57

XtrapulsCD1-a

Chapter 8 - Appendix

12

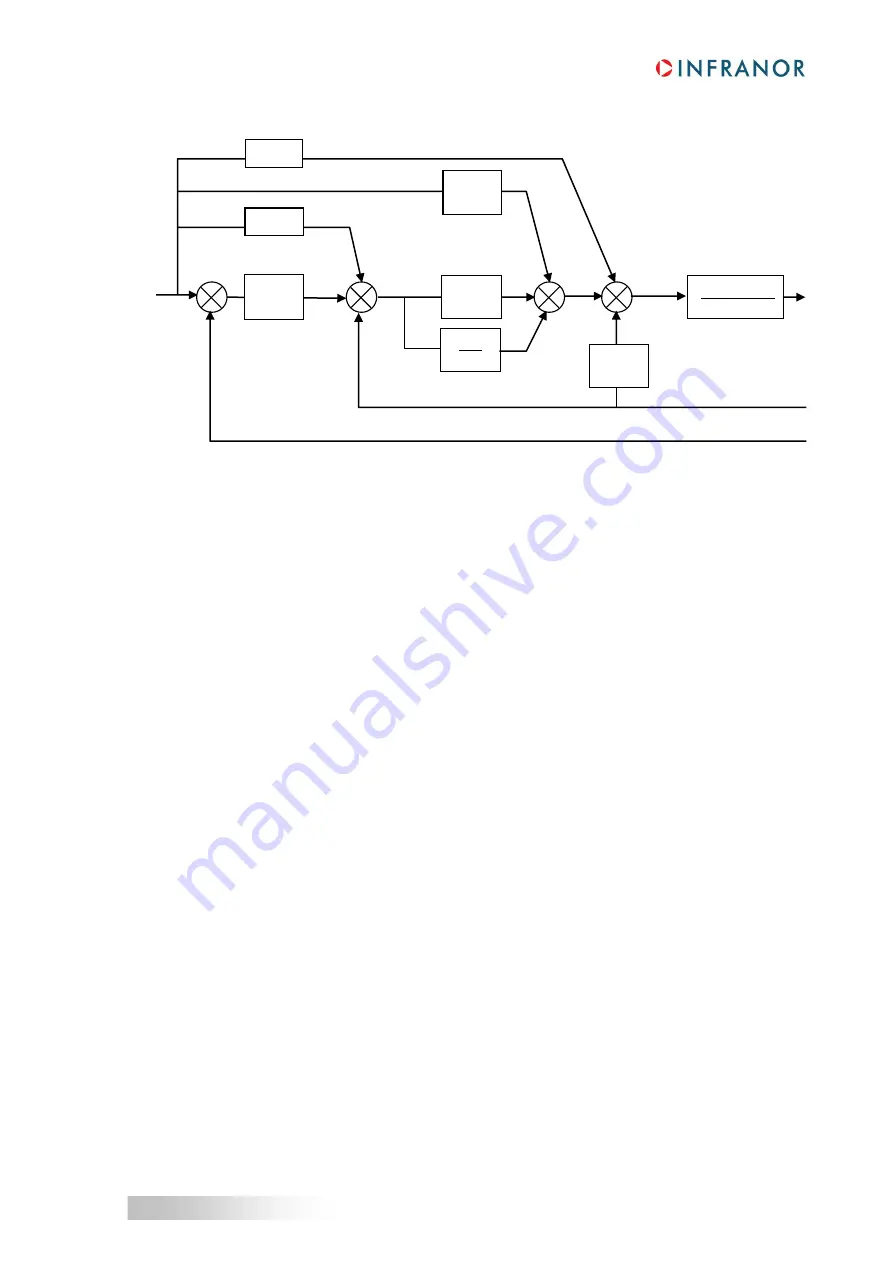

– SERVO CONTROLLER STRUCTURE

Speed error low-pass filter (Fev): defines the cut-off frequency at -3dB of the first order filter which acts on the

current command (Idc). This value is calculated by the drive during the auto tuning procedure and depends on the

selected bandwidth and the selected filter type.

Proportional speed gain (KP2): defines the proportional gain of the controller which acts on the speed error. Its

value is calculated by the drive during the auto tuning procedure. It can then be modified by the user if required.

Integral speed gain (KI): defines the integral gain of the controller which acts on the speed error. Its value is

calculated by the drive during the auto tuning procedure. It can then be modified by the user if required

Damping gain (KC): defines the proportional gain of the controller which acts only on the speed feedback. Its

value is calculated by the drive during the auto tuning procedure. It can then be modified by the user if required.

Proportional position gain (KP1): defines the proportional gain of the controller which acts on the position error. Its

value is calculated by the drive during the auto tuning procedure. It can then be modified by the user if required.

Feedforward speed 1 gain (KF1): defines the feedforward speed amplitude corresponding to the speed input

command. This term allows reducing the following error during the motor acceleration and deceleration phases. Its

value is set at 1 after the auto tuning procedure if minimum following error is required. It can then be modified by

the user if required.

Feedforward speed 2 gain (KF2): defines the feedforward speed amplitude corresponding to the viscous frictions.

This term allows reducing the viscous frictions effect during the motor acceleration and deceleration phases. The

gain value is equal to the damping gain value + the viscous friction compensation term. After the auto tuning

procedure, the feedforward speed 2 gain is set equal to the damping gain value if minimum following error is

required. The viscous friction compensation term can be calculated by measuring the current / speed ratio at

various motor speed values.

Feedforward acceleration gain (KA): defines the feedforward acceleration amplitude corresponding to the

acceleration input command. This term allows reducing the following error during the motor acceleration and

deceleration phases. Its value is calculated by the drive during the auto tuning procedure if minimum following

error is required. It can then be modified by the user if required.

The auto tuning procedure identifies the characteristics of motor and load and calculates the controller gains.

During the procedure, various choice are available to the user.

The choice of the time interval for speed measurement (speed measurement filter) allows the selection of the

speed measurement resolution value according to the position sensor resolution value: speed resolution (rpm) =

60000/ position sensor resolution / time interval (ms). The higher the time interval value, the better the resolution,

but also the lower the servo loop gains because of the increased speed measurement delay.

The choice of the anti-resonance filter is necessary in case of loud noise in the motor due to the motor/load

coupling elasticity.

The choice of the maximum stiffness filter allows a maximum stiffness on the motor shaft with regard to the torque

disturbances. However, this choice is only possible without any resonance due to the motor/load coupling

elasticity.

KA.s

2

KF1.s

KF2.s

KP2

KI

s

KC

2 .

. Fev

s+2.

. Fev

KP1

_

_

+

-

_

-

-

+

+

+

+

+

+

+

Position

reference

Idc

Speed

Position