DIAGRAM OF HST Fig 10 2 ...

Страница 99: ...SERVICE MANUAL FOR SXG323 326 98 Fig 10 5 Fig 10 6 ...

Страница 100: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 99 10 Fig 10 7 ...

Страница 101: ...SERVICE MANUAL FOR SXG323 326 100 Fig 10 8 4 DISASSEMBLY AND REASSEMBLY ...

Страница 102: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 101 10 4 3 ...

Страница 103: ...SERVICE MANUAL FOR SXG323 326 102 ...

Страница 107: ...SERVICE MANUAL FOR SXG323 326 106 4 5 CRITERIA FOR REPLACING WORN PARTS ...

Страница 117: ...SERVICE MANUAL FOR SXG323 326 116 ...

Страница 124: ...CHAPTER 12 POWER STEERING SYSTEM 123 12 3 MAJOR TROUBLES AND CAUSES AND COUNTERMEASURES ...

Страница 125: ...SERVICE MANUAL FOR SXG323 326 124 ...

Страница 126: ...CHAPTER 12 POWER STEERING SYSTEM 125 12 ...

Страница 127: ...SERVICE MANUAL FOR SXG323 326 126 ...

Страница 129: ...SERVICE MANUAL FOR SXG323 326 128 3 ALL TYPE Engine Fig 13 7 Fig 13 8 Fig 13 10 Fig 13 9 Fig 13 11 ...

Страница 130: ...CHAPTER 13 ELECTRICAL ACCESSORIES 129 13 2 WIRING DIAGRAM E TYPE Fig 13 12 ...

Страница 131: ...SERVICE MANUAL FOR SXG323 326 130 3 WIRING DIAGRAM GE TYPE Fig 13 13 ...

Страница 132: ...CHAPTER 13 ELECTRICAL ACCESSORIES 131 13 Fig 13 14 4 STARTER ...

Страница 140: ...CHAPTER 13 ELECTRICAL ACCESSORIES 139 13 Fig 13 48 Fig 13 47 ...

Страница 149: ......

Страница 151: ...SERVICE MANUAL FOR SXG323 326 4 ...

Страница 152: ...CHAPTER 1 FOR SAFETY LABELS 5 1 SAFETY LABELS SCMB48 54 CHAPTER 1 FOR SAFETY LABELS ...

Страница 163: ...SERVICE MANUAL FOR SXG323 326 16 ...

Страница 171: ...SERVICE MANUAL FOR SXG323 326 24 ...

Страница 173: ...SERVICE MANUAL FOR SXG323 326 26 3 Gear box left hand ...

Страница 175: ...SERVICE MANUAL FOR SXG323 326 28 SCMB48 54 Front Belt and Belt tension Blade and Blade hub ...

Страница 183: ......

Страница 185: ...SERVICE MANUAL FOR SXG323 326 4 ...

Страница 188: ...CHAPTER 2 SPECIFICATIONS 7 2 SPECIFICATIONS CHAPTER 2 SPECIFICATIONS ...

Страница 189: ...SERVICE MANUAL FOR SXG323 326 8 ...

Страница 191: ...SERVICE MANUAL FOR SXG323 326 10 ...

Страница 195: ...SERVICE MANUAL FOR SXG323 326 14 ...

Страница 214: ...CHAPTER 7 ASSEMBLY INSTRUCTION 33 7 Hydraulic hose allocation How to allocate pipes of CONTROL VALVE ...

Страница 227: ...SERVICE MANUAL FOR SXG323 326 46 ...

Страница 229: ...SERVICE MANUAL FOR SXG323 326 48 ...