Ironwood SLR305 | User Manual

21

8.0 Maintenance

WaRninG

Before performing any type of maintenance or adjustments, make

certain that the machine is disconnected from its power source and

completely shut off.

WaRninG

Never operate the machine until it has been properly lubricated and

all necessary maintenance work has been completed.

NOTE: After changing a setting, making an adjustment, performing

repair/maintenance work, or troubleshooting, please check that all

applicable safety functions are working properly before performing

another operation.

Clean all machinery parts and surrounding areas every day.

Keep a maintenance record and perform recommended

maintenance checks.

8.1 Automatic Lubrication System

Every day, check the oil level in the feed chain lubrication tank before

operating the machine. If the oil level is low or if the feed chain stops,

refill the oil reservoir immediately. Remove the oil cover and pour

the lubricant into the tank until it is 80% full. Do not let the lubricant

overflow. When pouring oil into the tank, be sure impurities and

debris do not get inside.

To order oil for the central lubrication device, call Stiles Machinery

at 1-800-727-8780. The central lubrication device uses the

following oil:

Viscosity

Ambient Temp. Shell Oil

ISO VG

32

0~5ºC

Tonna 32

VG32

68

5~40ºC

Tonna 68

VG68

Never use recycled oil.

Oil level gauge

Be sure the lubrication tank has an adequate supply of oil.

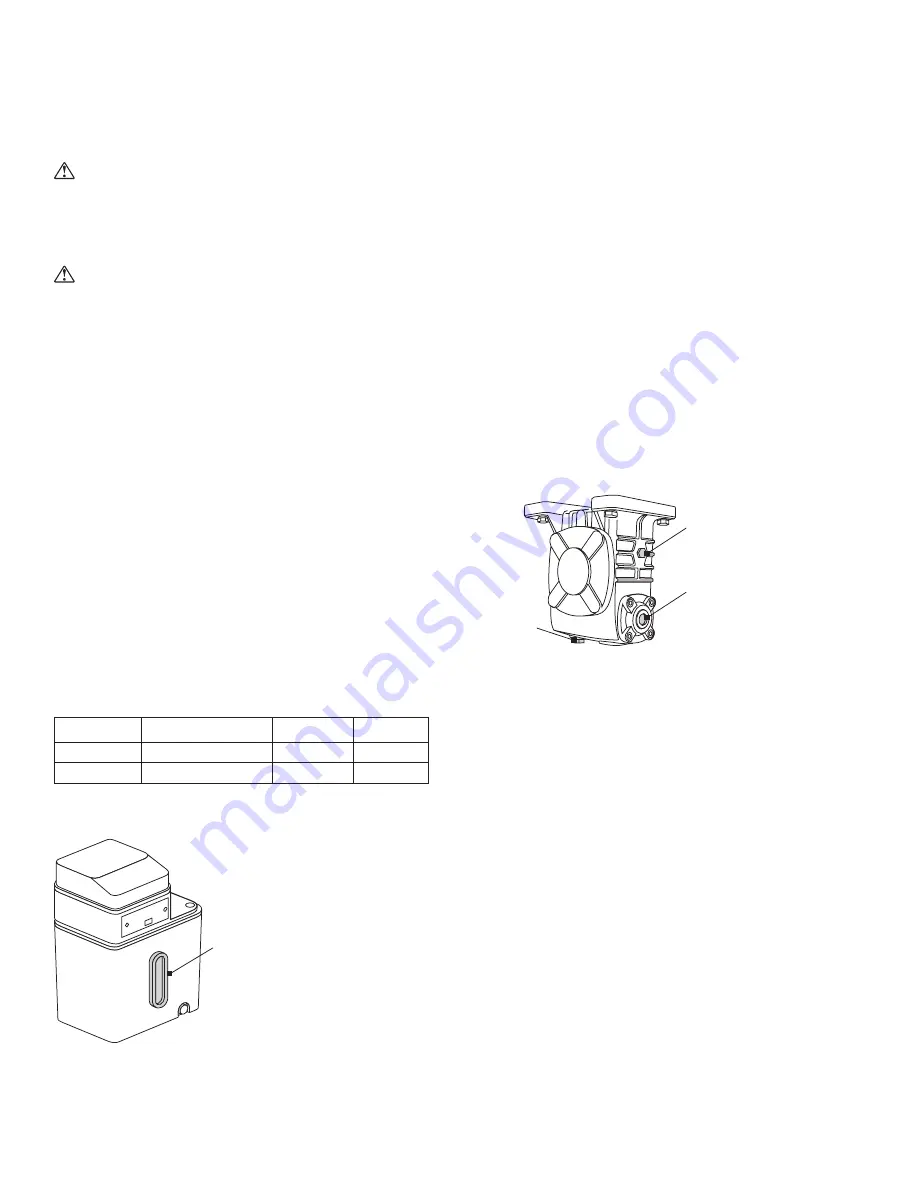

8.2 Manual Lubrication

After first 100 working hours

Change the oil for the feed-chain reduction gears.

1. Remove the oiler filler plug.

2. Loosen the oil discharge screw.

3. Drain all oil into a measurement cup. The same amount of oil

drained should be the same amount of oil used to refill the oil

reservoir.

4. Tighten the oil discharge screw.

5. Add oil to the oil inlet until it rises above the oil level window.

The gear reducer should have an oil level over half full.

Overfilling may cause leakage.

6. Change the oil again after every 2,500 working hours.

Covering screw

of the oil filter

Oil level

window

Oil discharge

screw-point