16

TROUBLESHOOTING

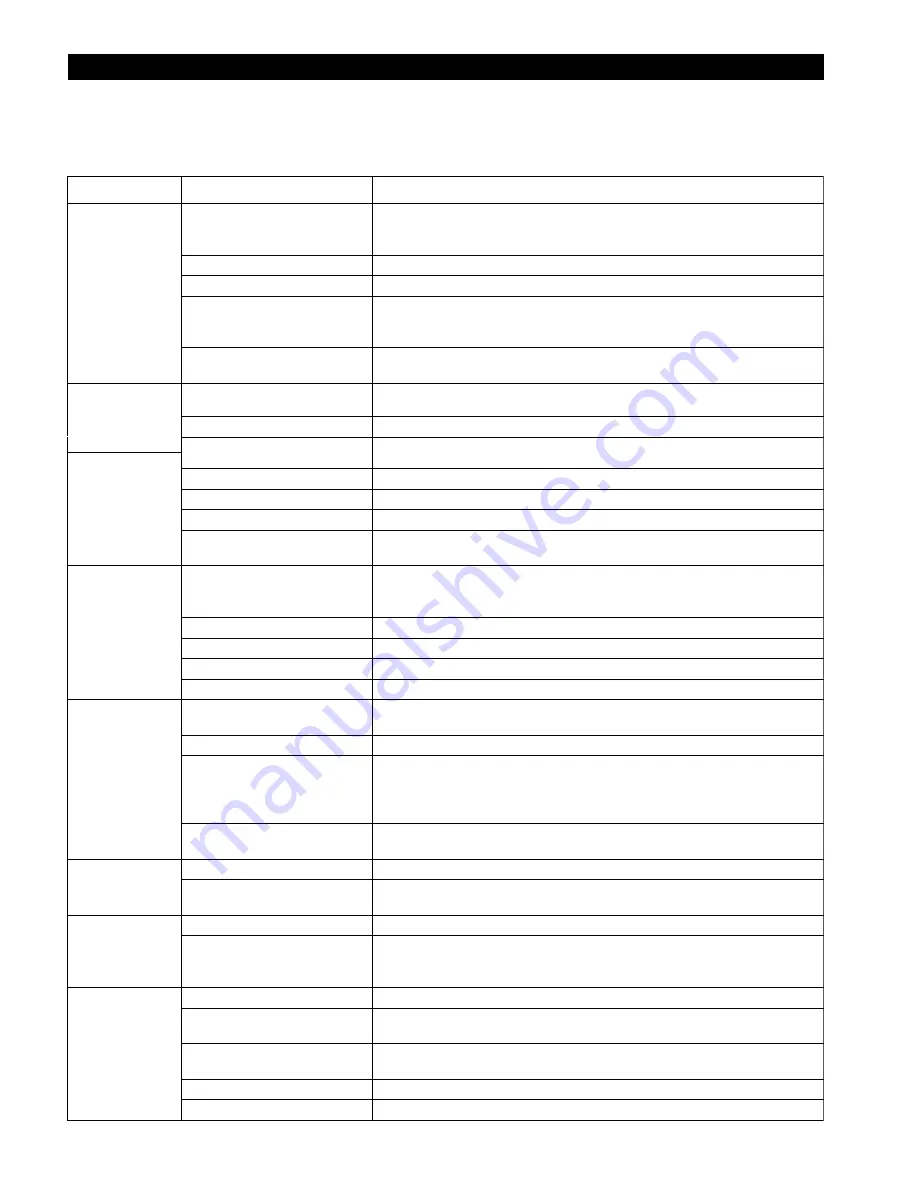

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections

performed by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to

common hoist symptoms, probable causes, and remedies.

SYMPTOM

CAUSE

REMEDY

Hoist will not

operate.

No air supply to hoist, or too little

flow or pressure.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

Hoist is overloaded.

Reduce load to within rated capacity.

Motor is damaged.

Disassemble, inspect and replace parts. Refer to “MAINTENANCE” section.

Pendant malfunction.

Check pendant throttle lever for free movement. Check air pressure at pendant.

Minimum operating pressure in pendant line must be 55 psig (3.8 bar/380 kPa).

Check lubricator oil level. Fill if low.

Brake not releasing.

Check brake release circuit and pressure. Minimum operating pressure at brake

inlet must be 55 psig (3.8 bar/380 kPa).

Load continues to

move when hoist is

stopped (UP

direction).

Valve or throttle lever sticking.

Check pendant throttle lever for free movement. Lubricate or repair as required.

Dump valves not releasing.

Check pendant hose dump valves.

Pendant lever sticking.

Check pendant throttle lever for free movement.

Load continues to

move when hoist is

stopped (DOWN

direction).

Dump valves not releasing.

Check pendant hose dump valves.

Hoist is overloaded.

Reduce load to within rated capacity.

Valve or throttle lever sticking.

Check pendant throttle lever for free movement.

Brake is slipping.

Check brake springs and brake disc linings for wear. Refer to “MAINTENANCE”

section.

Hoist does not lift

load.

No air supply to hoist, or too little

flow or pressure.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

Hoist is overloaded.

Reduce load to within rated capacity.

Main air travel is restricted.

Check throttle lever and linkage for free, unobstructed movement.

Exhaust restricted.

Inspect vents and replace mufflers. Refer to “MAINTENANCE” section.

Motor is damaged.

Disassemble, inspect and replace parts. Refer to “MAINTENANCE” section.

Reduced speed

and/or capacity.

Inlet stud (24) screen plugged,

restricting air flow.

Replace old style inlet stud with screen with new style (without screen), or

remove screen.

Lubricator oil level low.

Fill lubricator.

No air supply to hoist, or too little

flow or pressure.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance. Check pendant

control adjustment as described in the “INSTALLATION” section.

Bleed screws out of adjustment.

Adjust bleed screws as described in ‘Bleed Screw Adjustment’ procedure in

“INSTALLATION” section.

Hoist operates in

LOWER direction

but will not LIFT.

Hoist is overloaded.

Reduce load to within rated capacity.

Pendant malfunction.

Check pendant throttle lever for free movement. Check air pressure at pendant.

Minimum operating pressure in pendant line must be 55 psig (3.8 bar/380 kPa).

Hoist operates in

LIFT direction but

will not LOWER.

Brake piston seals leaking.

Install new seals. Refer to “MAINTENANCE” section.

No air supply to hoist, or too little

flow or pressure.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

Load chain jumps

on sheave or makes

a “snapping”

sound.

Dirty or lack of oil on load chain. Clean and lubricate load chain. Refer to “LUBRICATION” section.

Worn or rusted load chain.

Inspect load chain. Refer to “INSPECTION” section. Clean and lubricate load

chain. Refer to “LUBRICATION” section.

Worn load sheave or incorrectly

reeved load chain.

Check load chain is correctly reeved. Disassemble, inspect and replace worn

parts. Refer to “MAINTENANCE” section.

Capsized hook.

Correct as described in “MAINTENANCE” section.

Hoist not in-line with load.

Align hoist with load. Do not side pull or “yard”.

Содержание HL1000K

Страница 33: ...33 HOIST PARTS SECTION GUIDE ...

Страница 34: ...34 HOIST HOUSING ASSEMBLY PARTS DRAWING ...

Страница 36: ...36 HOIST VALVE CHEST ASSEMBLY PARTS DRAWING ...

Страница 38: ...38 HOIST GEARING ASSEMBLY PARTS DRAWING ...

Страница 40: ...40 HOIST BRAKE ASSEMBLY PARTS DRAWING ...

Страница 44: ...44 HL1000K HL1000KR AND HL1500K HOOK ASSEMBLY PARTS DRAWING ...

Страница 46: ...46 HL2000K AND HL3000K HOOK ASSEMBLY PARTS DRAWING ...

Страница 48: ...48 HL4500K HOOK ASSEMBLY PARTS DRAWING ...

Страница 50: ...50 HL6000K HOOK ASSEMBLY PARTS DRAWING ...

Страница 52: ...52 PENDANT ASSEMBLY PARTS DRAWING ...

Страница 54: ...54 FABRIC CHAIN CONTAINER ASSEMBLY PARTS DRAWING ...

Страница 56: ...56 METAL CHAIN CONTAINER ASSEMBLY PARTS DRAWING ...