XSP UNITS ONLY!

Problem: ES-2000XSP/ES-2000XSP-PH Machine will not run. Wash motor will run if wash relay is depressed manual-

ly (nothing else works).

1. Open detergent safety switch. With door closed and detergent capsule in place, measure for voltage between the

WHITE/BLACK and ORANGE/BLUE wires at the safety switch. If it reads 115 volts, replace switch.

2. Faulty dispenser safety switch relay. Measure between the WHITE wire on terminal 4 and the WHITE wire on terminal 7 of

the dispenser safety switch relay. If it reads 115 volts, replace relay.

Problem: ES-4000XSP/ES-4000XSP-PH Machine will not run. Wash motor will run if wash relay is depressed manual-

ly (nothing else works).

1. Open side door switch. With door closed, measure voltage between the BLUE wire and WHITE/BLACK wire on the door

switch. If it reads 115 volts, replace switch.

2. Faulty side door safety switch relay. Measure between the BLACK wires on terminals 6 and 9 of the relay. If it reads 115

volts, replace relay. Measure between the WHITE/BLACK wire on terminal 4 and ORANGE/WHITE wire on terminal 7 of the

relay. If it reads 115 volts, replace relay.

Problem: Solid product feeds continuously (Detergent or Rinse Aid).

1. Faulty solenoid valve. Replace diaphragm, clean valve.

2. Faulty detergent or rinse aid microswitch. Replace appropriate microswitch.

Problem: Excessive solid product consumption.

1. Cam timer not adjusted. Shorten dispense time on cam timer.

2. Feed water pressure too high. Reduce pressure at primary and secondary regulators.

3. Machine wash tank filled too high. Adjust fill cam time to reduce fill height. Water level in tank should be near the lower ring

marking on the drain stopper.

4. Extremely high source water temperature. If over 170°F, turn down the water heater.

Problem: Detergent reservoir plugging frequently.

1. Dispenser flush time too low. Increase the flush time on the cam timer (cam 8).

2. Hard water is depositing scale in dispenser. Increase the amount of detergent to tie up water hardness. Install water soft-

ener in account.

Problem: 1/4” water distribution manifold leaks.

1. Tubing not secured properly. Pull out on tubing to seal connection. The internal o-ring seals the tube when tubing is pulled

out away from the manifold.

2. Internal o-ring or red plastic sleeve is damaged. Replace manifold.

3. End of tubing not cut square. Remove tubing and recut the tube to make a clean, square end.

ES-2000 & ES-4000 Series Installation/Operation Manual 7610-011-35-10

Issued: 10-29-2007 Revised: N/A

SECTION 4: TROUBLESHOOTING

XSP COMMON PROBLEMS

30

Содержание ECOLAB ES-2000

Страница 2: ......

Страница 7: ...1 SECTION 1 SPECIFICATION INFORMATION ...

Страница 17: ...11 SECTION 2 INSTALLATION OPERATION INSTRUCTIONS ...

Страница 29: ...23 SECTION 3 PREVENTATIVE MAINTENANCE ...

Страница 31: ...25 SECTION 4 TROUBLESHOOTING ...

Страница 37: ...31 SECTION 5 SERVICE PROCEDURES ...

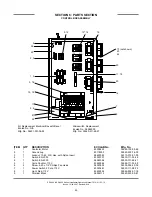

Страница 44: ...38 SECTION 6 PARTS SECTION ...

Страница 85: ...79 SECTION 7 ELECTRICAL SCHEMATICS ...