EN

4. Operation instructions

1. Turn the machine “ON” using the main power switch. Open the valve of the gas bottle

and adjust the gas flow on the pressure regulator.

2. Select the diameter of MIG torch nozzle according to the welding wire diameter. Set

up the parameters the welding mode and the cooling mode.

- If you choose MMA welding mode(with or without VRD function) adjust the MMA weld

-

ing parameters .

- If you choose TIG welding mode, adjust the TIG welding parameters.

- If you choose MIG/MAG welding mode, adjust the welding parameters on the control

panel of wire feeder.

3. According to thickness and process of workpiece, adjust the voltage and the current.

Select the “synergy” or “manual” function by pressing the “K” button on the control

panel of wire feeder.

4. Inductance adjustment can change the ARC strenght.

5. Begin to weld by pressing.

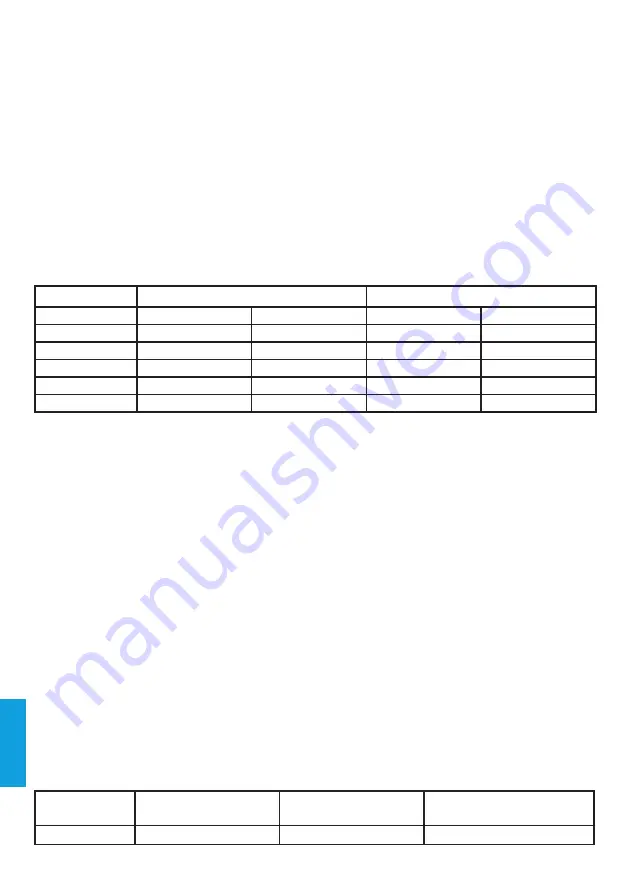

Wireφ(mm)

Short circuit transition

Granular transition

Current(A)

Voltage (V)

Current(A)

Voltage (V)

0.6

40~70

17~19

160~400

25~38

0.8

60~100

18~19

200~500

26~40

1.0

80~120

18~21

200~600

27~40

1.2

100~150

19~23

300~700

80~120

1.6

140~200

20~24

500~800

32~44

Welding

mode

Thin wire

C0

2

welding

Thick wire

C0

2

welding

Thick wire, big current

C0

2

welding

C0

2

(l/min)

5-15

15-25

25-50

4.1 Setting the welding current

The selection of welding current ,voltage and ARC will influence the stability, welding

quality and the productivity during the welding process. In order to keep a good weld

-

ing quality, the welding current should match the voltage and the ARC well. Select the

wire diameter according to the globular transfer and the production requirement.

Refer to the below list, choose the common welding current, ARC and voltage.

-The option of the welding speed

The welding quality and productivity should be taken into consideration for the option

of welding speed. In case that the welding speed increases, it weakens the protection

efficiency and speeds up the cooling process. As a consequence, it is not optimal for

the seaming. In the event that the speed is too slow, the work piece will be easily dam

-

aged, and the seaming is not ideal. In practical operation, the welding speed should

not exceed 30m/hour.

-The length of wire stretching out

The length of wire stretching out the nozzle should be appropriate. The increase of the

length of wire stretching out of the nozzle can improve the productivity, but if it is too

long, excessive spatter will occur in the welding process. Generally, the length of wire

stretching out the nozzle should be 10 times as the welding wire diameter.

-The setting of the C0

2

flow volume

The protection efficiency is the primary consideration. Besides, inner-angle welding has

better protection efficiency than external-angel welding. For the main parameter, refer

to the following figure.

25

24

Содержание MIG 520 COOLPULSE

Страница 14: ...HU 14...

Страница 16: ...EN INDEX INTRODUCTION 3 MAIN PARAMETERS 4 WARNING 5 INSTALLATION 6 7 OPERATION 8 12 CAUTIONS MAINTENANCE 13 16...

Страница 28: ......

Страница 31: ......

Страница 32: ...www iweld hu...