11

MAINTENANCE

SCHEDULE:

Blow down control as follows when boiler is

in operation.

• Daily if operating pressure is above 15 psi.

• Weekly if operating pressure is below 15 psi.

• Remove head assembly and inspect water

side components annually.

Replace head

assembly if any of the internal components are

worn, corroded or damaged or if control no longer

operates properly.

• Inspect the float chamber and equalizing piping

annually.

Remove all sediment and debris.

Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist.

Replacement parts are available from your local

authorized McDonnell & Miller Distributor.

The use of parts or components other than those

manufactured by McDonnell & Miller will void all

warranties and may affect the units compliance with

listings or regulating agencies.

BLOW DOWN PROCEDURE:

When blowing down a control at pressure, the blow

down valves should be opened slowly.The piping

needs to be warmed up and stagnant water in the

drain piping needs to be pushed out. Suddenly

opening a blow down valve causes steam to

condense, which can create water hammer.

Damage to components can occur when water

hammer occurs due to improper blow down piping.

For these reasons, McDonnell & Miller recommends

a dual valve blow-down system for each control.

Blow down the control when the water in the boiler

is at its normal level and the burner is on.

NOTE:

Refer to page 2 for switch operating points.

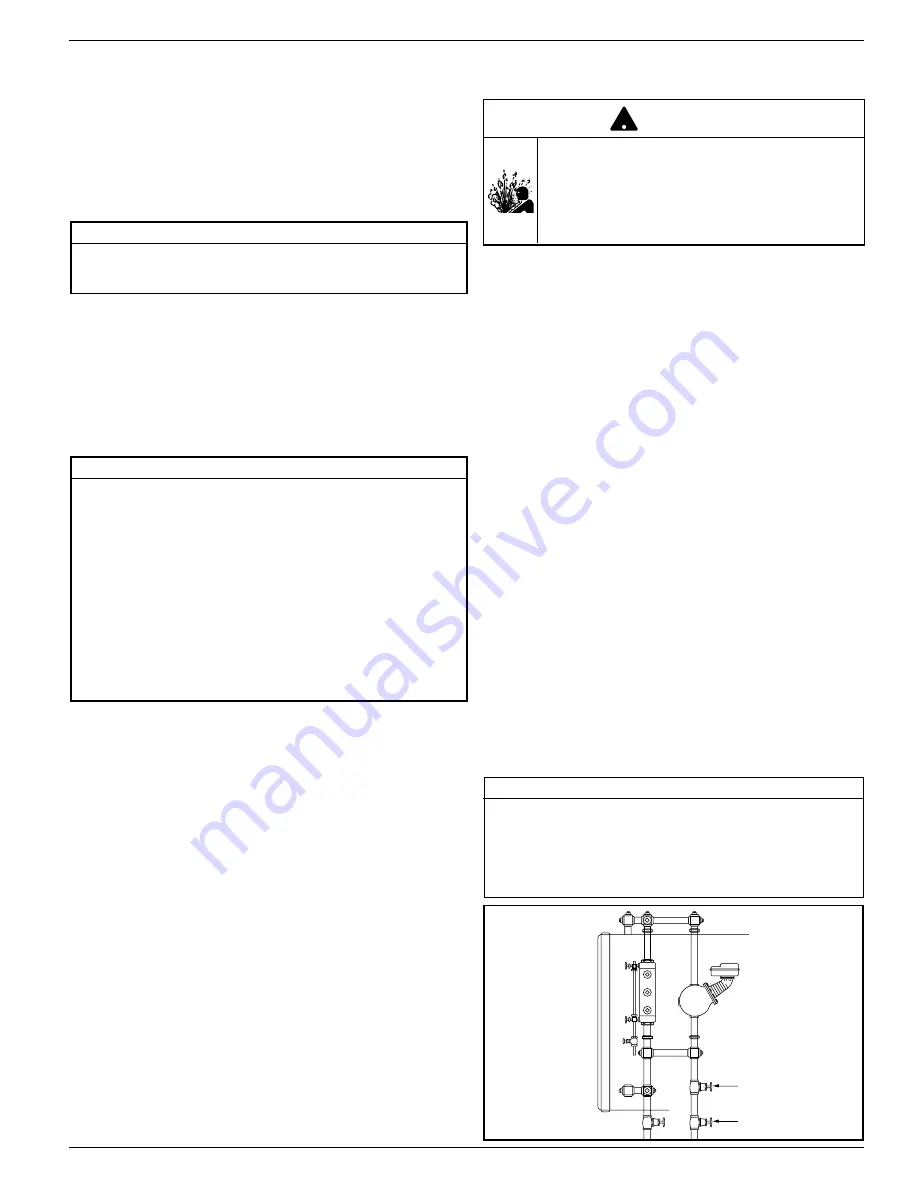

• Open upper valve (#1)

• Slowly open the lower valve (#2)

• Water in the sight glass should lower.

• As the water in the sight glass lowers, the

pump should turn on.

• As the water continues to lower in the sight

glass, the burner should turn off.

• Slowly close the lower valve (#2).

• Close the upper valve (#1)

• The water level in the sight glass should rise, first

turning on the burner and then turning off the pump.

NOTE:

On manual reset models, the reset button

will need to be pressed after the water level has

been restored before the burner will operate.

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

!

CAUTION

NOTE

More frequent blow-down may be necessary

due to dirty boiler water and/or local codes.

Valve #2

Valve #1

NOTE

The control may need to be inspected and

cleaned more frequently on systems where there

is the potential of excessive scale or sludge

build-up. This includes systems:

• With high raw water make-up

• With no condensate return

• With untreated boiler water

• Where significant changes have been

made to the boiler-water chemical

treatment process

• With oil in the boiler water

NOTE

If this sequence of operation does not occur as

described, immediately close all the valves, turn off the

boiler and correct the problem. Inspection/cleaning of

the float mechanism may be required to determine why

the control was not working properly. Retest the control

after the problem has been identified and corrected.