4

INSTALLATION

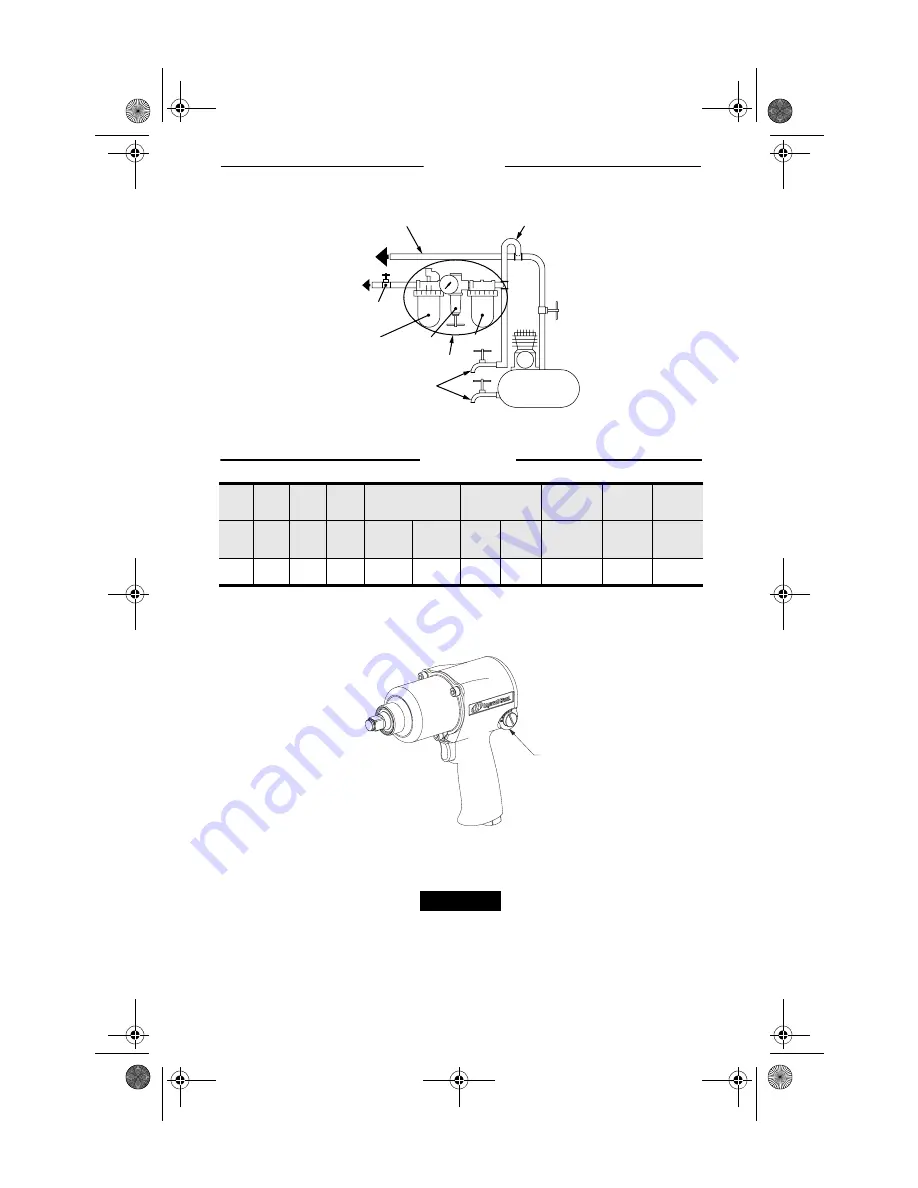

(Dwg. TPD905-2)

SPECIFICATIONS

■

Tested in accordance with PNEUROP PN8NTC1

♦

Tested to ISO8662-7

•

Tested to ISO3744

(Dwg. TPD2038)

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

When the life of the tool has expired, it is recommended that the tool be disassembled,

degreased and the parts be separated by material so that they can be recycled.

F

L

R

Main Line(s) Inner Ø

to be 3X Size of

Air Tool's Inlet Ø

To Air

System

To Air

Tool

Lubricator

Emergency

Shut-Off

Valve

Regulator

Filter

Compressor

FRL

Drain Regularly

Branch Line(s) Inner Ø

to be 2X Size of

Air Tool's Inlet Ø

Model

Handle

Drive

Impacts

/ min.

Recommended

Torque Range

■

Sound Level

dB (A)

♦

Vibrations

Level

Inlet

Connection

(Thread)

Minimum

Inside Ø

(Air Hose)

I.D.

Type

in

2

bpm

Forward

ft•lbs

(N•m)

Reverse

ft•lbs

(N•m)

Pressure

•

Power

m/s

2

NPT

in (mm)

231G

pistol

1/2” 1,200

25 to 300

(34 to 407)

25 to 350

(34 to 475)

94.5

107.5

4.7

1/4

3/8 (10)

231G

5 Letter

Date Code

location

SR __ __ __

NOTICE

P7631eng.fm Page 4 Friday, May 23, 2003 8:04 AM