TIMER FOR MODEL 100 DISHWASHERS

General Description

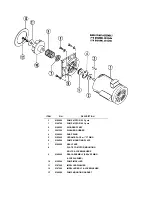

The timer is a self-contained (frame-mounted) timer of the repeating cycle type. It is mounted on

the control panel of Jackson Automatic Dishwashing machines, to control the automatic functions of

these machines. It consists of a clock motor which operates on

60 cycle AC, 220 VAC. In addition to the

clock motor, the timer also contains a driven cam arrangement which operates three micro switches.

Principle of Operation

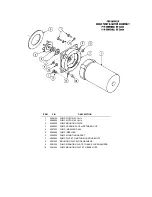

The timer controls various operations of the automatic washers as per wiring diagram for each

machine, however, the timing cycle and the micro switches are the same for each model. The time for

ONE COMPLETE REVOLUTION of the cam shaft is approximately 120 seconds, allowing two wash

and two rinse operations for each complete revolution of the cam shaft. The micro switch nearest the

timer motor is the hold circuit and uses both the NO and NC contacts. The middle micro switch controls

the wash and uses the NO contact. The micro switch farthest away from the timer motor controls the

rinse and uses just the NC contact.

Service Instructions

CAUTION: ALWAYS REMOVE THE POWER TO THE MACHINE BEFORE WORKING ON THE

CONTROL PANEL OR WHILE SERVICING THE COMPONENTS ON THE SWITCH

PANEL. ALL ELECTRICAL CHECKS SHOULD BE MADE BY QUALI-FIED PERSONNEL.

Timer operation can be observed after removing the control panel from the control box by

loosening the four screws holding it. Hang the control panel using the two right hand screws with the

back side of the panel outward.

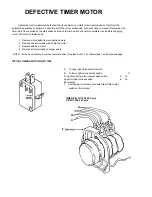

If it is determined that the timer is defective, it is recommended that a new timer be in-

stalled. However, limited field maintenance can be accomplished as follows:

A frozen contact on a micro switch will be indicated by one function being executed all the time or

the absence of a click when the switch arm is actuated. The micro switch

is replaced by:

1. Remove all wires from the timer, properly tag them to assure proper replacement.

2. Remove the two screws which hold the timer to the control panel.

3. One screw holds the micro switches, cams and actuating arms in the frame. This screw

is seen on the side opposite the motor. Remove this screw. NOTE: Be sure to note which

cam goes with which micro switch. Cam nearest timer motor has % raised, cam center,

larger depressed areas, cam farthest from timer motor, smallest depressed areas.

4. The unit can now be taken apart and the defective micro switch replaced.

5. Reassemble. NOTE: The flanges on the cams are such that they only mesh in one

direction. The shorter flange on the cams always points toward the drive motor.

The timers cam drive system is equipped with a clutch to enable one to view the operations of the

cams and micro switches. Remove power to machine BEFORE touching timer. Rotate

cams by turning

with fingers; cams will turn in one direction only. Do not force them. As cams actuate switches, listen

for the click of the switch or test the switches with an ohmmeter.

10

Содержание 100 B/PRB

Страница 6: ......

Страница 26: ......

Страница 46: ...45 BOOSTER TANK HEATER ELEMENT P N 0060500 WASH TANK HEATER ELEMENT P N 0058000...