ITT Flygt recommends a preventive maintenance

program based on Intermediate and major Services at

regular intervals.

The time between Major Service could vary

considerably depending on operating conditions and

the need for a Major Service will be determine during

the regular Intermediate Services.

CARE AND MAINTENANCE

9

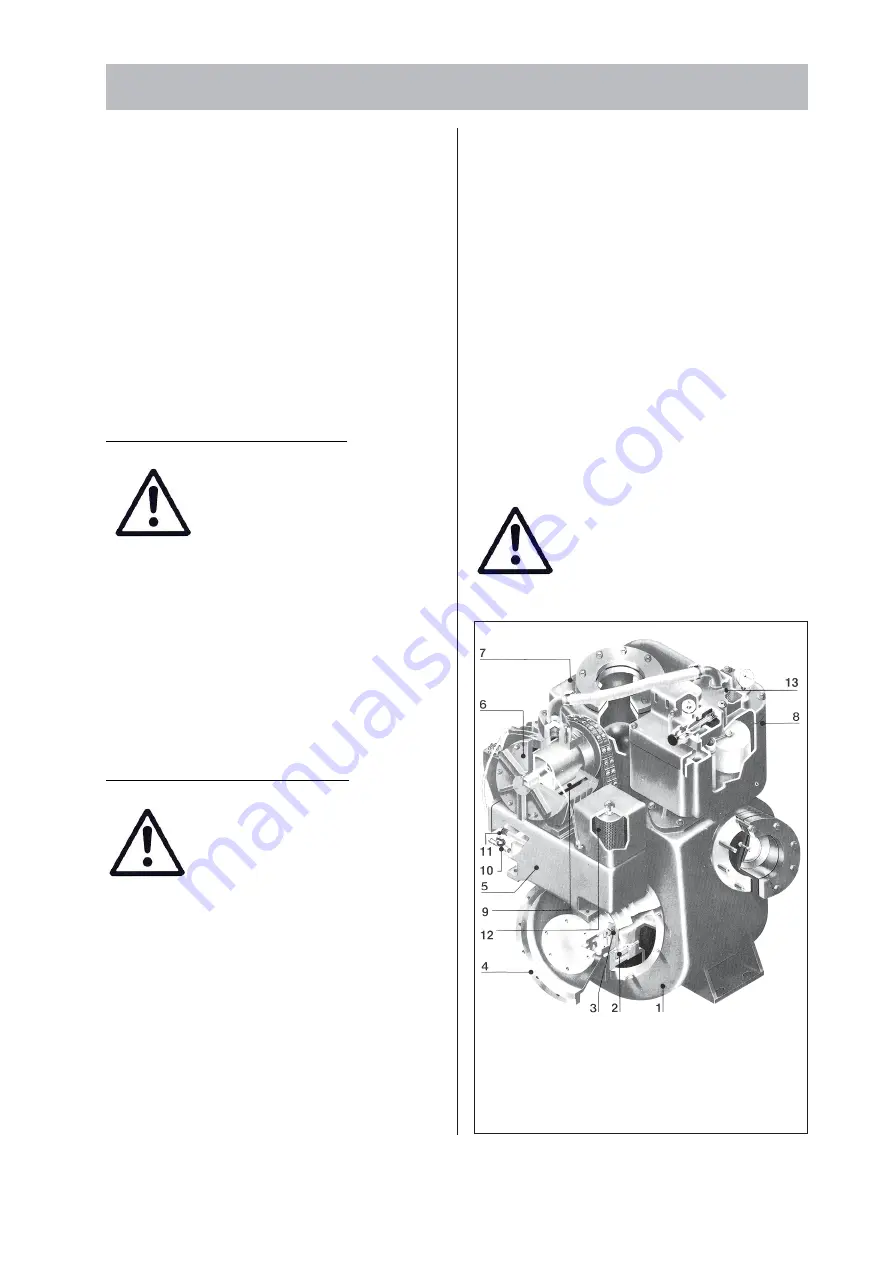

1) Pump casing

2) Impeller

3) Mechanical seal

4) Pump/motor coupling box

5) Vacuum pump oil tank

6) Complete vacuum pump

7) Outlet valve

4

8) Float to tank

9) Blade

10) Cock

11) Oil suction filter

12) Oil filter

13) Air filter

For routine maintenance of the diesel engine or

electric motor, follow the instructions in the manuals

provided.

Pumping units with diesel engine

During maintenance, ensure that

no metal or other conducting

object can short-circuit the

battery terminals with

consequent danger of explosion

of the battery.

If you have to isolate the battery,

first disconnect the negative pole

and then the positive pole (the

negative pole is earthed and if the

positive pole is disconnected

first, it increases the risk of

accidental short-circuit).

Pumping units with electric motor

During maintenance of the

pumping unit, isolate it by

disconnecting the socket from

the plug placed on the control

panel.

Inspection (version with oil vacuum

pump)

- Drain the condensate in the oil tank (Tab. 4,

part.10), through the cock at least once a day.

- For the suction pump use SAE 15W40 ENGINE

OIL.

- Every 1000 working hours wash oil suction filter

with gas/fuel oil (Tab. 4, part.11).

- Every 1000 working hours replace oil filter (Tab. 4,

part.12)

- Every 1000 working hours replace air filter (Tab. 4,

part.13)

Before starting work on the

pump make sure that it

cannot be started, even

accidentally.