10. CONFIGURATION OF THESIS 2.0 WITH OFF - LINE SOFTWARE

8. CONNECTIONS FOR MANUAL OR AUTOMATIC INTERLOCKING

8.1 CONNECTIONS EXAMPLE FOR MANUAL OR AUTOMATIC INTERLOCKING

7.1 RELAY CONFIGURATIONS

If the lock is used in a local setting (single door), it is possible to configure the relays using the

jumpers included in order to obtain one of the following signals:

“SECURED DOOR STATUS” (bolt out and door closed)

Note: this setting has already been preset by the manufacturer in all the locks

that use the “standard” setting software.

“MOTORISED DOOR OPENER COMMAND” (with bolt in, 1 second pulse)

Cut power, insert jumper JP1 as shown and restart power.

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

12345678

12345678

NOTE

If required by the specifications of the

system, connect the indicator lights to

the relay of the “secured door status”

of each lock (PIN 4/5/6) and the

corresponding opening button (PIN 7/8

optically insulated entry). Anticipate

the use of an adequate power supply

(one lock alone consumes 15W).

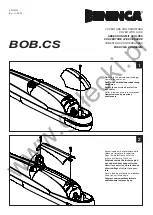

To obtain a manual or automatic interlocking between two Thesis 2.o solenoid locks

equipped with the appropriate software and connected with an encrypted communication

channel, proceed as follows:

1.

Connect the PIN1 of both locks (communication channel) with each other, as well as

the corresponding PIN2 and PIN3 with the same power source, but do NOT power: we

recommend that you do not insert the connectors already red in each lock (see figure

shown on the side).

2.

Insert the JP4 jumper in one of the two locks and by pressing either of the two

buttons of the same, only power this lock (insert the wired connector). Wait at least

2 seconds before releasing the button.

3.

Keeping the previously configured lock ON (step 4), locate the lock without the JP4

jumper; while pressing either of the two buttons, start power on this lock as well

(insert the wired connector). Wait at least 2 seconds before releasing the button.

4.

After a few seconds, the communication between the two locks will be activated, and

both locks will operate in the inte locking mode laid out by the software (manual or

automatic).

NOTE

The above procedures are performed with the doors in opened position.

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

9. CONFIGURATION OF THESIS 2.0 WITH STYLOS LINE

Configuration and access to address bus jumpers.

Remove the label (illustration on the side) to access

to the configuration jumpers (JP1/2/3/4).

After completing this operation replace the label.

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

JP4

JP3

JP2

JP1

ADDRESS 1

BUS ADDRESS

JUMPERS

ADDRESS 3

ADDRESS 5

ADDRESS 7

9.1 CONFIGURATION OF THESIS 2.0 WITH STYLOS LINE

Access to the programming buttons.

CAUTION

Position the lock to be with the bolt and the door

in opened position.

The electrical connectoins are described on paragraph 2

LEGEND:

P1/P2 = Programming buttons

L1 = LOCKBUS LED type I/II

Access to the programming buttons P1 and P2.

JP4

JP3

JP2

JP1

BUS

ADDRESS

1

2

3

4

5

6

7

8

JP 4

JP 3

JP 2

JP 1

Power supply 8/30 VDC - 15 W

1 2 3 4 5 6 7 8

LOCKBUS

(+) V ALIM

( ) GND

Note:

for each Lockbus

channel it’s possible to

connect max 8 Stylos readers.

Note:

Take off the label to enter into

configuration jumpers (JP1/2/3/4).

After the operation replace the label.

7. RELAY CONFIGURATIONS

Configuration and access to the programming relay.

Peel off label (illustration on the side) to access the

Jumper Configuration (JP1/2/3/4).

Once done, reposition the label.

JP4

JP3

JP2

JP1

NOTE

If jumper JP1 is off, the relay is

configured directly by the

settings of the lock software.

11. WARNINGS

Failure to comply with the instructions laid out in this manual will affect the proper functioning of the lock,

with consequent loss of warranty.

This product can only be used for what it was specifically designed to do. Any other use is considered

irregular and dangerous.

Provisions should be made to ensure that a suitable isolation and protection switch be placed upstream

of the power supply.

Do not use the lock as a drilling template.

Do not paint or lubricate the lock.

Always ensure the bolt is clean and free of friction. In case the valve needs to be cleaned, do not use

products that can leak into the lock.

We recommend you equip the door with a door closer to prevent rebound when closing the door.

If there is no power supply, the NC version of the solenoid lock can only be opened mechanically through

the cylinder or the handle (where applicable). On the other hand, the NA version of the solenoid lock

cannot be mechanically closed if there is no power supply.

ISEO spa is not required to comply with warranty conditions if the product has been subjected to changes,

repairs or alterations by unauthorized personnel.

For manufacturing and commercial reasons, or to improve the quality of its product, ISEO spa reserves the

right to make any changes it deems appropriate to the product and its instruction manual without prior notice.

EC Declarations of conformity available at:

https://www.iseo.com/it/en/download