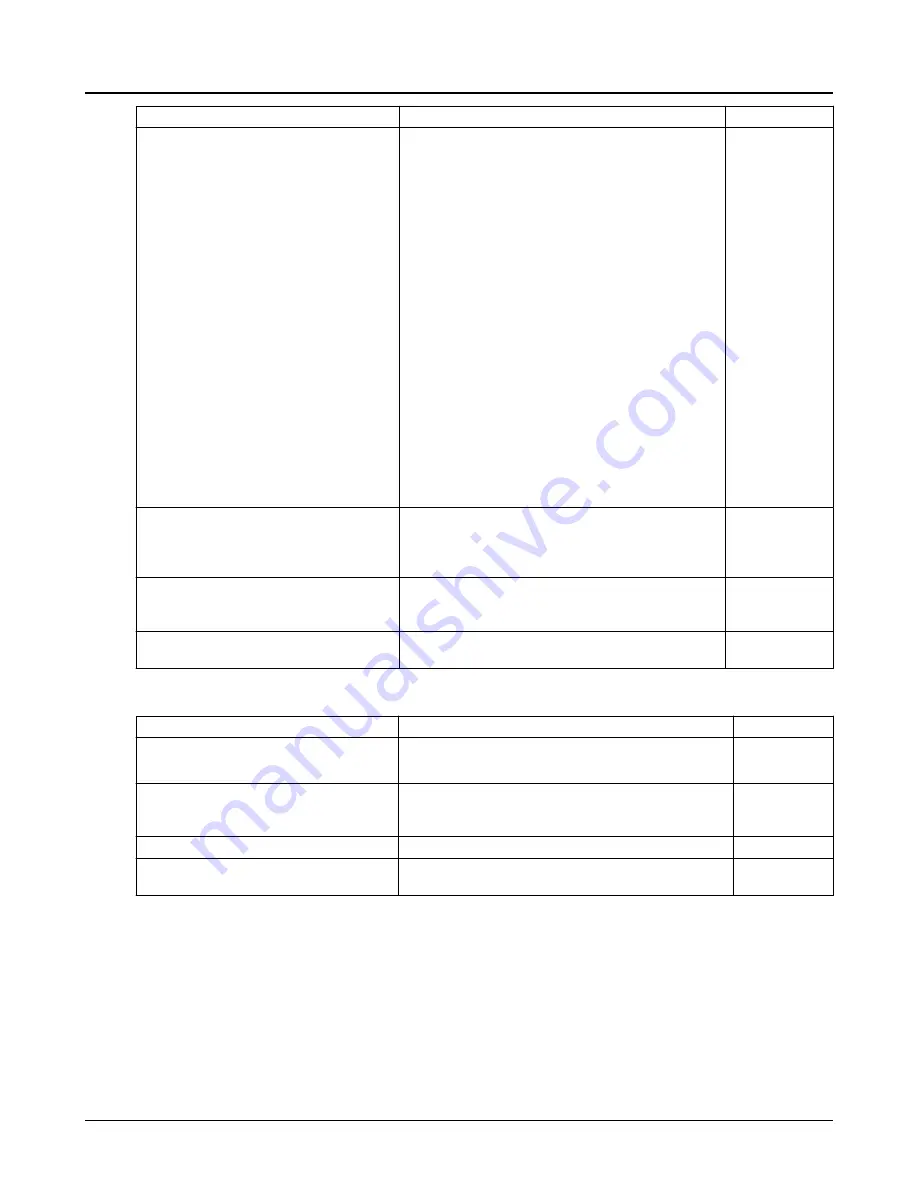

Check

Explanation/comment

Checked

It is recommended that a commissioning

(temporary) suction strainer be used.

After commissioning it is recommended an

operating (permanent) suction strainer be

used.

Check that the strainer has at least three

times the area of the suction piping.

Check the location of the suction strainer is

at least 5 pipe diameters from the suction

nozzle.

Continuously monitor the pressure drop

across the suction strainer.

Limit the pressure drop across the strainer

to 68.9 kPa | 10 psi, or the vapor pressure

of the pumped fluid, or the resulting NPSHr

is not adequate.

After a period of time (24 hours minimum)

system flushing should be complete and

the commissioning (temporary) suction

strainer can be removed.

Suction strainers help to prevent debris from entering

the pump

Recommended commissioning (temporary) strainer

mesh size:

•

Viscosity≤100cP use 60 mesh

•

Viscosity>100cP use 40 mesh

•

Viscosity>300cP use 20 mesh

Recommended operating (permanent) strainer mesh

size:

•

Viscosity≤100cP use 40 mesh

•

Viscosity>100cP use 20 mesh

•

Viscosity>300cP use 12 mesh

If more than one pump operates from the

same liquid source, check that separate

suction-piping lines are used for each

pump.

This recommendation helps you to achieve a higher

pump performance and prevent vapor locking espe-

cially with specific gravity of liquid less than 0.60.

If necessary, make sure that the suction

piping includes a drain valve and that it is

correctly installed.

—

Assure adequate insulation is applied for

liquids with specific gravity less than 0.60.

To assure sufficient NPSHa.

Liquid source below the pump

Check

Explanation/comment

Checked

Make sure that the suction piping is free

from air pockets.

This helps to prevent the occurrence of air and cavita-

tion in the pump inlet.

Check that the suction piping slopes up-

wards from the liquid source to the pump

inlet.

—

Check that all joints are air-tight.

—

If the pump is not self-priming, check that a

device for priming the pump is installed.

Use a foot valve with a diameter that is at least equiva-

lent to the diameter of the suction piping.

4.6 Piping checklists

34

3620 i-FRAME API type BB2 single stage / ISO 13709 2nd Ed/API 11th Ed Installation, Operation, and Maintenance

Manual

Содержание GOULDS PUMPS i-FRAME 3620

Страница 2: ......