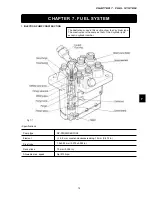

CHAPTER 7. FUEL SYSTEM

83

7

3.5 - 4.0 kgf

兟

m

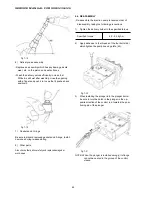

When a nozzle is found functioning poorly through spray

test, wash it. If its original function is not restored by

washing, replace it.

兟

Nozzle washing

First wash the nozzle in clean gasoline, and then wash it

again in clean diesel fuel before assembling it.

If the nozzle is seized, soak it in cleaning liquid after

washing. Then wash it again.

3.4. INSTALLATION OF INJECTION NOZZLES AND

HOLDERS

兟

Before installation, wash all parts in clean diesel fuel

or cleansing oil.

兟

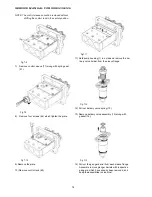

Put the adjusting shim, spring, pressure pin, and dis-

tance piece on the nozzle holder body in this order.

Lastly place the nozzle assembly and retain with the

retaining nut.

兟

Nozzle replacement

Replace the assembly of the needle valve and nozzle

body.

Before installing a new nozzle, move the needle valve

sufficiently in the nozzle body in clean diesel fuel

warmed up at 50 - 60°C (122 - 140°F) to remove the

anti-corrosive completely.

兟

Needle valve sliding

Move the needle valve in and out of the nozzle body

several times in clean diesel fuel to make sure of its

smooth movement.

Slant the nozzle body by about 60°, pull out the needle

valve by about one-third of its length, and release it.

When it comes down smoothly, it is normal. Perform

three tests with the needle valve turned by 120°at each

test.

If the needle valve does not move smoothly, replace the

assembly of the needle valve and nozzle holder.

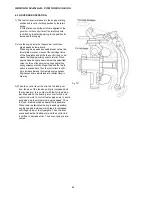

Fig. 7-28

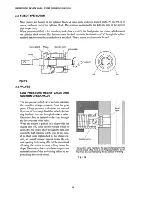

NOTE: When installing the pressure pin and distance

piece, pay attention to their directions.

兟

Hold the nozzle holder body in a vise and tighten the

retaining nut to the specified torque.

Specified torque

Incorrect tightening torque will lead to fuel leakage or

nozzle seizure.

兟

Remove the assembly from the vise and install a new

washer, the packing ring, and nut. (Be sure to discard

the removed washer and install a new one.)

兟

Check each assembly on a nozzle tester for spraying,

valve-opening pressure, etc.

Valve-opening pressure should be adjusted with an

adjusting shim.

3.5. INSTALLATION OF INJECTION NOULES AND

HOLDERS

兟

Install the nozzle gasket into the cylinder head.

兟

Screw in the retaining nut by hand.

兟

Tighten the retaining nut to the specified torque, using

a box wrench [21 mm (0.83 in.)].

Specified torque

4

䢯

5 kgf

兟

m

兟

When using an air tool to tighten the nut, make its

tightening speed as slow as possible.

Содержание SXG323

Страница 1: ...LAWN MOWERS MOWER DECKS COLLECTORS SCMB48 SCMA54 SBC550X 600X ...

Страница 5: ......

Страница 11: ...SERVICE MANUAL FOR SXG323 326 10 ...

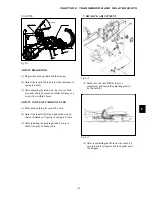

Страница 14: ...CHAPTER 1 GENERAL INFORMATION 13 1 3 EXTERIOR VIEW Fig 1 4 ...

Страница 17: ...SERVICE MANUAL FOR SXG323 326 16 ...

Страница 33: ...SERVICE MANUAL FOR SXG323 326 32 ...

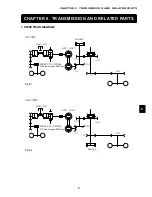

Страница 35: ...SERVICE MANUAL FOR SXG323 326 34 1 2 PERFORMANCE CURVES 1 SXG326 E3112 G07 Fig 4 1 2 SXG323 E3112 G06 Fig 4 2 ...

Страница 51: ...SERVICE MANUAL FOR SXG323 326 50 3 3 CYLINDER BLOCK 3 3 1 EXPLODED VIEW Fig 4 55 ...

Страница 67: ...SERVICE MANUAL FOR SXG323 326 66 ...

Страница 70: ...CHAPTER 5 LUBRICATION SYSTEM 69 5 1 4 EXPLODED VIEW OF OIL PUMP Fig 5 4 ...

Страница 73: ...SERVICE MANUAL FOR SXG323 326 72 ...

Страница 89: ...SERVICE MANUAL FOR SXG323 326 88 42 3 33 Fig 8 3 2 2 7 2 6 3 TYPE Fig 8 4 ...

Страница 93: ...SERVICE MANUAL FOR SXG323 326 92 ...

Страница 97: ...SERVICE MANUAL FOR SXG323 326 96 2 OPERATING DIAGRAM OF HST Fig 10 2 ...

Страница 99: ...SERVICE MANUAL FOR SXG323 326 98 Fig 10 5 Fig 10 6 ...

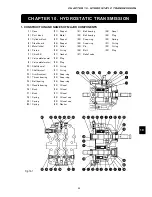

Страница 100: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 99 10 Fig 10 7 ...

Страница 101: ...SERVICE MANUAL FOR SXG323 326 100 Fig 10 8 4 DISASSEMBLY AND REASSEMBLY ...

Страница 102: ...CHAPTER 10 HYDROSTATIC TRANSMISSION 101 10 4 3 ...

Страница 103: ...SERVICE MANUAL FOR SXG323 326 102 ...

Страница 107: ...SERVICE MANUAL FOR SXG323 326 106 4 5 CRITERIA FOR REPLACING WORN PARTS ...

Страница 117: ...SERVICE MANUAL FOR SXG323 326 116 ...

Страница 124: ...CHAPTER 12 POWER STEERING SYSTEM 123 12 3 MAJOR TROUBLES AND CAUSES AND COUNTERMEASURES ...

Страница 125: ...SERVICE MANUAL FOR SXG323 326 124 ...

Страница 126: ...CHAPTER 12 POWER STEERING SYSTEM 125 12 ...

Страница 127: ...SERVICE MANUAL FOR SXG323 326 126 ...

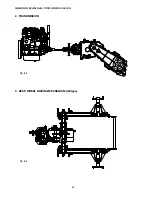

Страница 129: ...SERVICE MANUAL FOR SXG323 326 128 3 ALL TYPE Engine Fig 13 7 Fig 13 8 Fig 13 10 Fig 13 9 Fig 13 11 ...

Страница 130: ...CHAPTER 13 ELECTRICAL ACCESSORIES 129 13 2 WIRING DIAGRAM E TYPE Fig 13 12 ...

Страница 131: ...SERVICE MANUAL FOR SXG323 326 130 3 WIRING DIAGRAM GE TYPE Fig 13 13 ...

Страница 132: ...CHAPTER 13 ELECTRICAL ACCESSORIES 131 13 Fig 13 14 4 STARTER ...

Страница 140: ...CHAPTER 13 ELECTRICAL ACCESSORIES 139 13 Fig 13 48 Fig 13 47 ...

Страница 149: ......

Страница 151: ...SERVICE MANUAL FOR SXG323 326 4 ...

Страница 152: ...CHAPTER 1 FOR SAFETY LABELS 5 1 SAFETY LABELS SCMB48 54 CHAPTER 1 FOR SAFETY LABELS ...

Страница 163: ...SERVICE MANUAL FOR SXG323 326 16 ...

Страница 171: ...SERVICE MANUAL FOR SXG323 326 24 ...

Страница 173: ...SERVICE MANUAL FOR SXG323 326 26 3 Gear box left hand ...

Страница 175: ...SERVICE MANUAL FOR SXG323 326 28 SCMB48 54 Front Belt and Belt tension Blade and Blade hub ...

Страница 183: ......

Страница 185: ...SERVICE MANUAL FOR SXG323 326 4 ...

Страница 188: ...CHAPTER 2 SPECIFICATIONS 7 2 SPECIFICATIONS CHAPTER 2 SPECIFICATIONS ...

Страница 189: ...SERVICE MANUAL FOR SXG323 326 8 ...

Страница 191: ...SERVICE MANUAL FOR SXG323 326 10 ...

Страница 195: ...SERVICE MANUAL FOR SXG323 326 14 ...

Страница 214: ...CHAPTER 7 ASSEMBLY INSTRUCTION 33 7 Hydraulic hose allocation How to allocate pipes of CONTROL VALVE ...

Страница 227: ...SERVICE MANUAL FOR SXG323 326 46 ...

Страница 229: ...SERVICE MANUAL FOR SXG323 326 48 ...