Page 38

Operation and Maintenance Instructions

Envistar Top 04-21

DSET.181201.00.EN

Continuous product development may give rise to specification changes without notice.

Cleaning

The counter-flow exchangers are designed to prevent dirt and deposits from com-

ing into contact with the heat transfer surfaces. Most of the particles in the air will

pass through the counter-flow exchanger. The main risk for fouling of the counter-

flow exchanger comes from slow-moving substances that condense on the sur-

faces, and also from fibres from tumble dryers, for instance.

The recommended way to clean the counter-flow exchanger is by flushing with

hot water, if necessary adding some mild detergent. The counter-flow exchanger

is equipped with a drip tray that is used for collecting the water used for flushing.

Inspect the waste outlet and water trap before flushing.

NB:

High pressure flushing must not be directed at the fins.

Be careful in order to ensure that the fins do not become deformed or

break.

At operating temperatures below 0°C, the counter-flow exchanger must be dry

before commissioning.

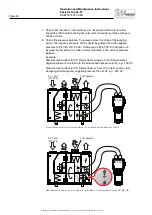

Functional description, defrost and bypass function (ODS) (ATMM-XP/NP)

Under certain operating conditions, frost and ice may form on the extract air side

of the counter-flow exchanger. In order to optimise heat recovery, there is a built-in

defrost function. This is based on the principle that the defrost function is engaged

when the pressure drop over the extract air side of the counter-flow exchange

exceeds a certain value.

Defrosting takes place through the regulation of dampers on the outdoor air side of

the counter-flow exchanger. The dampers have separate damper motors that are

controlled by a defrost program. Damper control means that there are a number of

different combinations of damper positions, for instance that one of the dampers

can be partly open while another is closed and the third damper is fully open.

During full heat recovery and when the unit is switched off, the dampers should be

fully open (bypass damper closed). When there is a risk of frost, the dampers can

be in different positions.

The defrost and bypass function is preset at the factory and any adjustments must

be performed by IV Produkt.

Functional description, frosting function (BYP) (ATMM-NP)

Under certain operating conditions, frost and ice may build-up on the extract air

side of the plate heat exchanger. In order to optimise heat recovery, and avoid

freezing, there is a built-in frosting function. The principle is based on the frosting

function starting when the temperature of the exhaust air side’s coldest surface

falls below a certain value.

The freezing process is prevented by reducing heat recovery gradually through

regulating dampers on the heat exchanger’s exhaust air side. The heat recovery

damper closes and the bypass damper opens. In this way, the exhaust air

temperature is increased and freezing is avoided.

During full heat recovery and when the unit is switched off, the dampers should be

fully open (bypass damper closed).

The frosting and bypass functions are preset at the factory and any adjustments

may only be performed by IV Produkt.