English

- 27 -

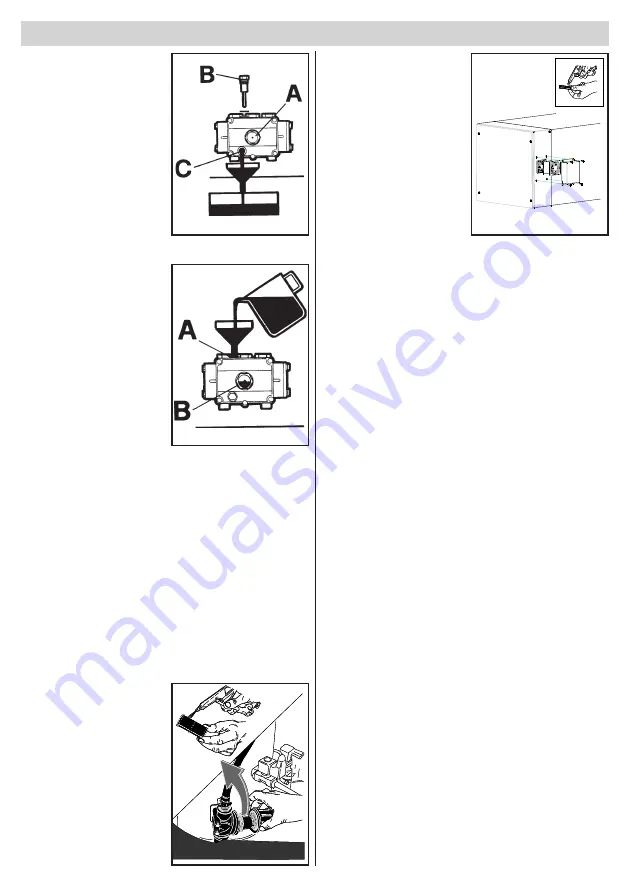

FIG.13

FIG.14

CHECKING PUMP OIL LE-

VEL AND OIL CHANGE

From time to time check the

oil level in the high pressure

pump by means of the sight

glass (fig. 13A) or the dipstick

(fig. 13B).

If the oil has a milky appearan-

ce, call the technical service

centre immediately.

Change the oil after the first

50 hours' work and subse-

quently every 500 hours or

once a year.

Proceed as follows:

1

) Unscrew the drain cap

situated under the pump (fig.

13C).

2

) Unscrew the cap with the

dipstick (fig. 13).

3

) Let all the oil drain off into a

container and deliver it to an

authorized oil collection and

disposal centre.

4

) Replace the drain screw

and pour fresh oil in through

the filling cap on top (fig.

14A) until it reaches the level

indicated on the sight glass

(fig. 14B).

For water cleaners without

oil drain bung, contact our

technical service centre for

replacement.

Use only SAE 15 W40 oil.

BOILER MAINTENANCE.

Empty the boiler using the

drain plug located on the bot-

tom of the cleaner.

On average, the boiler should

be serviced after every 200

hours of work.

The boiler must be descaled

by an authorised service cen-

tre only.

During descaling, the cleaner

will remain at the service cen-

tre.

CLEANING THE WATER

FILTER

Clean the water intake filter

regularly and free it from any

impurities (fig. 15).

CHANGING THE NOZZLE

The high pressure nozzle fitted on the lance must be changed

from time to time, as this component is subject to normal wear

during use. Wear may generally be detected by a drop in the

working pressure of the cleaner. To replace it, consult your

supplier and/or dealer for instructions.

FIG.16

CLEANING THE AIR

FILTER

Clean the air intake filter

regularly and free it from any

impurities (fig. 16).